Table top type scribing machine

A scribing machine and mechanical technology, applied in shoemaking machinery, clothing, applications, etc., can solve the problems of many parts and troublesome adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

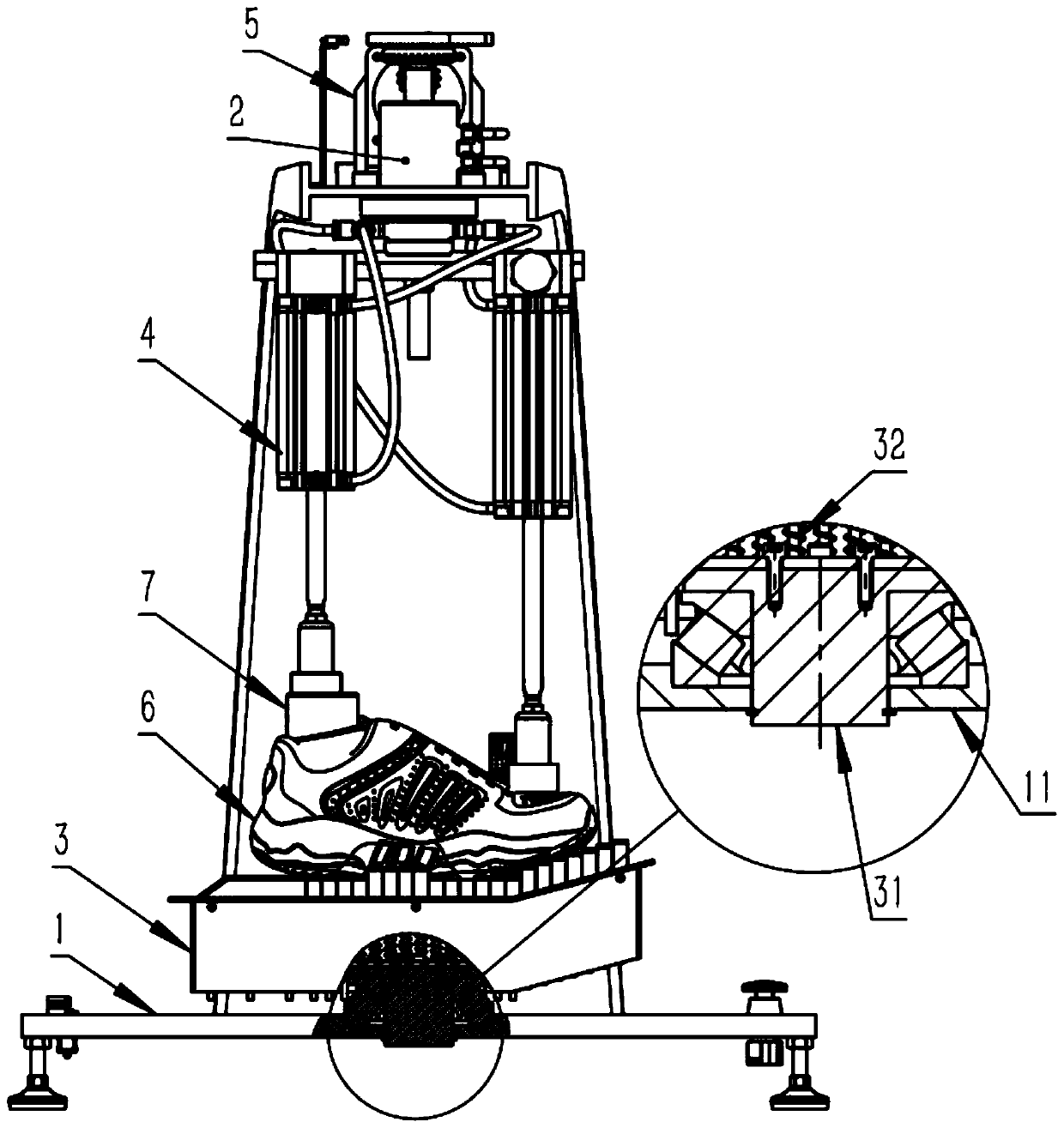

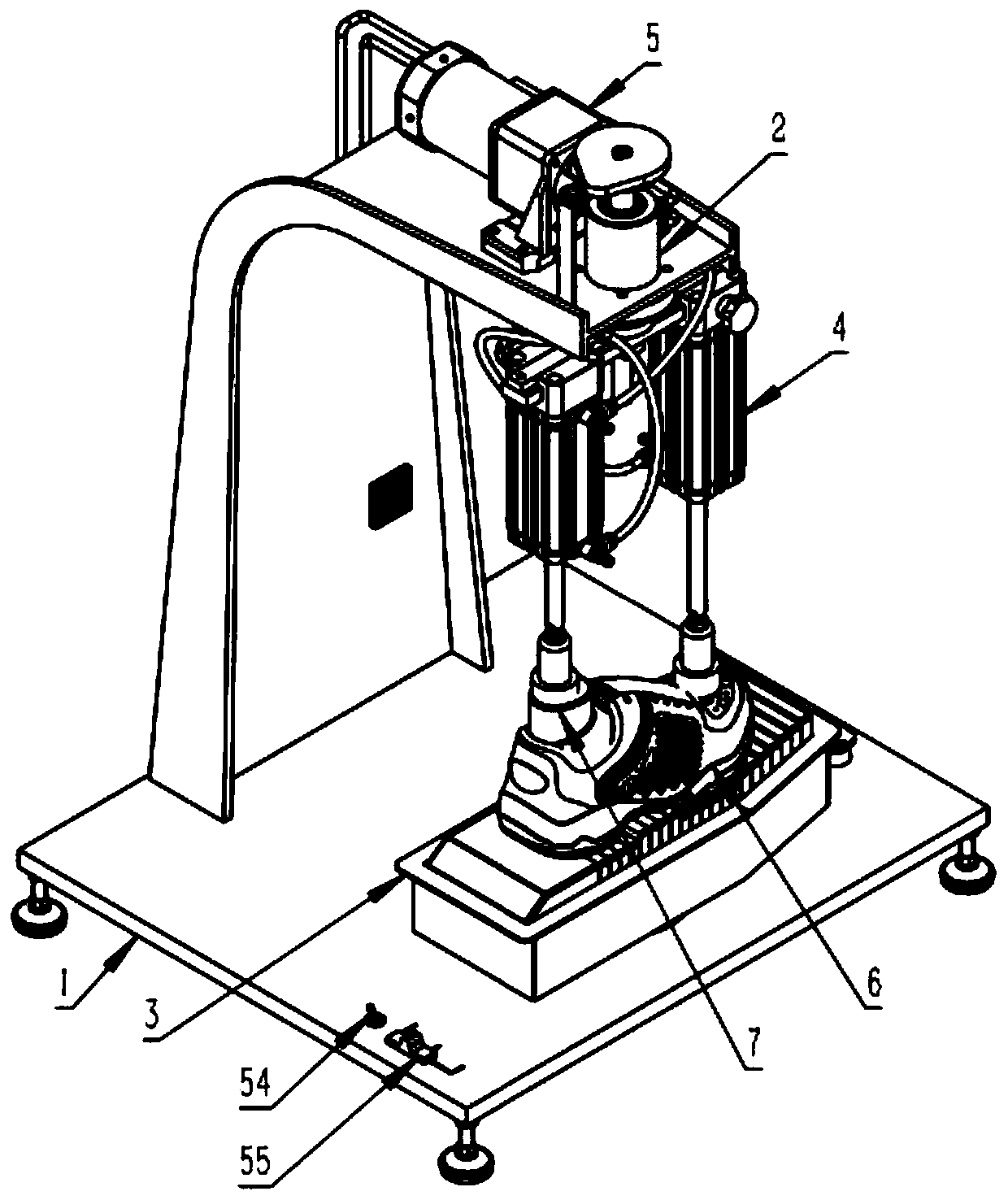

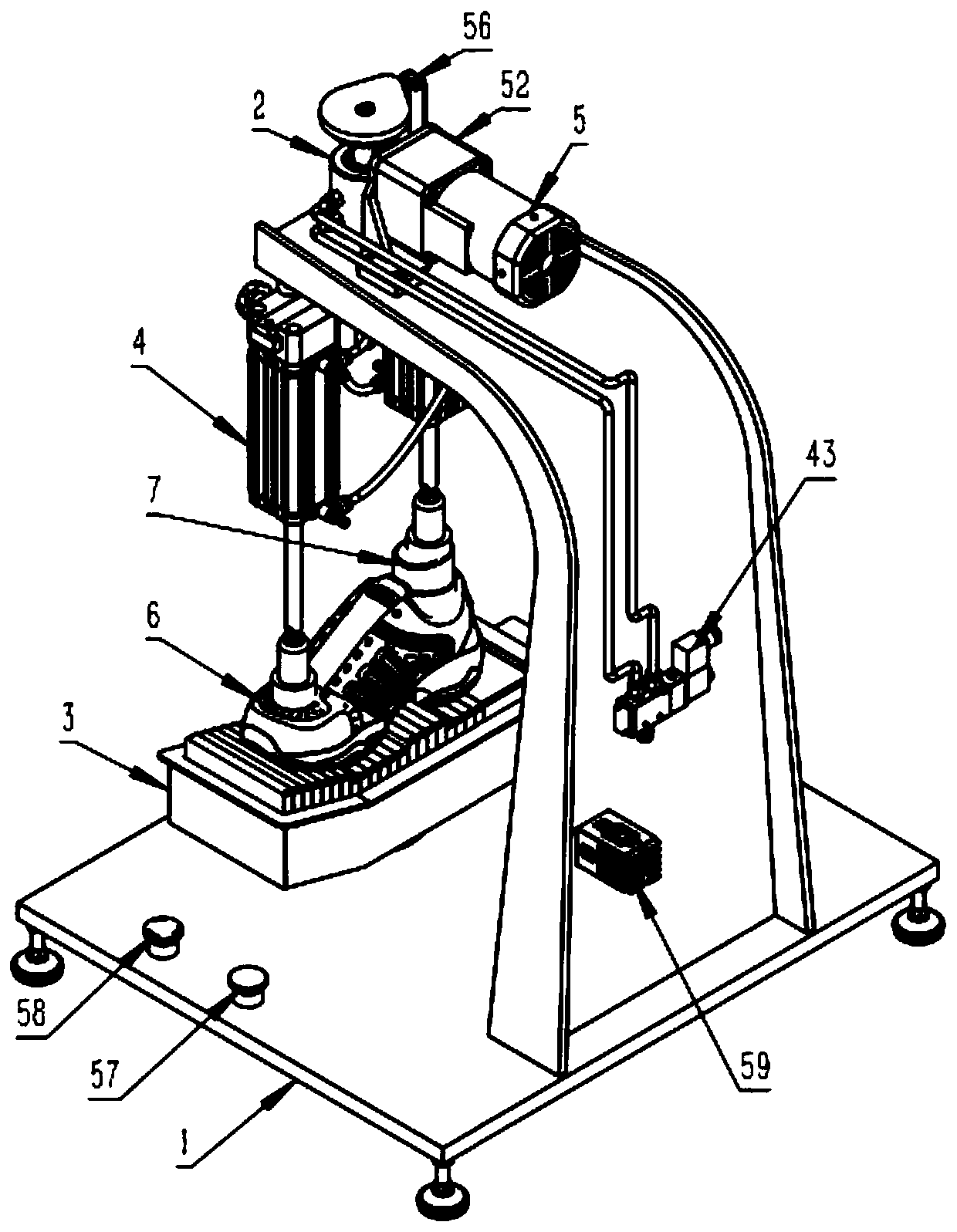

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

[0042] Such as Figure 8 , Figure 9 As shown, the mechanical frame 1 is processed first: the switch mounting hole 111, the governor mounting hole 112, the governor indicator 113, the motor switch mounting hole 114, the bearing mounting hole 117, and the foot cup threaded hole 118 are processed on the base 11; The bent neck is formed by bending a steel plate with a wide bottom and a narrow top by 90°, and the gas distribution rotary joint installation hole 115 and the time relay installation hole 116 are processed on the bent neck; the bent neck 12 and the rib plate 13 are welded on the base 11 ; Four foot cups 14 are installed on the base

[0043] Such as Figure 12 , Figure 13 As shown, the hole 211 is processed first, and the hole 211 includes the upper deep groove ball bearing hole 2111, the upper stepped hole 2112, the middle stepped hole 2113, the lower step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com