Electric vehicle coupling heat management system with high safety

A technology for electric vehicles and management systems, applied in electric vehicles, circuits, electrical components, etc., can solve the problems of low safety, easily damaged batteries, and inability to quickly and normally use the temperature, and achieve the effect of quickly adjusting the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

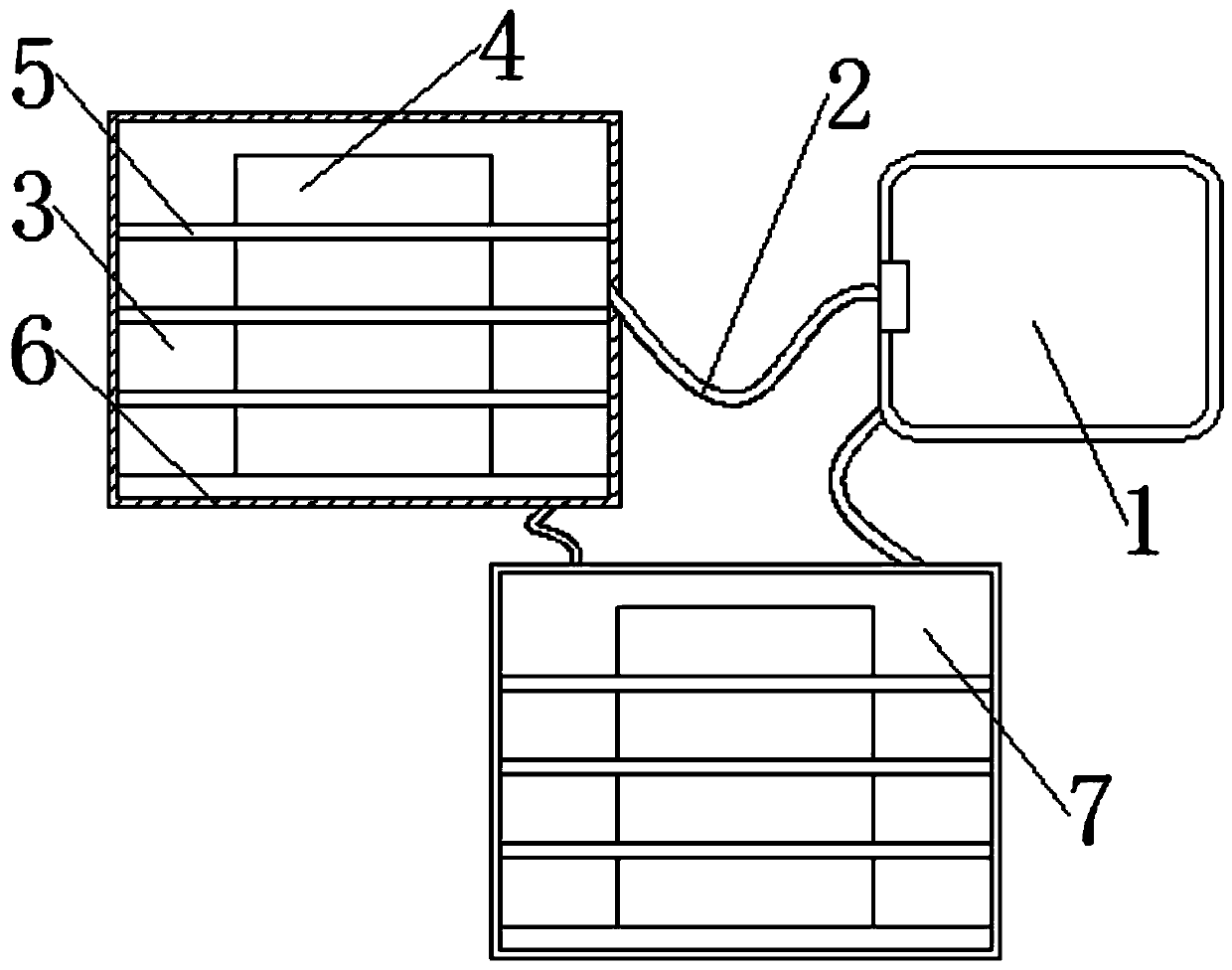

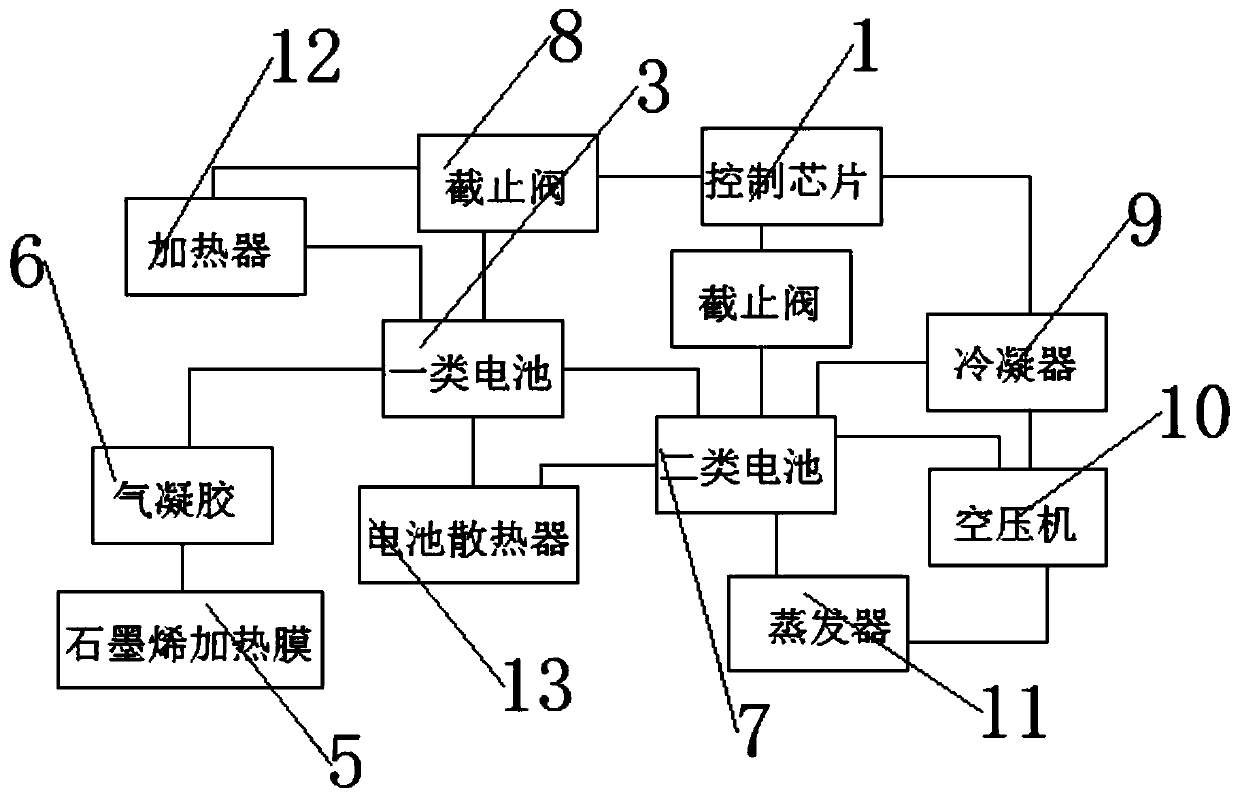

[0025] see figure 1 to attach figure 2 , a high-safety electric vehicle coupling thermal management system, mainly using control chip 1, wire 2, first-class battery 3, battery cell 4, second-class battery 7, stop valve 8, condenser 9, air compressor 10, The combination of evaporator 11, heater 12 and battery radiator 13 forms a high-safety electric vehicle coupling thermal management system;

[0026] The control chip 1 is electrically connected to the first-class battery 3, the second-class battery 7, the condenser 9, the air compressor 10, the evaporator 11, the heater 12, and the battery radiator 13 through electric wires 2, and the first-class battery 3 Airgel 6 is wrapped with screws on the outside, and cells 4 are installed inside the first-class battery 3 and second-class battery 3 .

Embodiment 2

[0028] A graphene heating film 5 is installed on one side of the internal cell 4 of the first-class battery 3, and a battery radiator 13 is installed on one side of the first-class battery 3 and the second-class battery 7, and a battery radiator 13 is installed on one side of the first-class battery 3. Heater 12, and the internal temperature of the first type battery 