Substrate-integrated electric dipole antenna and array based on low-profile microstrip feed structure

A technology of microstrip feeding and integrating galvanic couples, which is applied in antenna arrays, antennas, resonant antennas, etc., can solve the problems of narrow bandwidth, difficulty in direct integration of millimeter-wave front-end circuit chips, and increased complexity, etc., to achieve impedance bandwidth flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical solution disclosed in the present invention, the technical solution of the present invention will be further introduced below in conjunction with specific implementation methods and accompanying drawings.

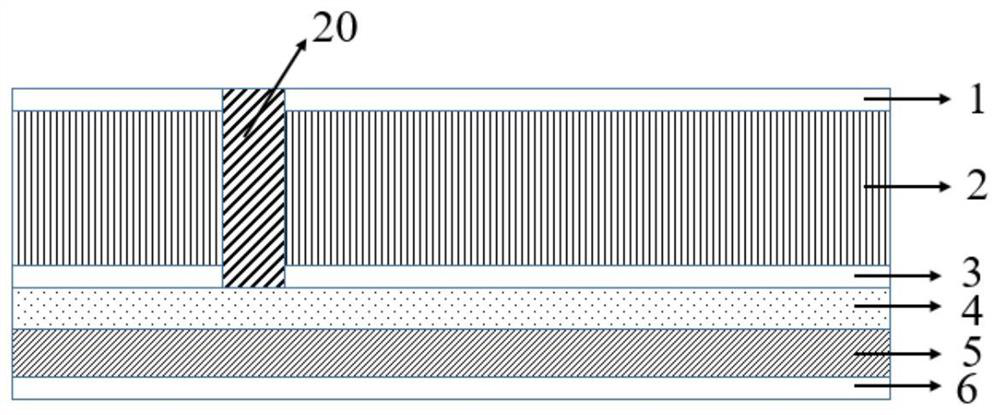

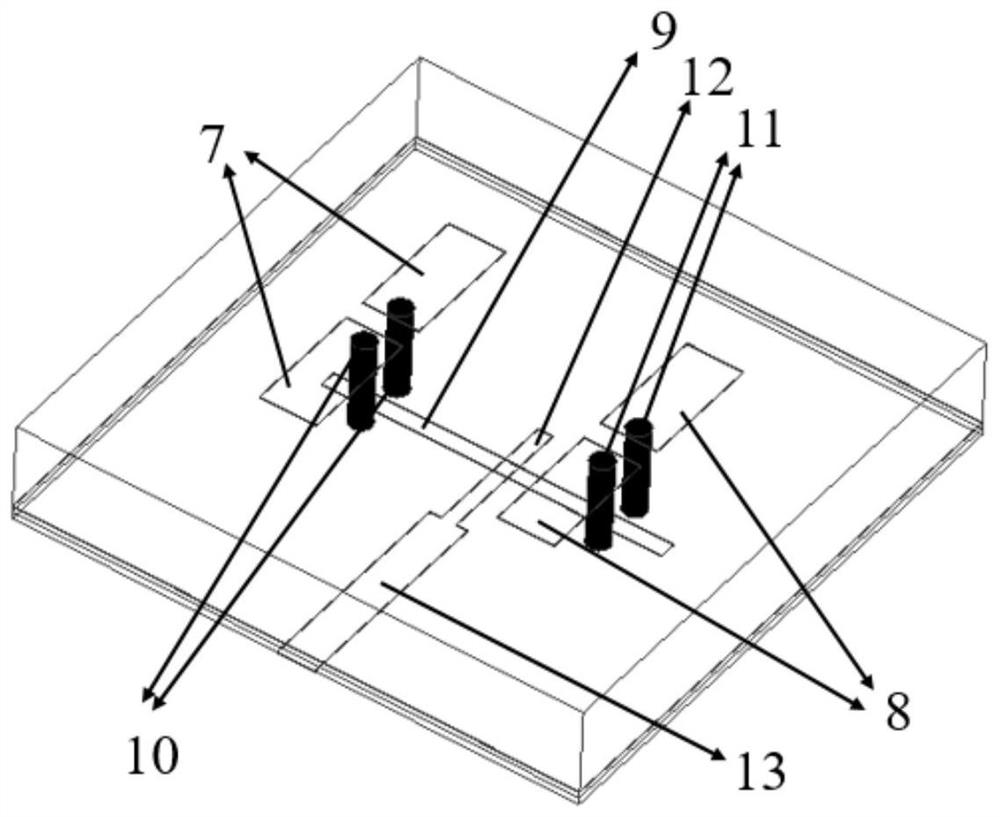

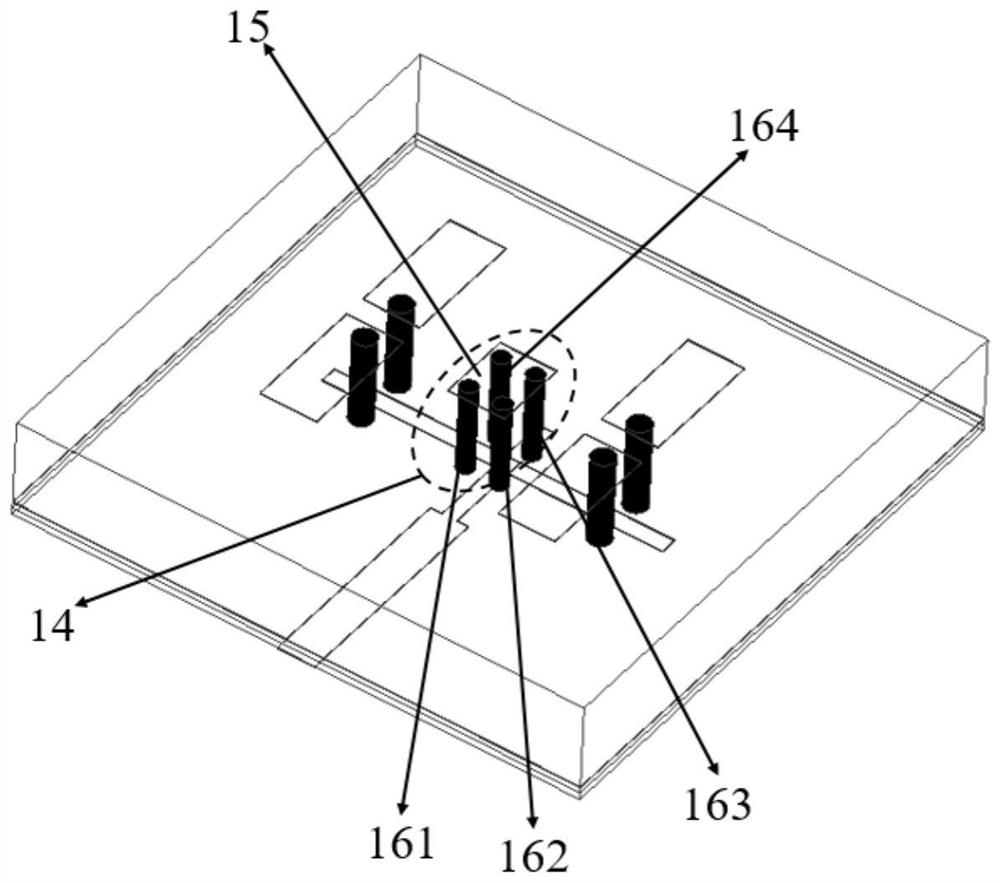

[0025] This specific embodiment discloses a substrate-integrated magnetoelectric dipole antenna based on a low-profile microstrip feed structure, such as Figure 1-Figure 2 As shown, it includes the top metal layer 1, the first dielectric layer 2, the middle metal layer 3, the second dielectric layer 4, the third dielectric layer 5 and the bottom metal layer 6 arranged in sequence from top to bottom, wherein the top metal layer 1 There is a pair of printed electric dipoles on it, including the first group of electric dipoles 7 and the second group of electric dipoles 8, the middle metal layer 3 is the ground layer, and the excitation printed electric dipoles are etched on it. The rectangular slots 9 of the printed circuit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com