Method for manufacturing cathode of display panel, display panel and display device

A manufacturing method and display panel technology, applied in the field of OLED panels, can solve problems such as light-emitting layer damage, and achieve the effect of preventing physical damage and bombardment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention provide a method for manufacturing a cathode of a display panel, a display panel and a display device, so as to solve the technical problem existing in the prior art that the light-emitting layer is damaged when a sputtering process is used to manufacture a transparent cathode.

[0049] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

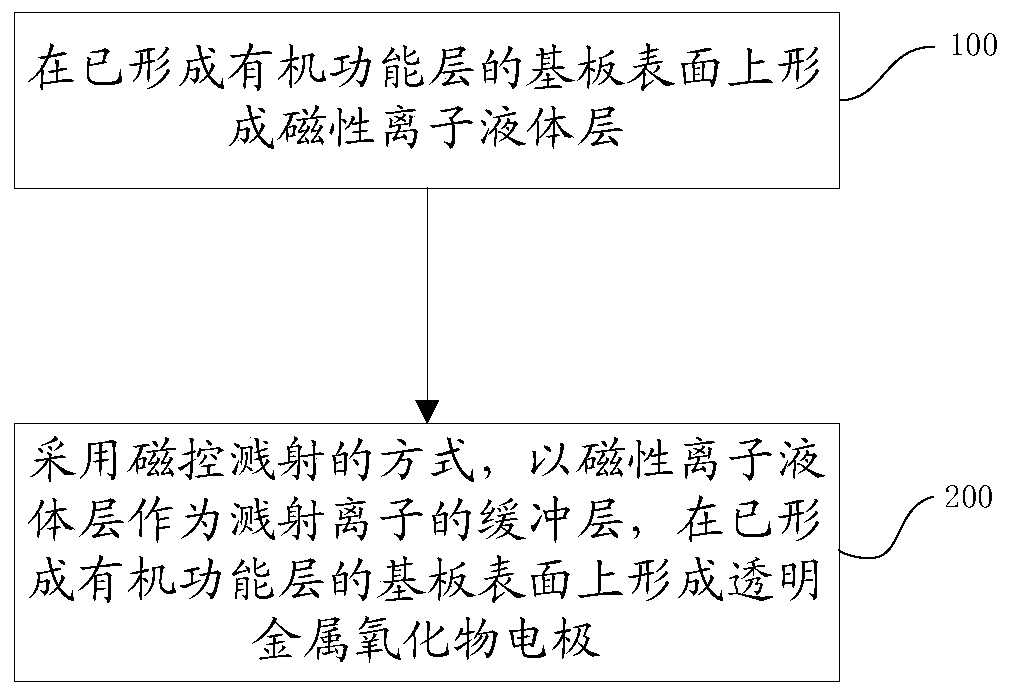

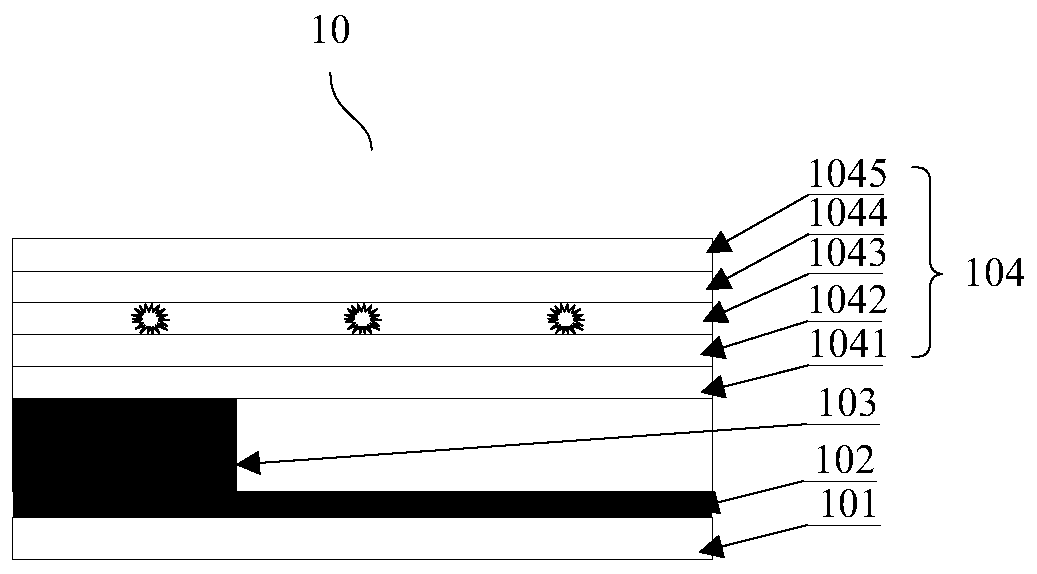

[0050] A method for manufacturing a cathode of a display panel is provided, comprising: forming a magnetic ionic liquid layer on the surface of a substrate on which an organic functional layer has been formed; adopting magnetron sputtering, using the magnetic ionic liquid layer as a buffer layer for sputtering ions, A transparent metal oxide electrode is formed on the surface of the substrate on which the organic functional layer has been formed.

[0051] In the above scheme, after forming the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com