Gypsum cutting device for orthopedic treatment

A cutting device and gypsum technology, applied in medical science, stone processing tools, stone processing equipment, etc., can solve problems such as movement, cutting knife contact, skin injury, etc., and achieve the effect of reducing the probability of rotation and tight adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

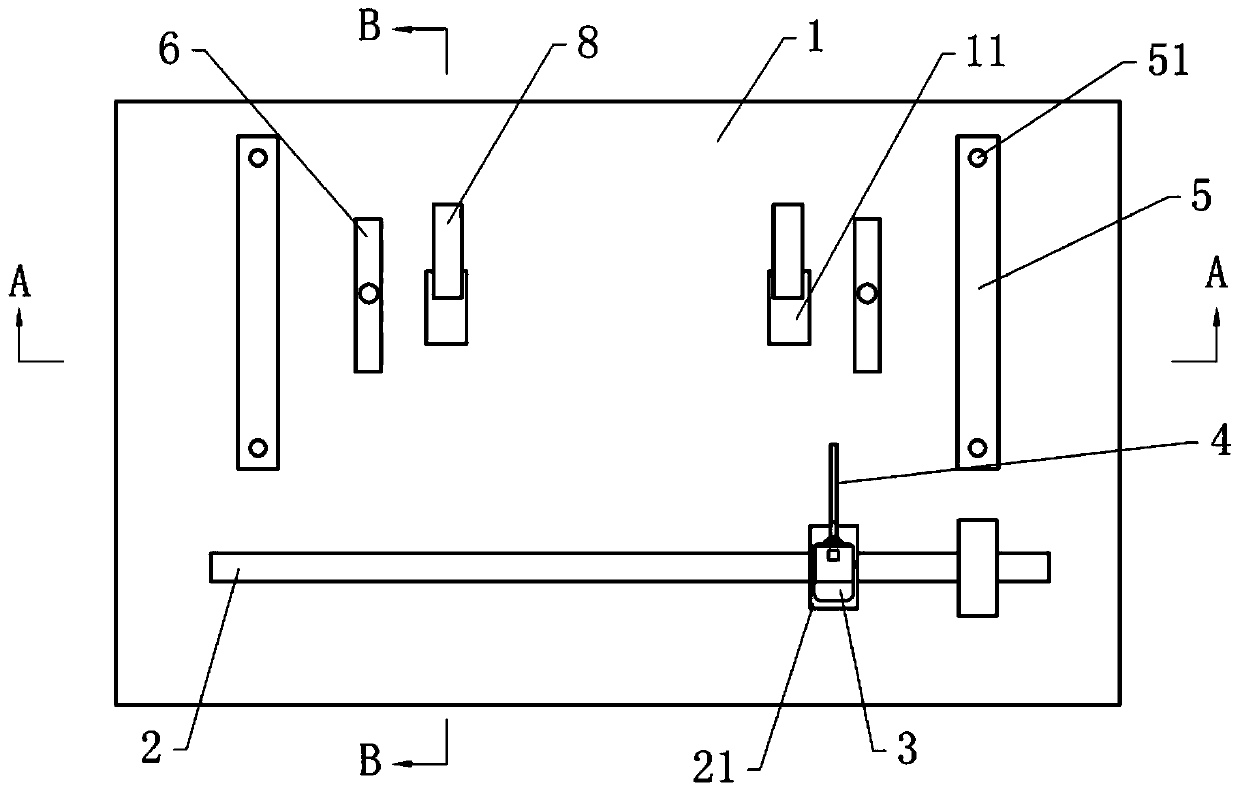

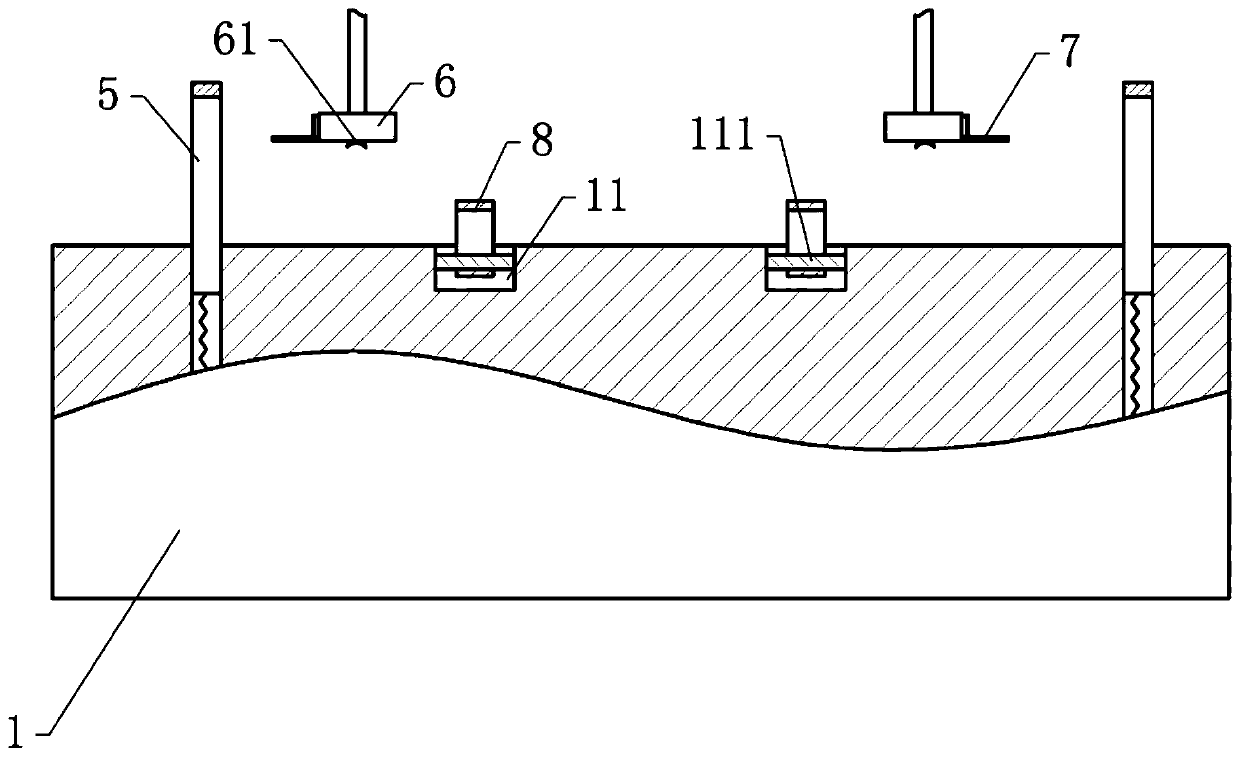

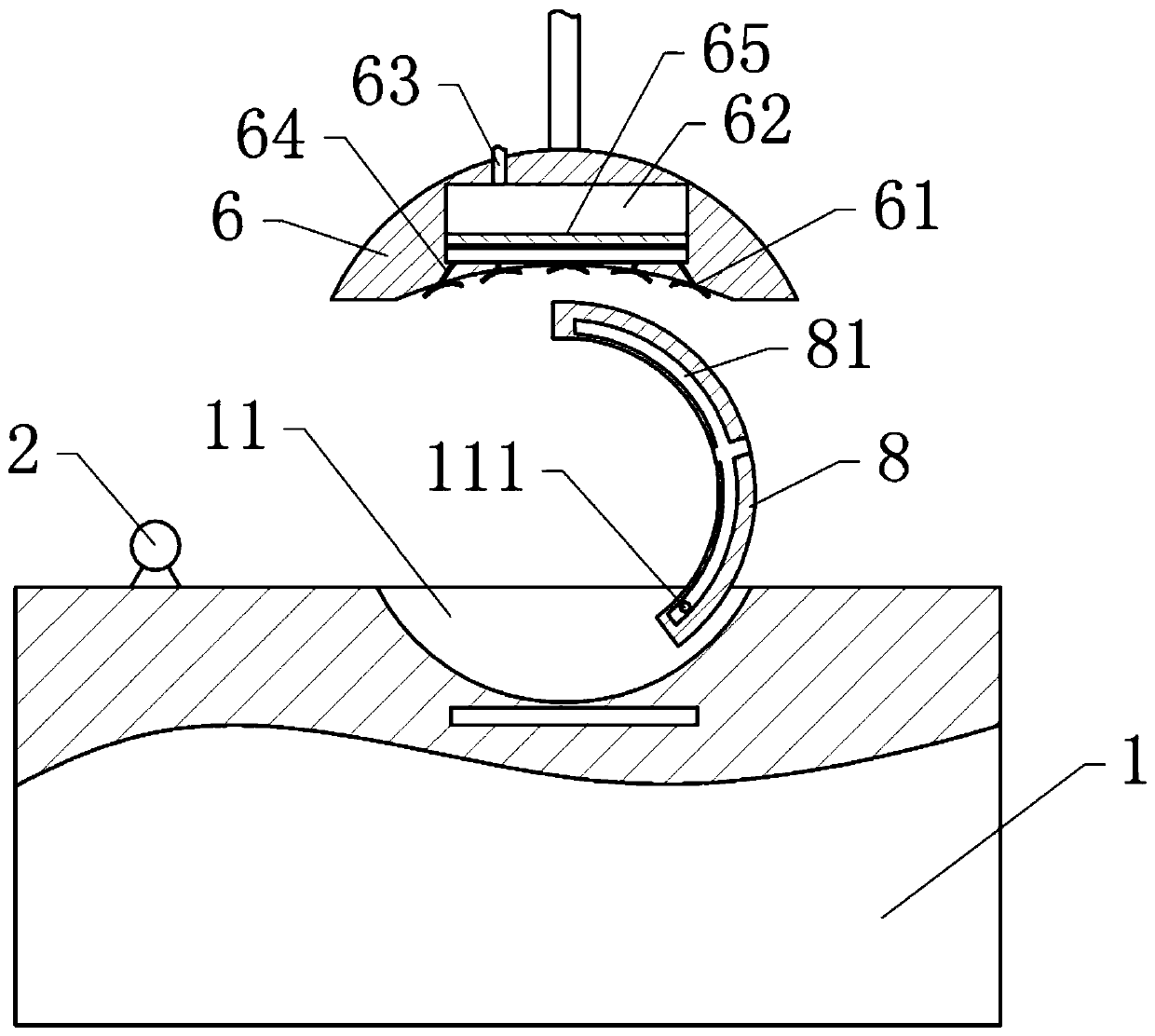

[0036] A plaster cutting device for orthopedic treatment, basically as attached figure 1 , figure 2 As shown, it includes workbench 1, which is provided with a horizontal chute, and a ball screw 2 is arranged in the chute, and a slider 21 is fixed on the ball screw 2. When the ball screw 2 starts, it can realize The slider 21 