A laboratory extraction method for colloidal blending components used to prepare needle coke

An extraction method, laboratory technology, applied in the direction of solid solvent extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

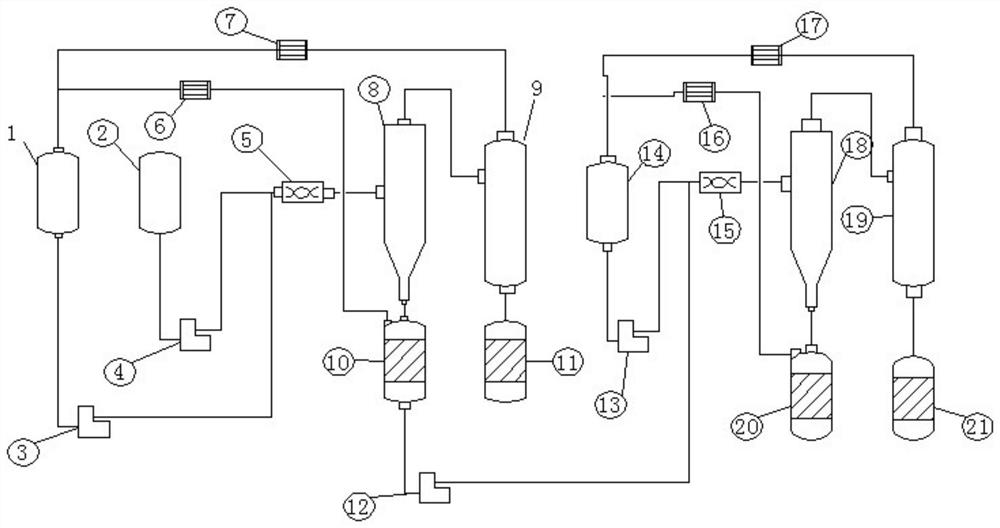

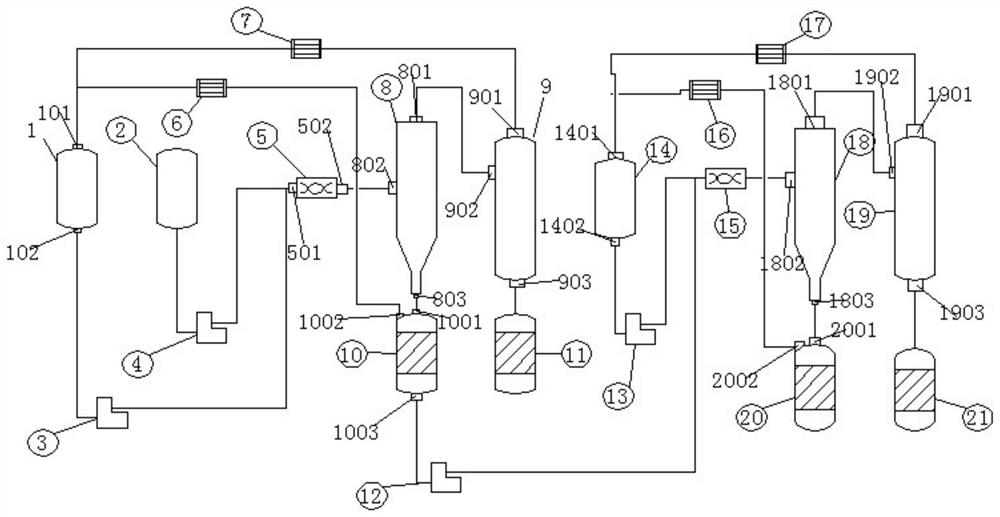

Method used

Image

Examples

Embodiment 1

[0060] A laboratory extraction method for preparing colloidal blending components of needle coke, comprising the following steps:

[0061] (1) After the raw material asphalt is temporarily stored in the raw material asphalt tank 2, it is sent to the raw material / solvent static mixer 5 through the raw material asphalt pump 4; sent to the raw material / solvent static mixer 5; the low-carbon aliphatic hydrocarbon and the raw material pitch are fully mixed in the raw material / solvent static mixer and then enter the supercritical extraction tower 8;

[0062] (2) In the supercritical extraction tower 8, the low-carbon aliphatic hydrocarbon performs supercritical extraction on the saturated and aromatic components in the raw asphalt, and the saturated and aromatic components in the raw asphalt are dissolved in the low-carbon aliphatic hydrocarbon solvent; the upper layer is dissolved The low-carbon aliphatic hydrocarbon solvent of saturated and aromatic content in the raw asphalt ente...

Embodiment 2

[0069] The present invention also provides a laboratory extraction method for preparing the colloidal blending component of needle coke, comprising the following refining steps:

[0070] (1) first add a certain amount of low-carbon aliphatic hydrocarbons into the low-carbon aliphatic hydrocarbon solvent tank 1 and the supercritical extraction tower 8; then add a certain amount of colloidal solvent into the colloidal solvent tank 14; then add a certain amount of The raw bitumen is added to the raw bitumen tank 2.

[0071] (2) After the raw asphalt is temporarily stored in the raw asphalt tank, turn on the low-carbon aliphatic hydrocarbon solvent pump 3 to inject the low-carbon aliphatic hydrocarbon into the raw material / solvent static mixer 5, and simultaneously open the raw asphalt pump 4 to inject the raw asphalt into the raw material / solvent static mixer 5. Mixer 5; the adding volume ratio of low-carbon aliphatic hydrocarbon and raw material pitch in the raw material / solvent...

Embodiment 3

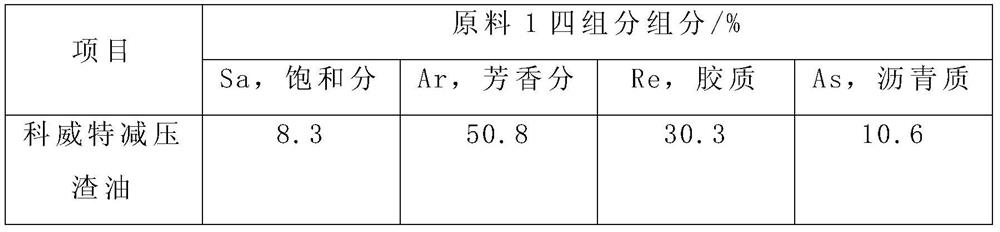

[0080] Embodiment 3: raw material bitumen selects Kuwait vacuum residue for use (the four components of raw material 1 are shown in Table 1); low-carbon aliphatic hydrocarbon selects propane; colloidal solvent selects tetrahydrofuran for use; the mixing volume ratio of propane and Kuwait vacuum residue is 4 : 1; the mixing volume ratio of tetrahydrofuran and supercritical raffinate is 3:1; the operating pressure of the supercritical extraction tower is 4.5MPa, and the operating temperature is 110℃; the operating pressure of the supercritical recovery tower is 1.5MPa, and the operating temperature is 110℃; The operating pressure of the residue collection tank is 1.5MPa, and the operating temperature is 110℃; the operating pressure of the gum extraction tower is 0.05MPa, and the operating temperature is 50℃; the operating pressure of the gum solvent recovery tower is 0.05MPa, and the operating temperature is 100℃; the operating pressure of the asphaltene collection tank is 0.05 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com