Nano water-repellent down production process

A production process and down technology, applied in the field of down production, can solve the problems of the reduction of nanomaterials and the decline of the hydrophobicity of down, and achieve the effects of improving adsorption, tight adsorption and improving cleanliness.

Active Publication Date: 2019-06-28

浙江茂龙家纺有限公司

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, after the eiderdown is stirred and mixed with the aqueous solution of nanomaterials, it needs to be rinsed several times, so that the attached nanomaterials on the eiderdown are reduced, and the hydrophobicity of the eiderdown is reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0057] The difference between Examples 10-13 and Example 1 is that the parts by weight of the components in the dispersant are listed in the table below.

[0058]

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

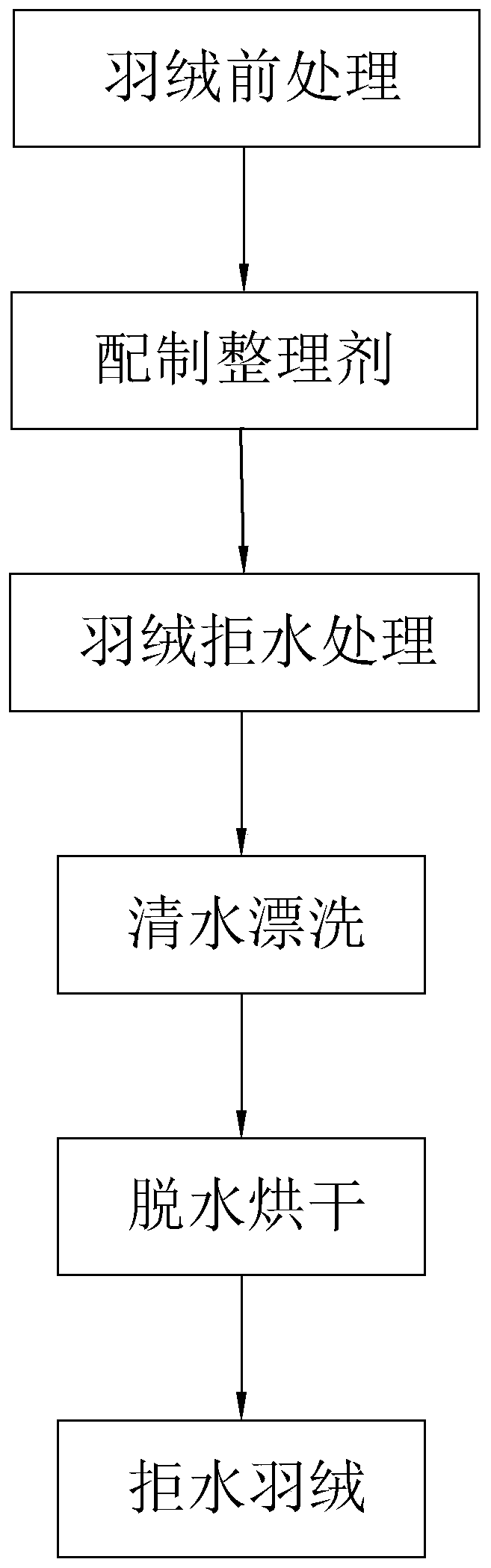

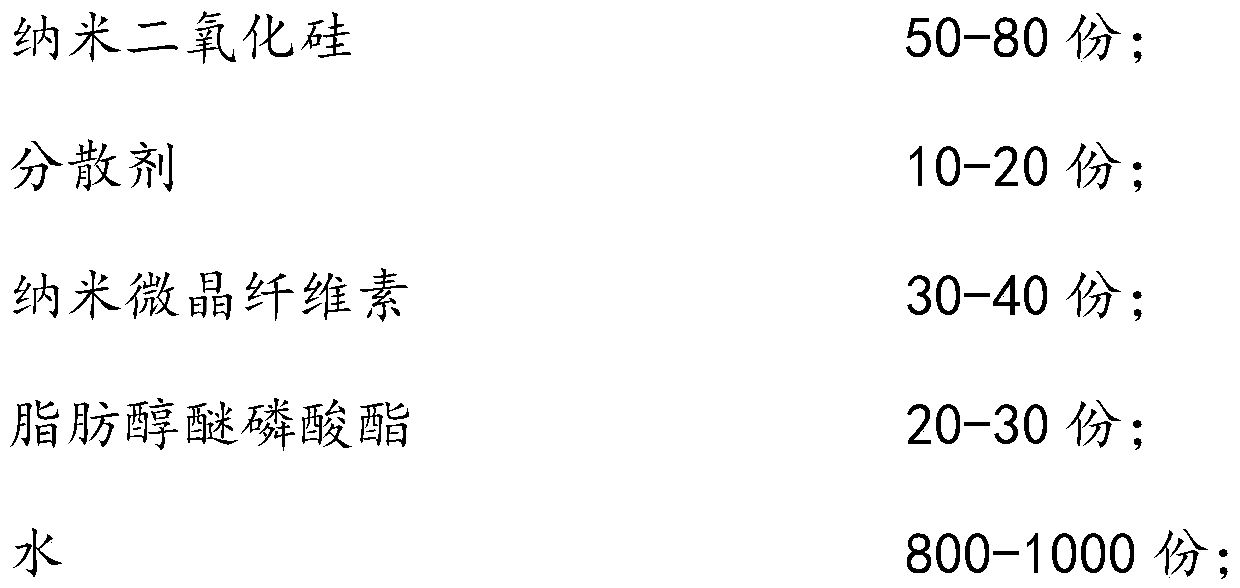

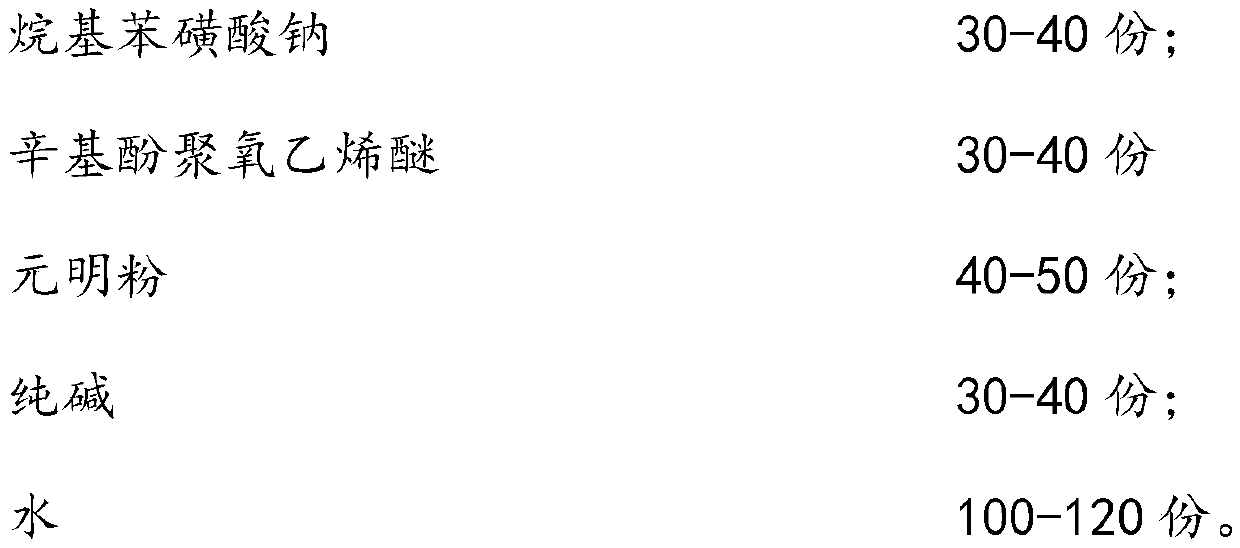

The invention discloses a nano water-repellent down production process, and relates to the technical field of down production. The process comprises the following steps that S1, a down material is immersed in a pre-treatment liquid for pre-treatment at first; S2, a finishing agent is prepared, wherein the finishing agent is prepared from, by weight, 50-80 parts of nano silica, 10-20 parts of a dispersant, 30-40 parts of nano microcrystalline cellulose, 20-30 parts of fatty alcohol ether phosphate and 800-1,000 parts of water; S3, the down is added into a washing stirrer at first, and then water and the finishing agent are added for stirring and mixing; S4, the stirred down is rinsed with clear water 10 times; S5, the rinsed down is spin-dried and dewatered; S6, the dewatered down is put into a drying box for stirring and drying. The process has the advantage that the adhesion tightness of the nano silica and the nano microcrystalline cellulose to the surface of the down is improved.

Description

technical field [0001] The invention relates to the technical field of down production, in particular to a production process for nano water-repellent down. Background technique [0002] Down is a kind of animal protein fiber. There are tens of thousands of small triangular pores densely covered in the down ball-shaped fiber, which can shrink and expand with temperature changes, and has the function of temperature regulation. It can absorb the flowing heat from the human body and isolate the invasion of cold air from the outside. However, when the down encounters water, the water adheres to the fibers, reducing the pores between the fibers and shrinking the down, thereby greatly reducing the heat preservation and temperature regulation effect of the down. [0003] At present, the technology of applying nanometer water-repellent materials to the surface of down fibers enables down to obtain better water-repellent performance, and has solved the defect that down has a reduced ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06M19/00

Inventor 袁福林

Owner 浙江茂龙家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com