Post-cast belt supporting-free structure and post-cast belt construction method

A technology for supporting structures and post-casting belts, which is used in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of inability to clean up debris in post-casting belts, waste of materials, time-consuming and labor-intensive, and avoid secondary erection. The process of the support frame, the effect of improving the construction efficiency and the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

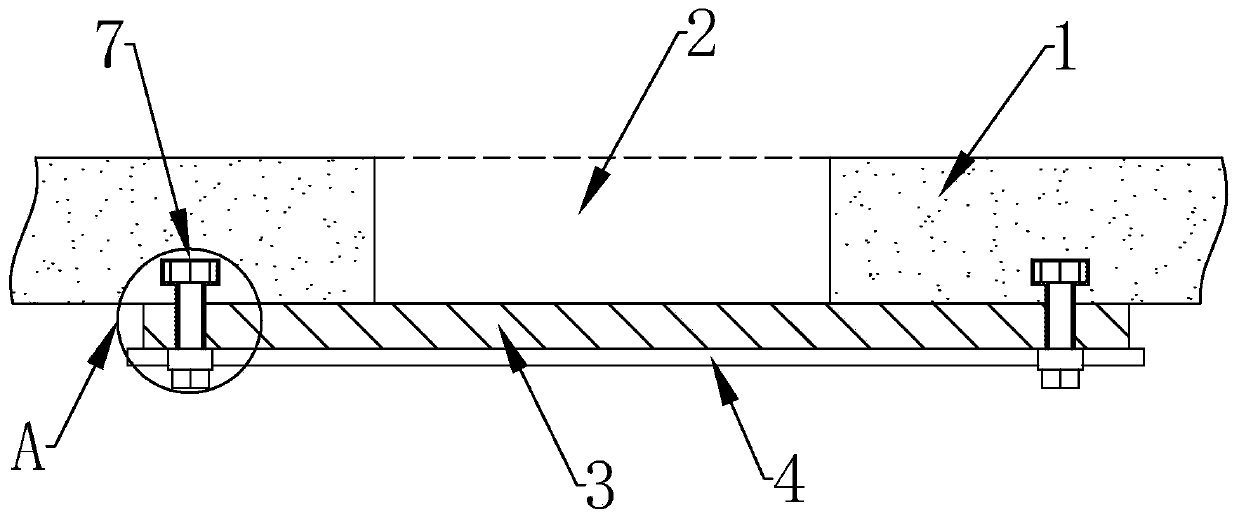

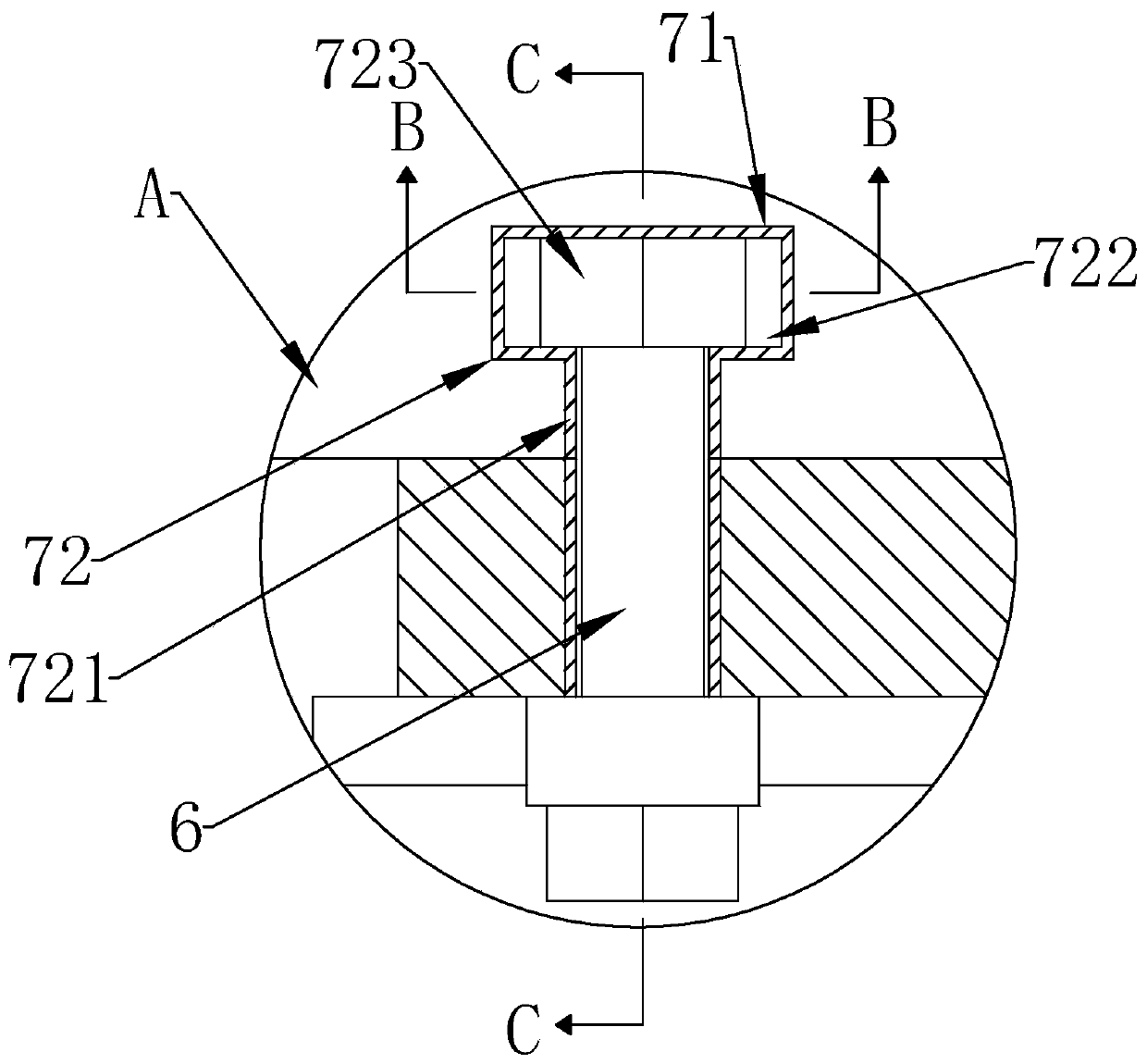

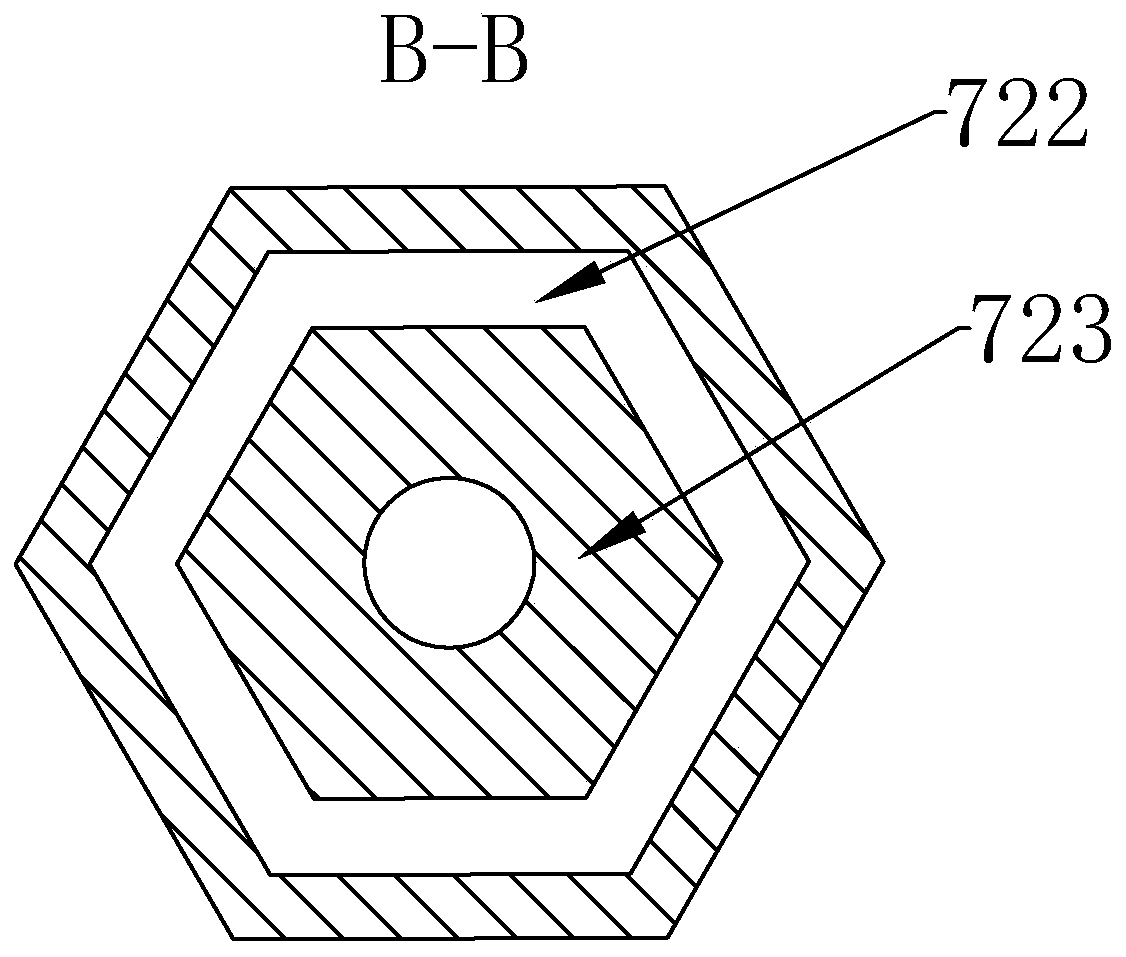

[0026] Please combine Figure 1 to Figure 4 , shows a support-free structure with post-casting belt 2, including a pre-cast concrete layer 1, a post-casting belt 2, a bottom formwork 3, a load-bearing steel pipe 4, a mountain-shaped card 5 and bolts 6, and the bottom formwork 3 is pre-embedded The parts 7 and the bolts 6 are installed and fixed under the first poured concrete layer 1, and poured between the two sections of the first poured concrete layer 1 to form the post-cast belt 2. Specifically, the embedded parts are set in the two sections of the first poured concrete layer 1 7. Correspondingly, through holes 31 matching the embedded parts 7 are provided at both ends of the bottom formwork 3. In order to enhance the bearing stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com