Method of assessing electro-static discharge sensitivity of flat panel display product in manufacture

An electrostatic discharge and flat-panel display technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as ESD risk situations that are difficult for FPD products, and achieve the effect of electrostatic protection protection goals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

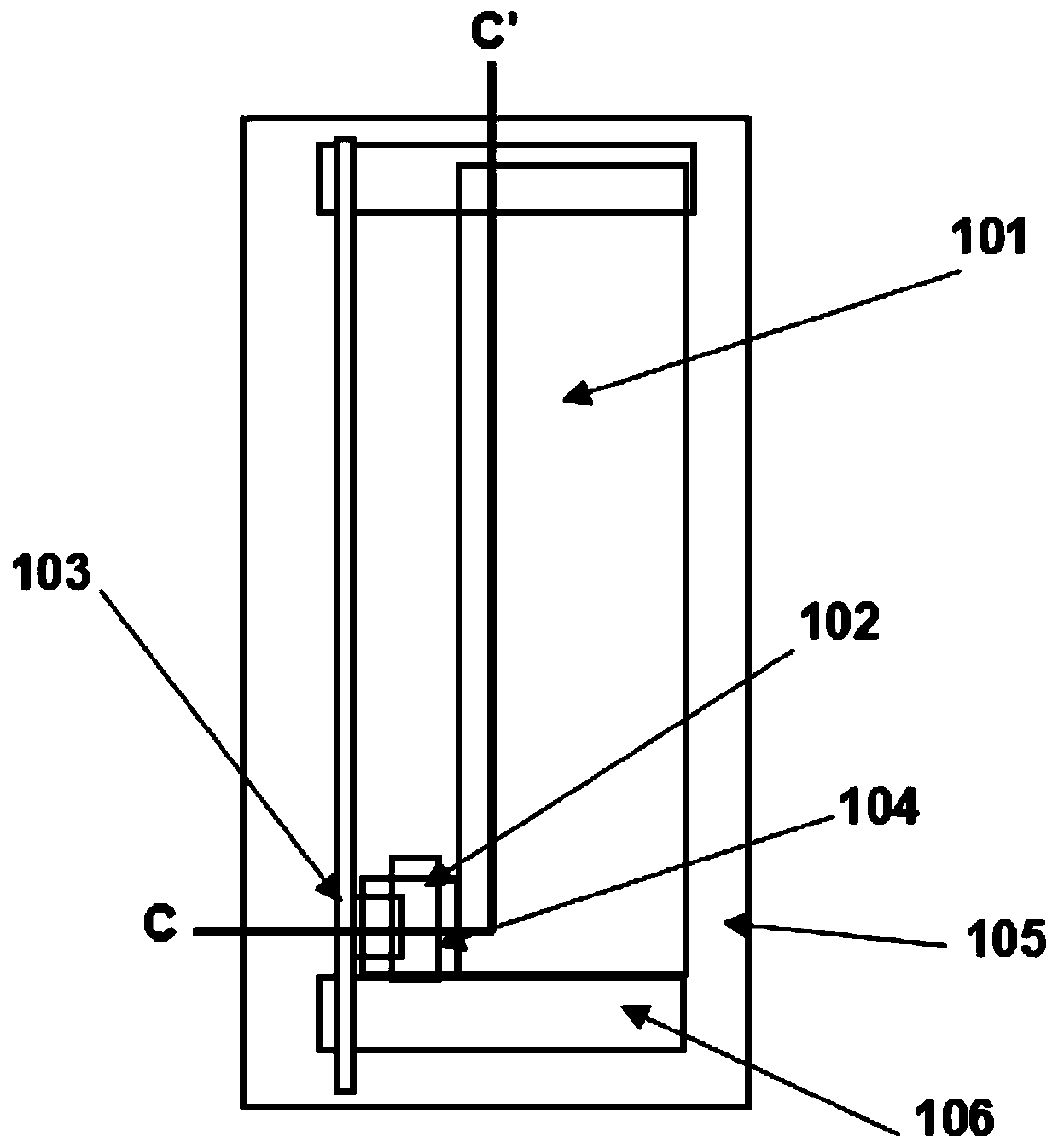

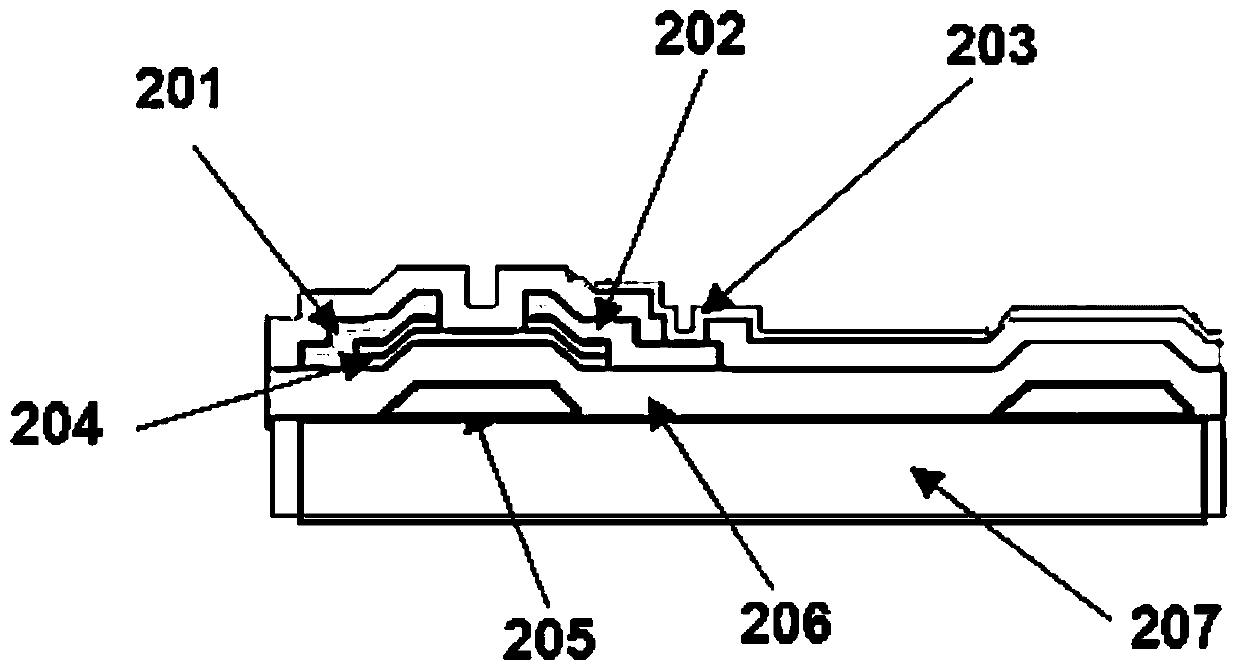

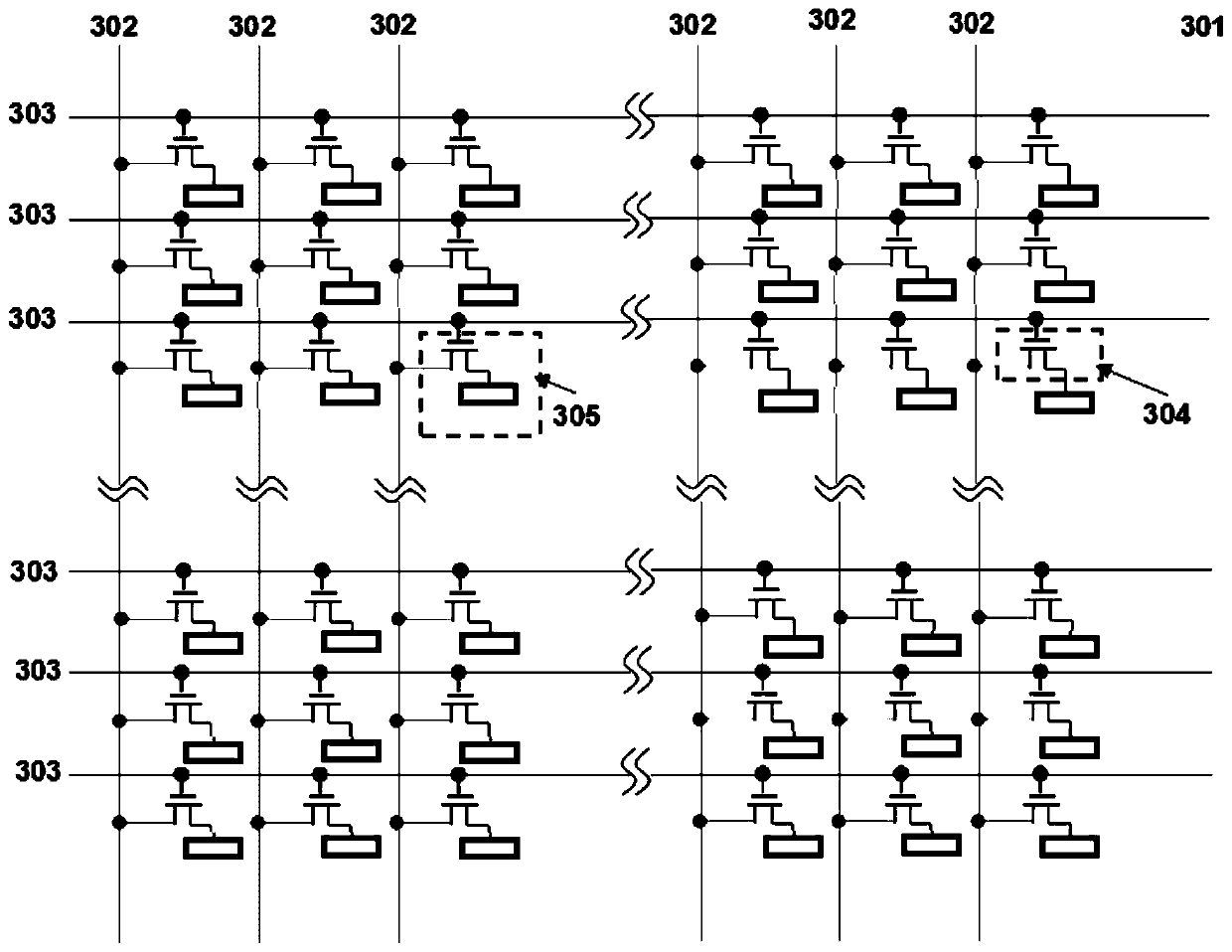

[0043] Example 1: See Figure 1-13 , a method for assessing the electrostatic discharge susceptibility of flat panel display products in manufacturing, comprising the following steps:

[0044] A. Establish a simulation model of the electronic device structure of the FPD product in the front-end manufacturing process. Figure 8 In this invention, for simulating the front-end production process of FPD products, especially one type of main ESD failure situation in the TFT Array section-the ESD failure type between different metal film layers of TFT, the invention is related to the ESD risk of the corresponding production process Matched TFT device simulation model. The claims involved in this invention include: 1. Use the cross shape and stacked structure to simulate the ESD failure structure characteristics between different metal film layers in TFT devices in FPD products; 2. The ESD evaluation application range of FPD products includes TFT-LCD , rigid AMOLED (Active Matrix O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com