Purification method of organic substance used as material of organic light-emitting element

A technology of organic light-emitting elements and organic substances, which is applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve problems such as uneven brightness, unstable evaporation speed, and reduced production efficiency, so as to improve the process speed and evaporation Stabilization of plating speed and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

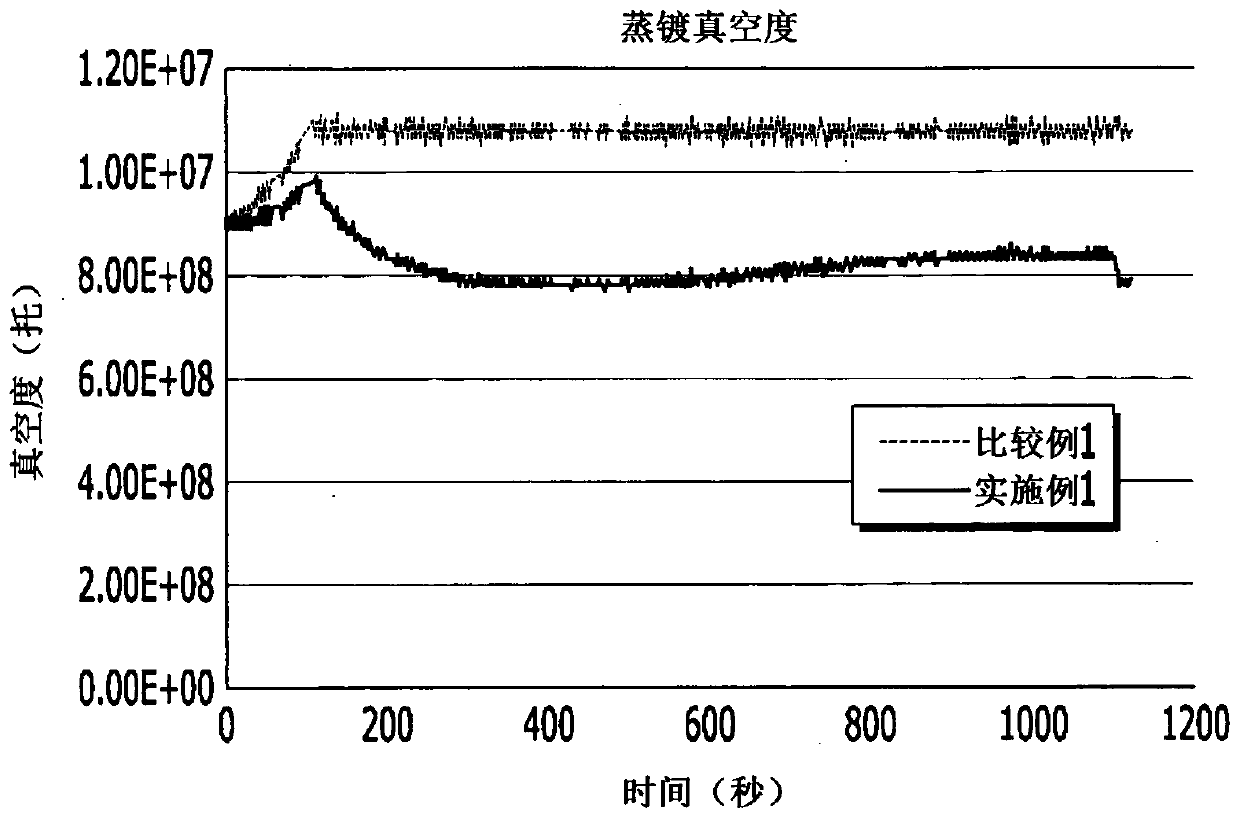

Embodiment 1

[0064] 1) Purification process of organic substances (CPL) as the material of the covering layer

[0065] Utilize DSC (Differential scanning calorimetry, differential scanning calorimetry) and TGA (Thermogravimetric analysis, thermogravimetric analysis) to the compound represented by following chemical formula CPL respectively measure melting temperature (Tm) and 1% thermal decomposition temperature (Td1%) . Specifically, DSC Q100 V9.6Build 290 was used as the DSC device, and Q500 was used as the TGA device. As a result of the measurement, it was confirmed that the melting temperature was about 320°C and the 1% thermal decomposition temperature was 382°C.

[0066]

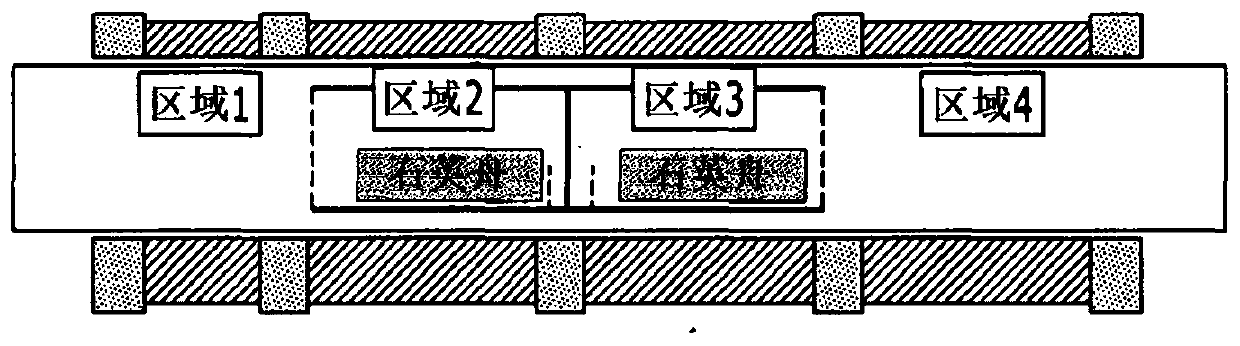

[0067] 4 kg of the above-mentioned compound was put into the cartridge of the sublimation purification apparatus to be sublimated and purified. Then, the inner tube and the outer tube were disassembled, and the organic matter crystallized on the wall surface of the inner tube was scraped and recovered. figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com