3 is 25-35°C, one side of the second type battery 7 is equipped with an evaporator 11, an air compressor 10 and a condenser 9 through the wire 2, and the internal temperature of the second type battery 7 is -10-2°C, and the first-class battery 3 and the second-class battery 7 are electrically connected through the wire 2, and the control chip 1 quickly controls the first-class battery 3, the condenser 9, the air compressor 10, and the evaporator through the cut-off valve 7 11. The heater 12 and the battery radiator 13, and the condenser 9 and the air compressor 10 are connected to the cockpit air-conditioning throu...

Embodiment 3

[0030] First, install this system. When the temperature of the electric vehicle is low, the control chip will open the first battery through the cut-off valve, the first battery will generate current, and the first battery will maintain the internal temperature of the first battery at 25-35°C through the heater. , then a type of battery drives the car through the electric drive system, and the graphene heating film wraps one side of the cell, which makes the heat transfer efficiency of the cell higher, and makes the heating effect of the type of battery relatively better, and makes the interior of the electric vehicle heat up quickly , when the temperature of the electric vehicle is high, the control chip will turn off the first battery and the heater through the cut-off valve, and turn on the second battery, and the second battery will keep the internal temperature at -10 through the condenser, air compressor and evaporator -2°C, which makes the interior of the electric vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com