Latent curing agent type single-component polyurethane waterproof coating

A polyurethane waterproof and latent curing agent technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems affecting coating construction, etc., and achieve the effect of slow viscosity increase and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

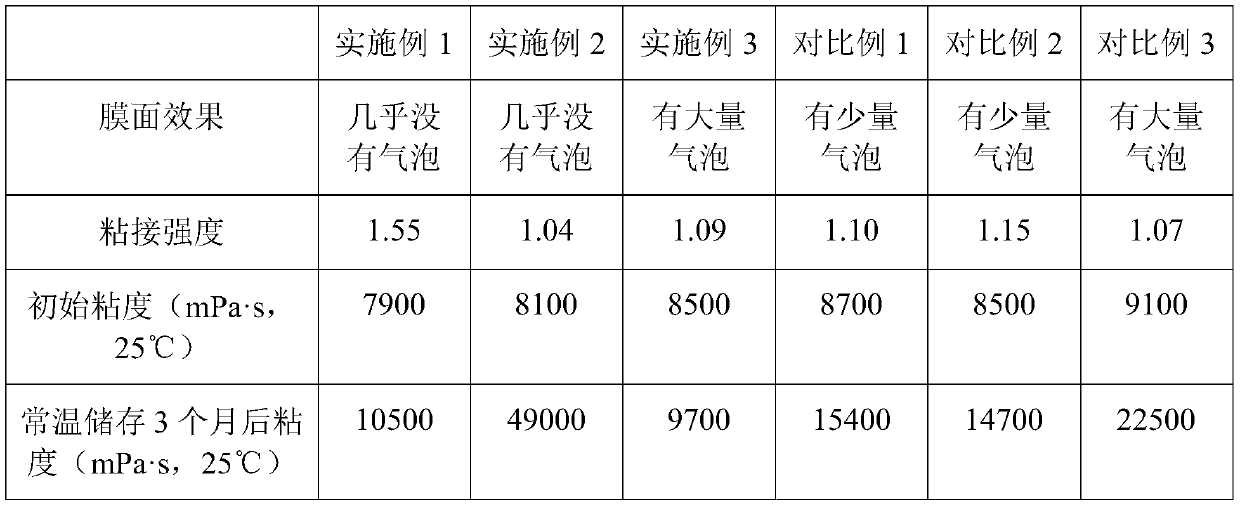

Examples

Embodiment 1

[0042] Add polyether polyols, chlorinated paraffins, and fillers according to the weight parts given in Table 1 into the mixing reactor, and then dehydrate the mixture at a temperature of 120°C for 3 hours, and measure the water content in the system by the Karl Fischer method to be less than or equal to After 200ppm, lower the temperature of the reactor to 70°C, add polyisocyanate, wait for the temperature to stabilize and raise the temperature to 80°C, react for 3 hours, then lower the temperature to 70°C, react for 1 hour, then raise the temperature to 80°C again, and react for 2 hours , lower the temperature to 60°C, add catalyst, react for 1 hour, add latent curing agent, diluent and defoamer, react for 1 hour, cool to 50°C and discharge.

Embodiment 2 and Embodiment 3

[0043] Parts of Example 2 and Example 3,

[0044]Among the polyether polyols used, polyether diols (Yantai Wanhua C2056) and polyether trihydric alcohol (Yantai Wanhua F3135) weight ratio is 10:8;

[0045] In the filler adopted, the weight ratio of heavy calcium carbonate and carbon black is 37:3;

[0046] The latent curing agent used is Qingdao Hengke MS-201 latent curing agent.

Embodiment 2

[0048] Add 10 parts by weight of polyether polyol, 10 parts by weight of chlorinated paraffin and filler into the mixing reactor, then dehydrate the mixture at 120°C for 3 hours, and measure the water content in the system by Karl Fischer method to be less than or equal to 200ppm Finally, lower the temperature of the reactor to 70°C, add 30 parts by weight of polyisocyanate, wait for the temperature to stabilize and raise the temperature to 80°C, react for 3 hours, then cool down to 70°C, react for 1 hour, then raise the temperature to 80°C again, React for 2 hours, cool down to 60°C, add 0.01 parts by weight of catalyst, react for 1 hour, add 5 parts by weight of latent curing agent, 2.5 parts by weight of diluent and 0.1 parts by weight of defoamer, react for 1 hour, cool to Discharge after 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com