Test device and method for detecting bonding strength of semiconductor device

A testing device and technology for bonding strength, applied in the field of testing devices for testing the bonding strength of semiconductor devices, can solve problems such as measurement failure, and achieve the effects of reducing cutting force, small deformation, and ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

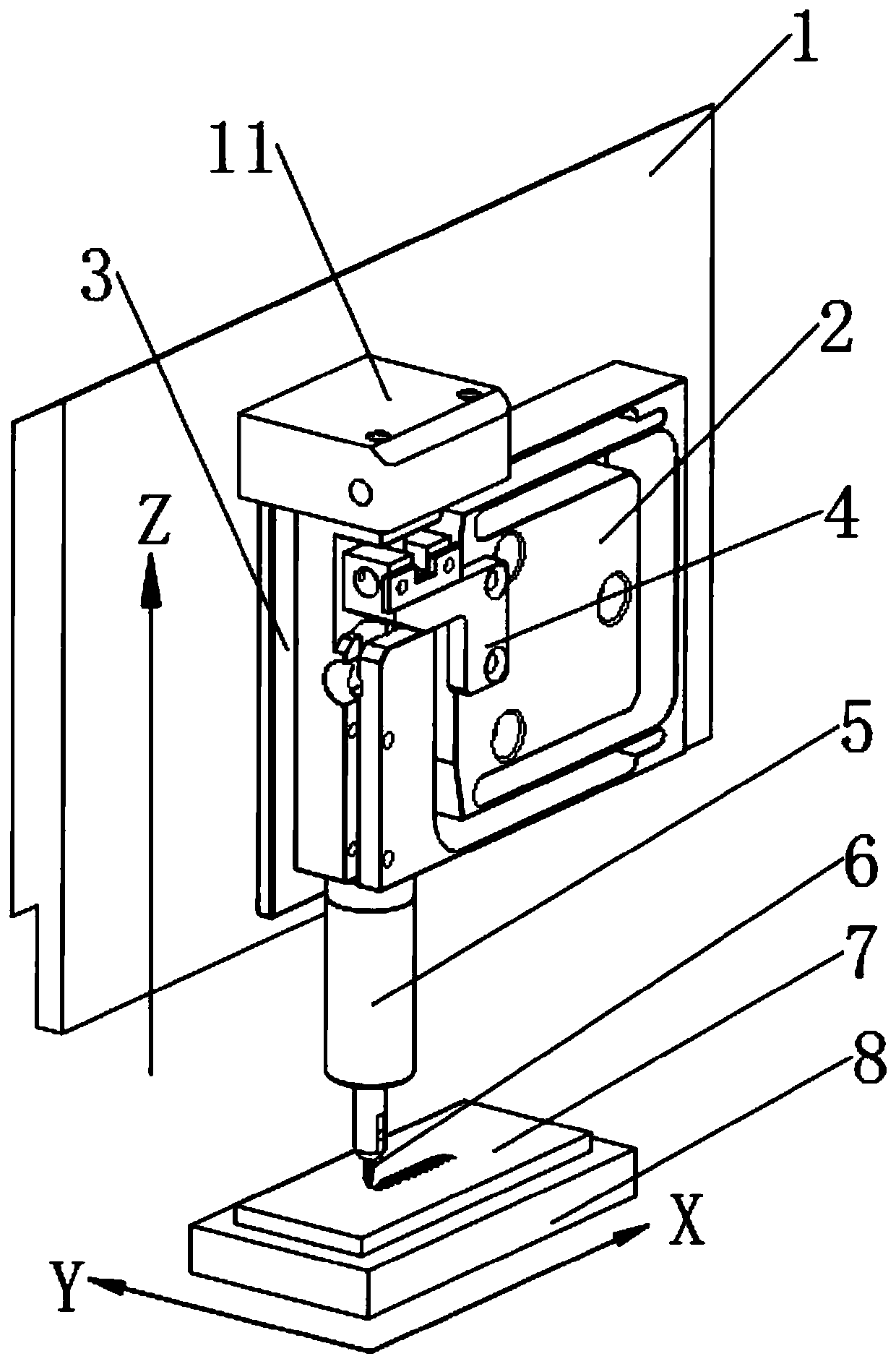

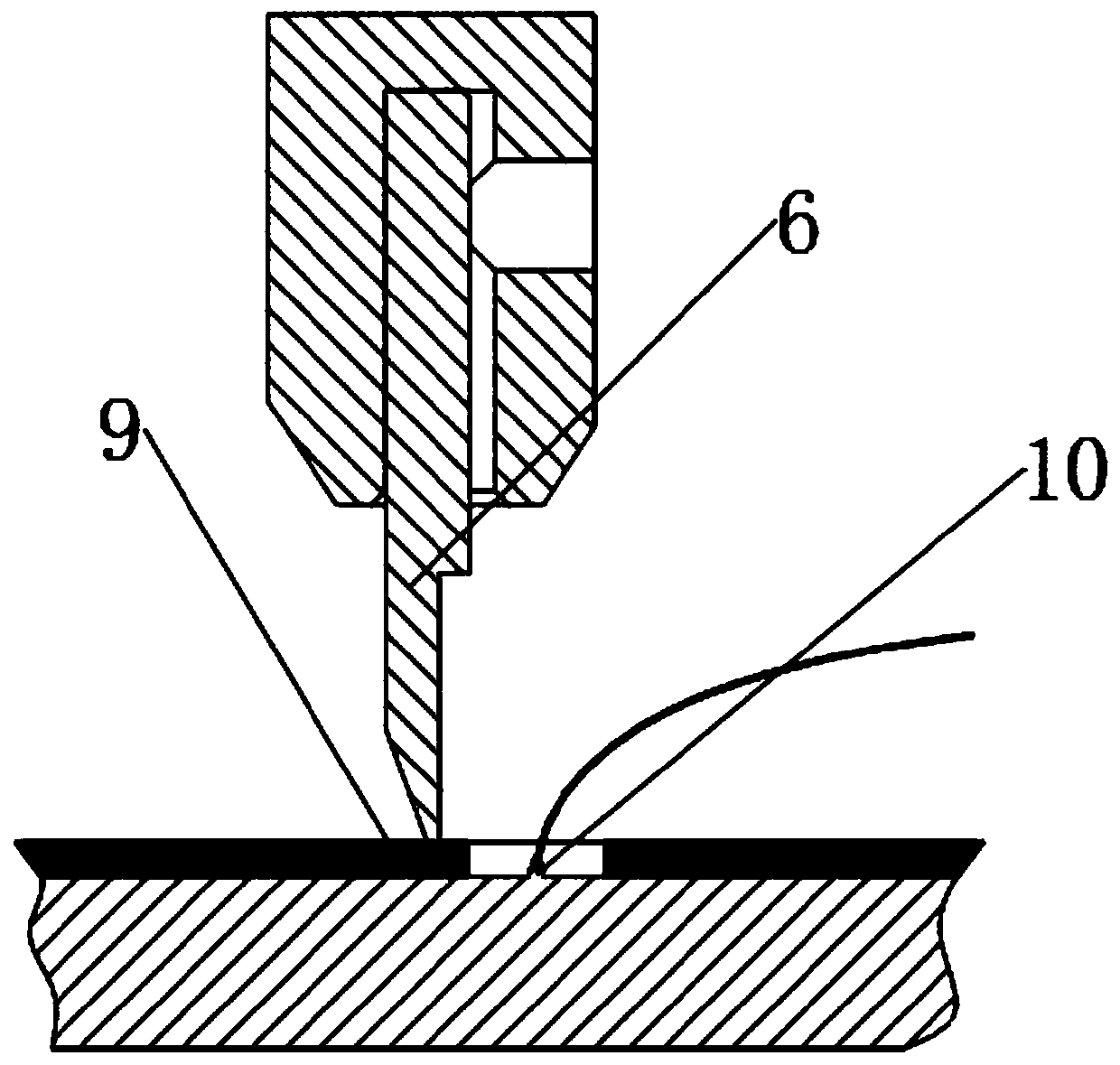

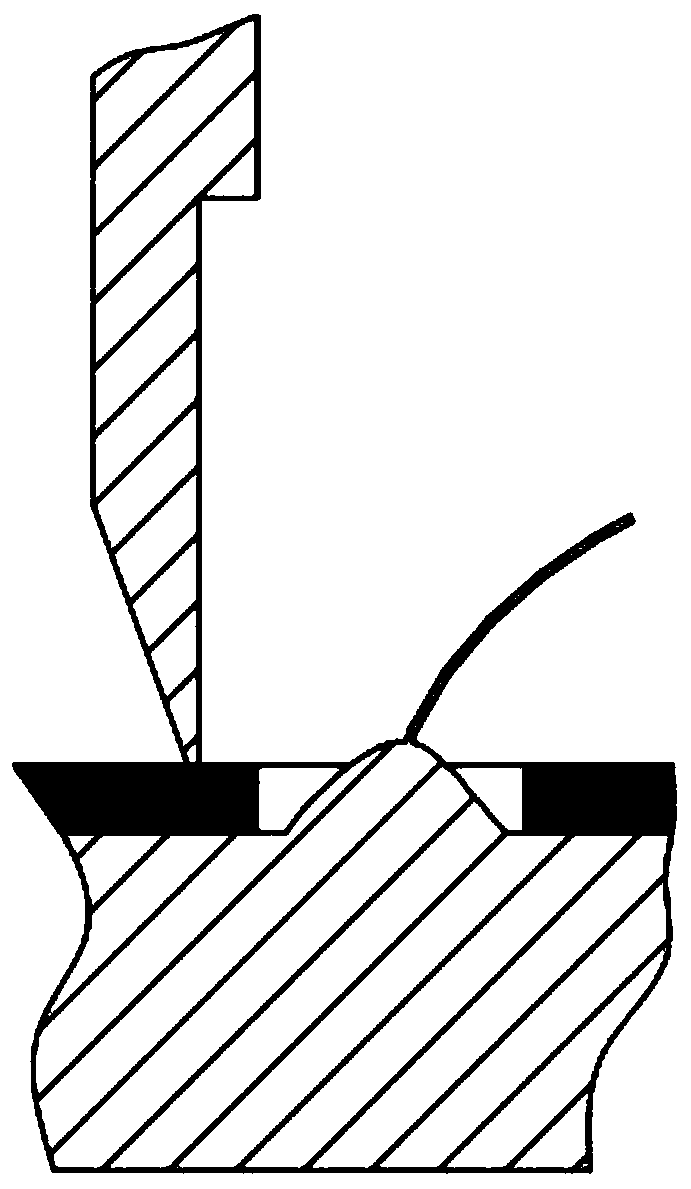

[0031] by figure 1 As shown, a testing device for detecting the bonding strength of a semiconductor device includes a mounting board 1 for fixedly mounting the testing device. The mounting board 1 is fixedly mounted on a controllable drive device that can move along the Z axis. This embodiment Among them, the controllable drive