Ultra-fast seven-axis five-linkage laser processing system

An ultra-fast laser and processing system technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve efficient processing of complex spatial contours, guaranteed processing quality, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Attached below Figure 1-9 The present invention will be described in detail. The following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

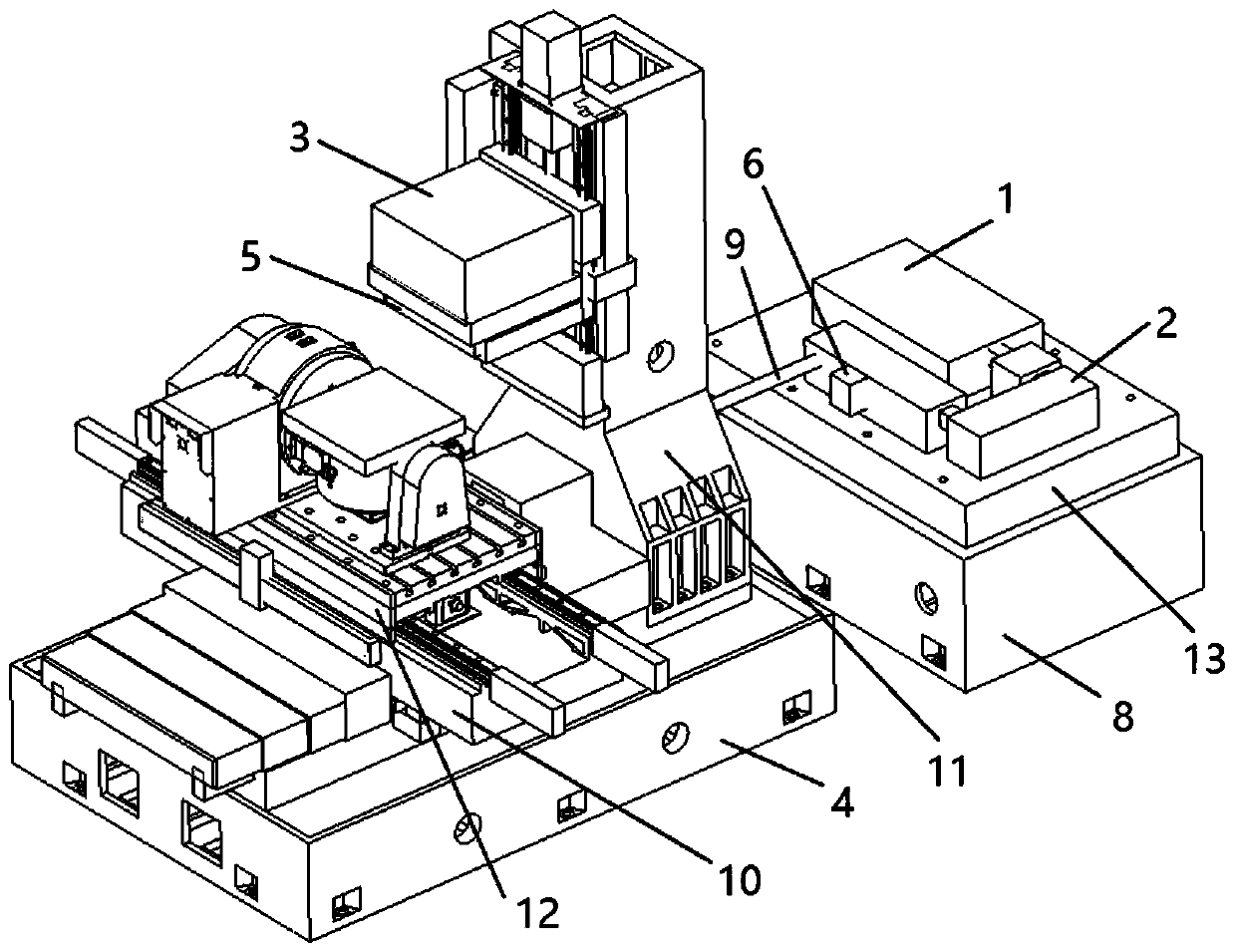

