Reconstruction process of middle ore circulation mode based on copper-molybdenum potential control flotation separation

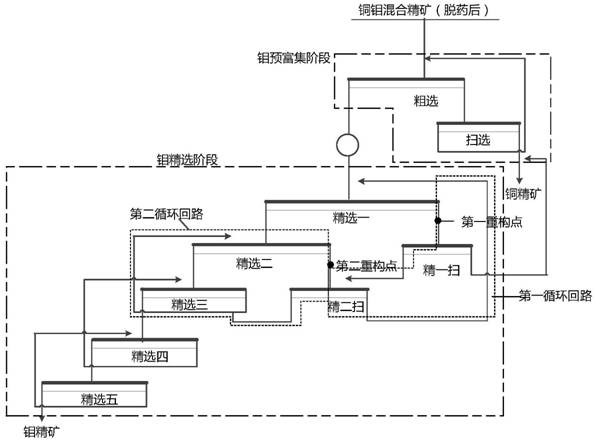

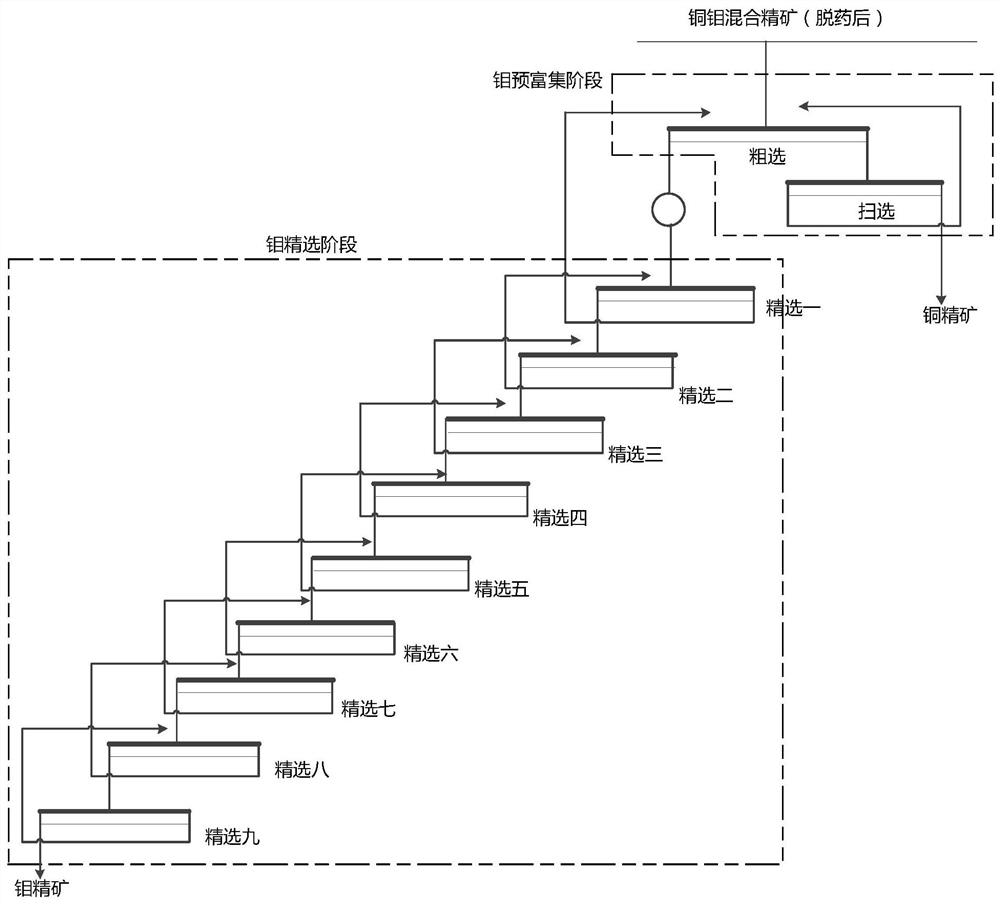

A potential control and circulation technology, applied in flotation, solid separation and other directions, can solve the problems of long separation process, difficult operation, large consumption of chemicals, etc., to shorten the selection process, reduce the amount of circulation, and improve the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

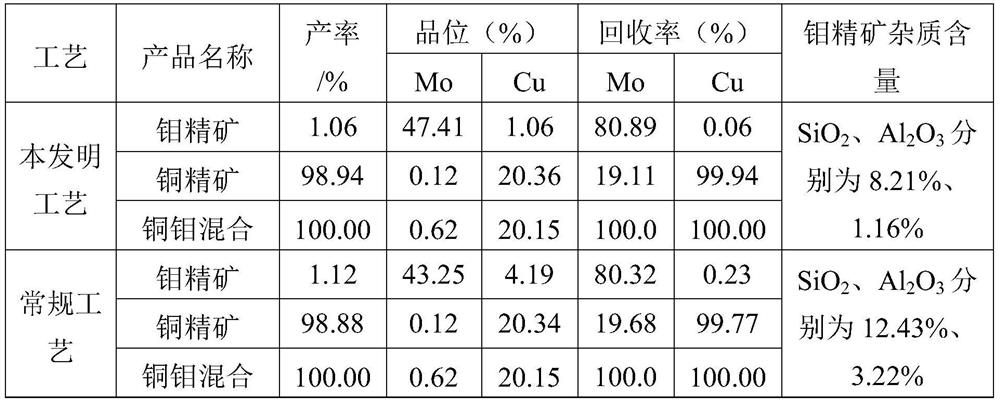

Embodiment 1

[0043] In a porphyry-type copper-molybdenum deposit in the Jungar area of Xinjiang, the molybdenum-containing minerals in the ore are mainly molybdenite, the copper is mainly chalcopyrite and bornite, and the gangue minerals are mainly mica, quartz and weathered feldspar. The molybdenum grade in the copper-molybdenum mixed concentrate after copper-molybdenum mixed flotation is 0.62%, and the copper grade is 20.15%.

[0044]After the main process of copper-molybdenum mixed flotation is to obtain the copper-molybdenum mixed concentrate for drug removal, the method of the present invention is used to go through one roughing and one sweeping to obtain molybdenum rough concentrate and copper concentrate, and the flotation concentration of roughing and sweeping is 22% and 20% respectively, the amount of roughing sodium sulfide is 18kg / t, the amount of sodium thioglycolate is 0.1kg / t, the roughing time is 6 minutes, the amount of sweeping sodium sulfide is 15kg / t, and the amount of ...

Embodiment 2

[0049] A porphyry-type copper-molybdenum deposit in the Narigongma area of Qinghai. The molybdenum-containing minerals in the ore are mainly molybdenite, the copper is mainly bornite and chalcopyrite, and the gangue minerals are mainly quartz, mica, and weathered feldspar. After copper-molybdenum mixed flotation, the molybdenum grade in the copper-molybdenum mixed concentrate is 0.62%, and the copper grade is 20.15%.

[0050] After the main process of copper-molybdenum mixed flotation is to obtain the copper-molybdenum mixed concentrate for drug removal, the method of the present invention is used to go through one roughing and one sweeping to obtain molybdenum rough concentrate and copper concentrate, and the flotation concentration of roughing and sweeping is 25% and 23% respectively, the amount of roughing sodium sulfide is 28kg / t, the amount of sodium thioglycolate is 0.2kg / t, the roughing time is 7 minutes, the amount of sweeping sodium sulfide is 25kg / t, and the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com