equipment model is MFM1200L shear force tester sold by Deruiyin Precision Technology Co., Ltd. The mounting plate 1 is fixedly installed with a composite cantilever beam 2 with horizontal position offset compensation, and the composite cantilever beam 2 is an existing Technology, the composite cantilever beam 2 is provided with a free end and a fixed end. The free end and the fixed end of the composite cantilever beam 2 are fixedly connected with a contact sensor 4 for detecting the downward pressure of the tool. The contact sensor 4 is a pressure-sensitive pressure sensor. The contact sensor 4 includes a photoelectric sensor and a photoelectric blocking ...

Embodiment 2

[0044] by figure 1 As shown, a testing device for detecting the bonding strength of a semiconductor device includes a mounting board 1 for fixedly mounting the testing device. The mounting board 1 is fixedly mounted on a controllable drive device that can move along the Z axis. This embodiment Among them, the controllable drive equipment model is MFM1200L shear force tester sold by Deruiyin Precision Technology Co., Ltd. The mounting plate 1 is fixedly installed with a composite cantilever beam 2 with horizontal position offset compensation, and the composite cantilever beam 2 is an existing Technology, the composite cantilever beam 2 is provided with a free end and a fixed end. The free end and the fixed end of the composite cantilever beam 2 are fixedly connected with a contact sensor 4 for detecting the downward pressure of the tool. The contact sensor 4 is a piezoelectric pressure sensor. The contact sensor 4 detects the contact force between the test tool 6 and the sample 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com