Coating liquid for reconstituted tobacco and preparation method of coating liquid

A technology for reconstituted tobacco leaves and coating liquid, which is applied in the fields of tobacco, application, and treatment of tobacco, and can solve problems affecting the processing adaptability and sensory quality of tobacco leaves, blocking the evaporation of substrates, and the adhesion of finished tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] (1) Preparation of blank coating liquid: extract 10 g of tobacco stems (place of origin: Yunnan) with 500 g of water, the extraction temperature is 80 ° C, the extraction time is 20 min, filter to obtain the filtrate, and concentrate the filtrate to a density of 1.3 g / mL to obtain liquid A. Mix 12g of tobacco leaves (place of origin: Fujian) with 8g of tobacco powder sticks (produced by Longyan Cigarette Factory), add 1000g of water for leaching, the leaching temperature is 80°C, and the leaching time is 20min, filter to obtain the filtrate, and concentrate the filtrate to The density was 1.2g / mL, and liquid B was obtained. Mix liquid A and liquid B at a mass ratio of 1:1 to obtain a blank coating liquid.

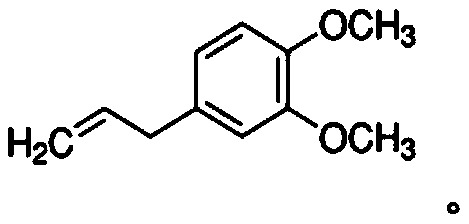

[0090] (2) Take 100 g of the blank coating solution, add 5.0 mg of eugenol methyl ether, and stir evenly to obtain coating solution 1.

Embodiment 2-5

[0092] Take multiple blank coating solutions, each 100g, add 1mg, 2.5mg, 7.5mg, 10mg of eugenol methyl ether respectively, and stir them evenly to obtain coating solutions 2-5. Wherein, the preparation method of the blank coating solution is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com