slides reciprocally laterally. The upper surface of the slide block 21 is provided with a vertical groove (i.e. a groove perpendicular to the chute), and a motor 3 is slidably connected in the vertical groove, and the output shaft of the motor 3 is provided with a cutting knife 4. The slider 21 is also fixed with an infrared detector and a controller that controls the sliding of the cutting knife 4 along the slider 21. The infrared detector can detect the thickness of the plaster and transmit the signal to the controller, so that the controller controls the sliding of the cutting knife 4 , realizing the real-time adjustment of the position of the cutti...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is only that, as Figure 4 , Figure 5 As shown, the left end of the arc-shaped block 8 is provided with an arc-shaped hole 82 concentric with it, and an arc-shaped sliding block 83 is slidably connected in the arc-shaped hole 82, and the opening end of the arc-shaped hole 82 in the sliding block 83 is provided with a limit block 84 One end of the sliding block 83 located in the arc-shaped hole 82 is provided with a protrusion 85 . The pressing block 6 is located above the arc block 8 .

[0047] The specific implementation process is as follows: when the arc block 8 is fixed, the slide block 83 is partly slid out of the arc hole 82, and when the pressing block 6 moves down, it contacts with the slide block 83. The surface should be smooth, so that the suction cup 61 can be fixed more tightly. After the gypsum is cut twice, the separation effect is better, and the compression effect is also better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com