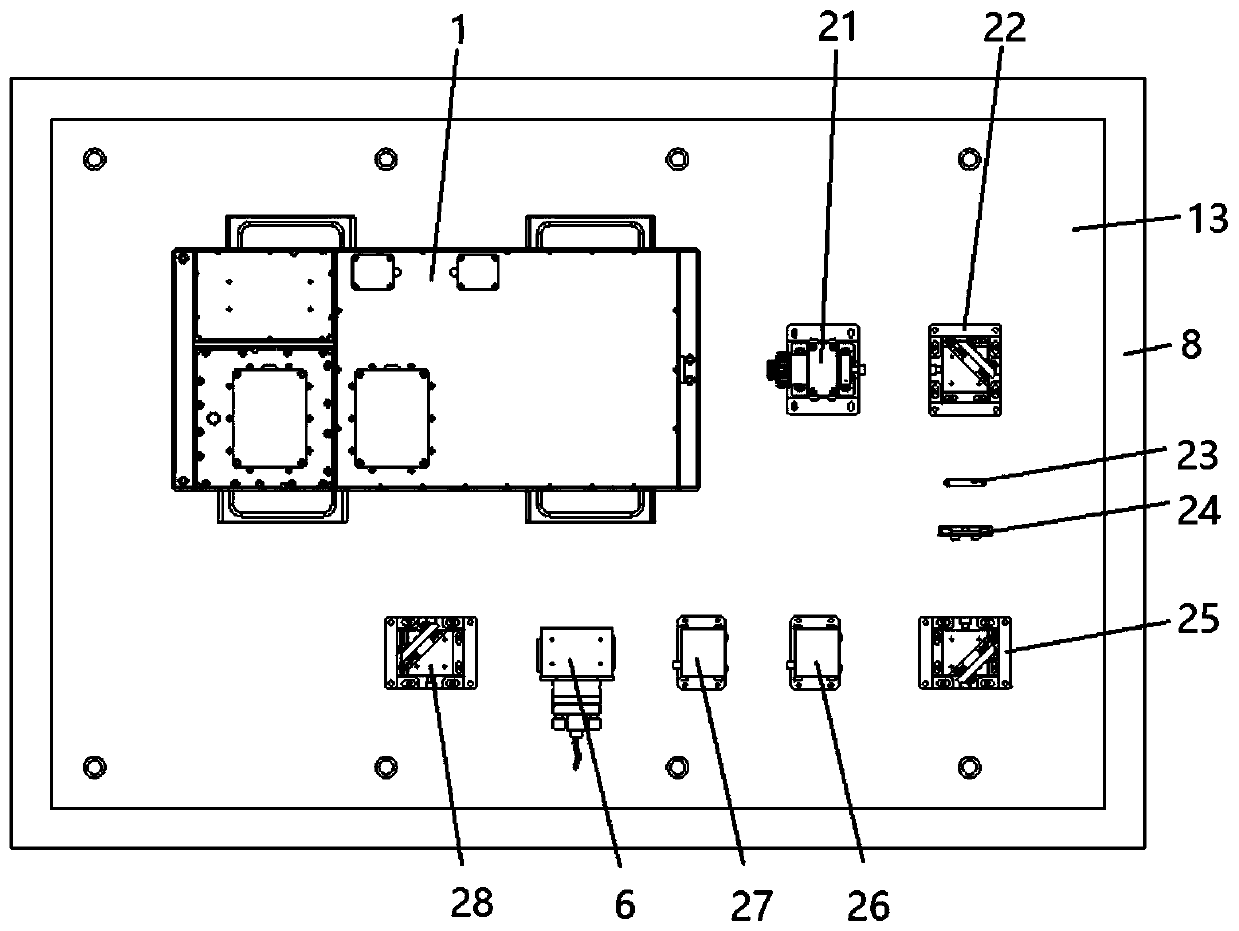

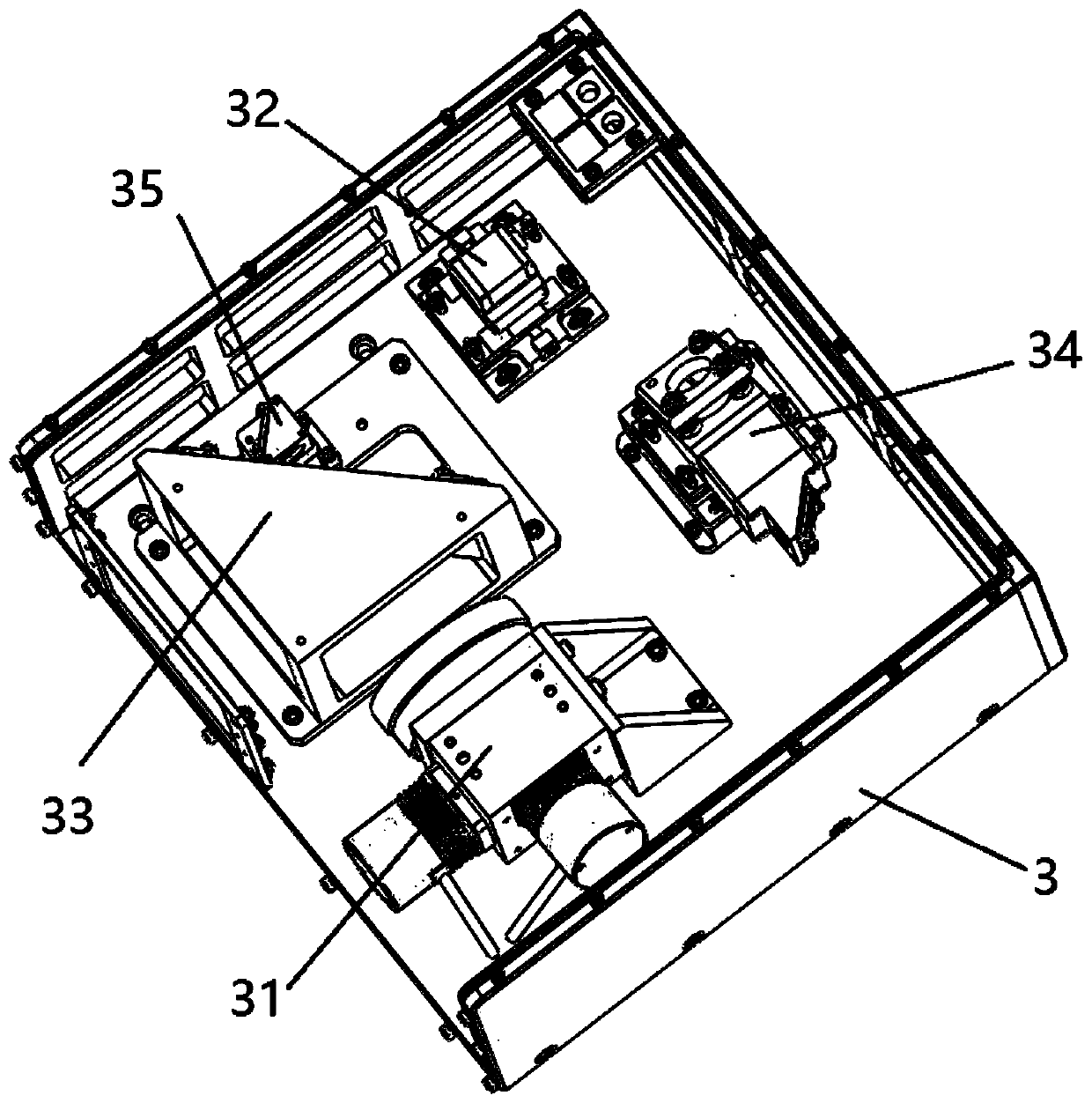

[0056] Such as Figure 1 to Figure 9 As shown, a seven-axis five-linkage ultrafast laser processing system provided by the present invention includes a laser light source 1 installed on a marble base 13, which is installed on the base 8; and a beam transmission system 2, The beam transmission system 2 is installed on the marble base 13 and includes a first reflector 22, a second reflector 25, a third reflector 28, a beam expander 21, a quarter wave plate 23, a shutter 24, and an optical bracket 26 And the optical bracket 27, in which the first mirror 22, the second mirror 25 and the third mirror 28 are used to reflect the light generated by the laser to the sixth mirror 1111, and to the processing head 3 through the sixth mirror 1111, The sixth reflector 1111 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com