Liquid degassing device and method capable of automatically and continuously providing degassed liquid

A degassing and liquid degassing technology, which is applied in the field of liquid degassing and physical degassing devices, can solve the problems of high-power vacuum pumps, etc., and achieve considerable economic benefits, stable operation, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

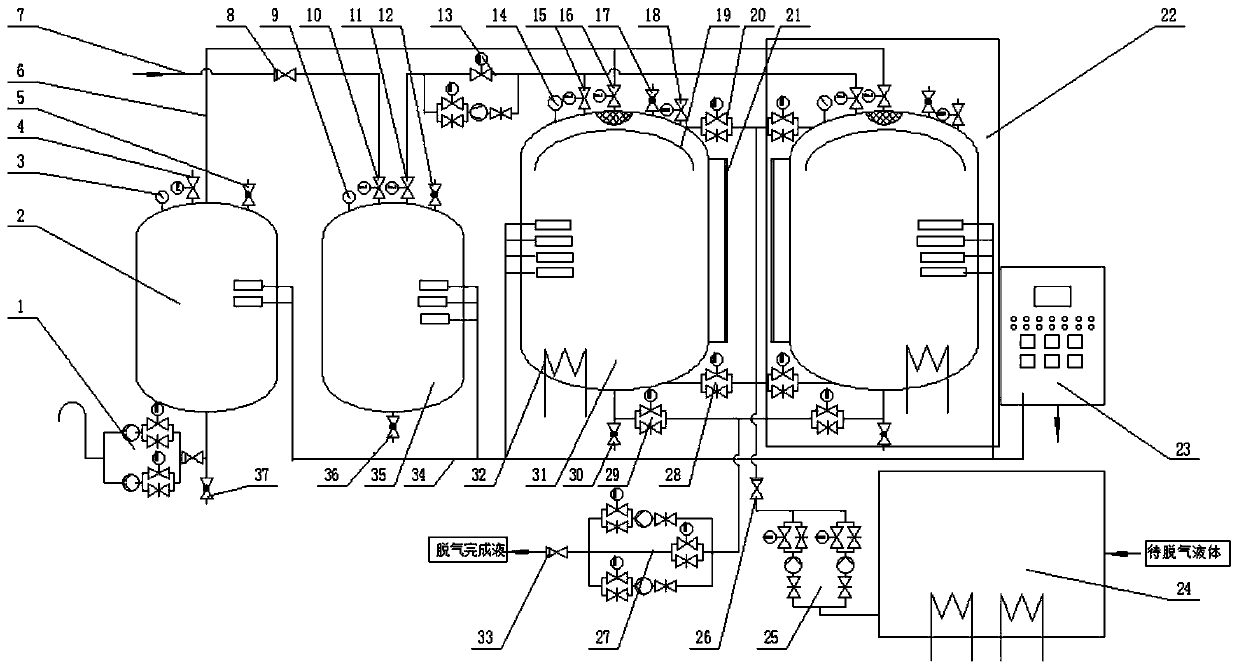

[0024] Such as figure 1 As shown, a liquid degassing device that can automatically and continuously provide degassing liquid, consists of a vacuum system, a protective gas system, a gas removal system, a liquid storage and transfer system and a control system;

[0025] The vacuum system consists of a vacuum pump 1, a vacuum tank 2, a vacuum pipeline 6 and related valve groups; the vacuum tank 2 is connected to the vacuum pump 1 and the degassing tank 31 respectively through the vacuum pipeline 6; the vacuum tank is provided with a vacuum / pressure gauge 3 and a vacuum tank The top automatic emptying valve 4, the vacuum tank top manual emptying valve 5; the bottom of the vacuum tank 2 is provided with a vacuum tank drain valve 37; in addition, the vacuum tank 2 is also provided with a temperature sensor and a pressure sensor.

[0026] After the system runs, a negative pressure is formed and maintained in the vacuum tank 2 and the vacuum pipeline 6. Once the degassing tank 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com