Automatic batching system for iron ore material

An automatic batching and stone technology, applied in mixer accessories, dissolving, mixers, etc., can solve problems such as large differences in particle size, chemical composition, moisture, inability to accurately guide on-site batching goals, and uncertainty in test results. Reduced sticking and smooth running, high specific gravity, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

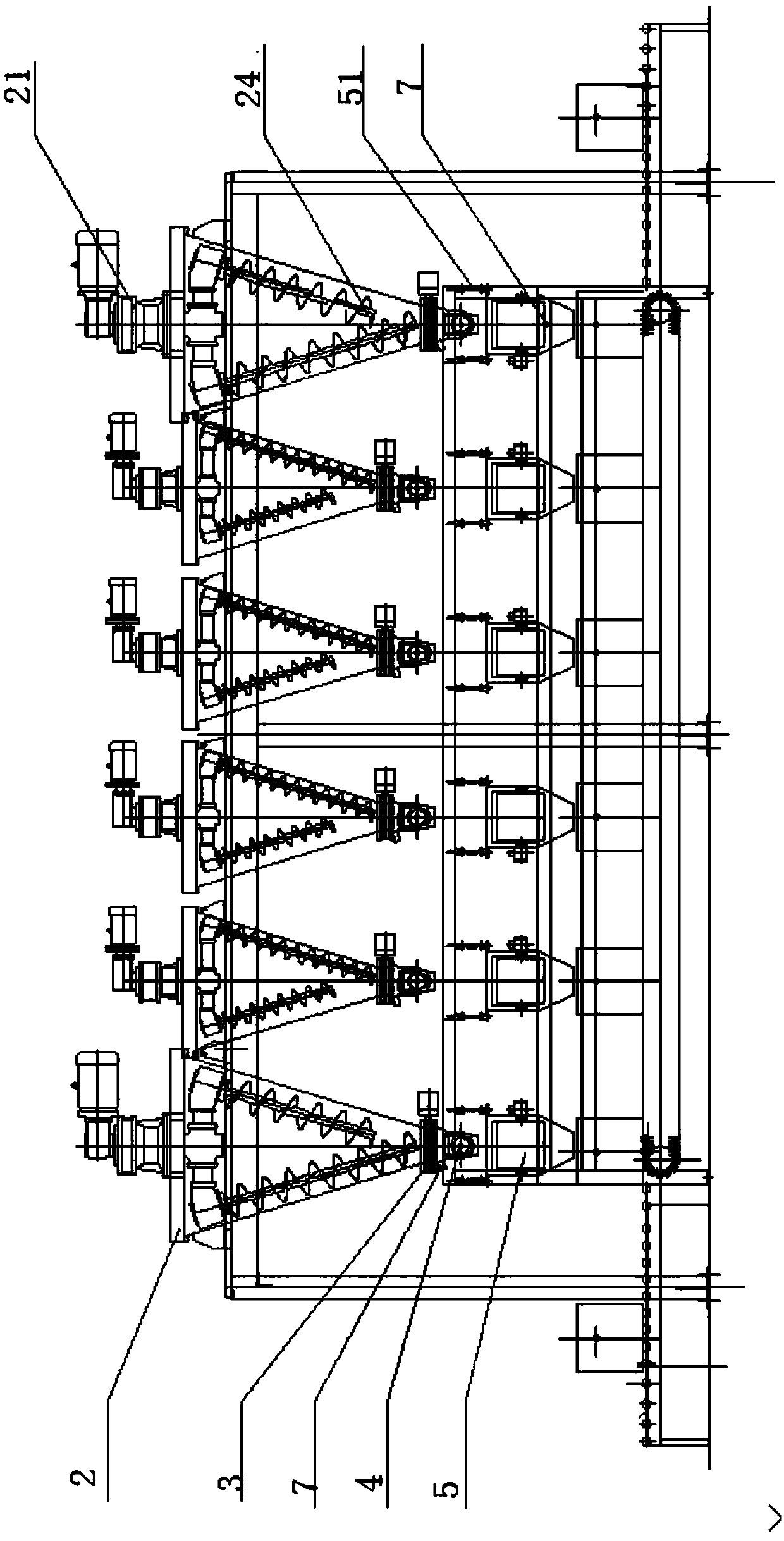

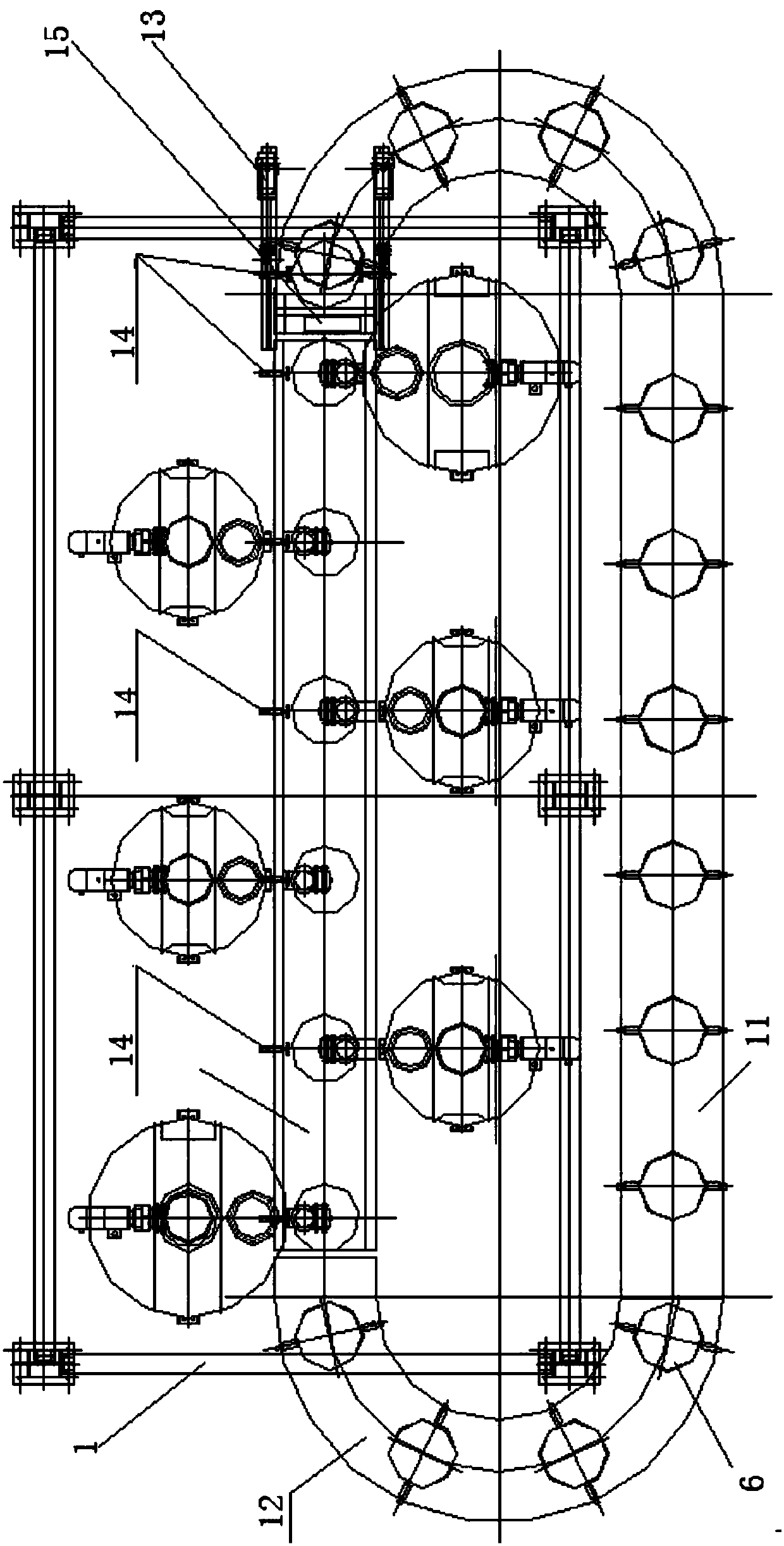

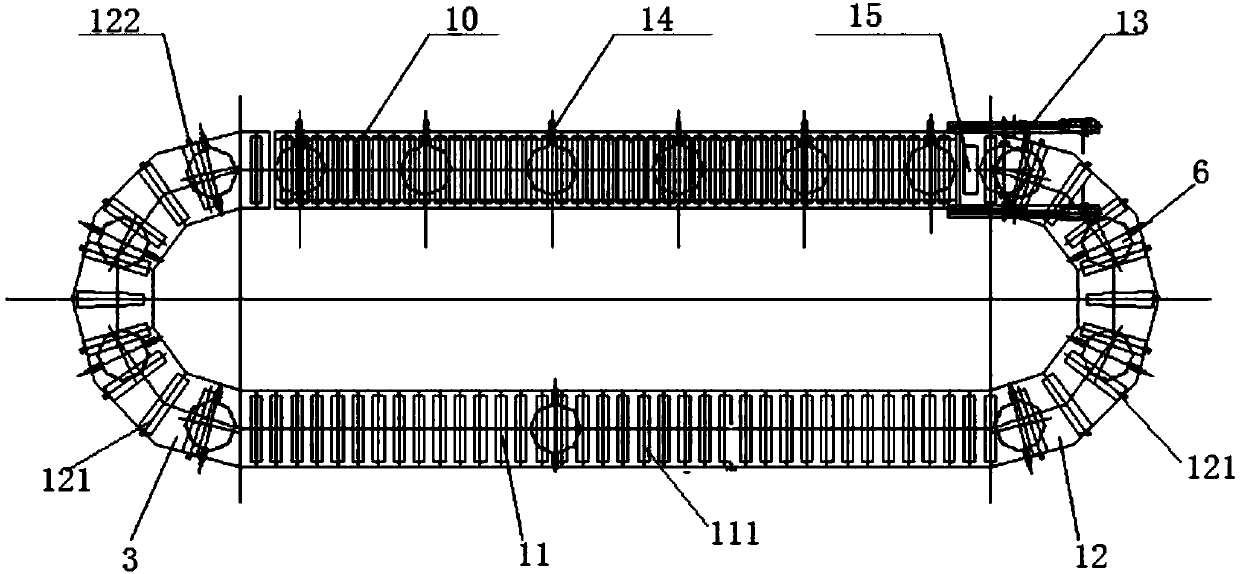

[0033] Embodiment 1: see Figure 1-Figure 8 , an automatic batching system for iron ore materials, the automatic batching system for iron ore materials includes a support frame 1, a computer control system, a stocker, an automatic mixing and weighing device, and an automatic positioning and identification transportation device, the automatic mixing and weighing device The measuring device is arranged on the support frame, wherein the automatic positioning and identification transportation device is located under the automatic mixing and weighing device, and the computer control system controls the entire batching system; the automatic mixing and weighing device includes a double-screw mixer 2, a pneumatic Plate valve 3, screw feeder 4, tiltable electronic scale 5 and control system, the double-screw mixer is fixed on the support frame 2, the bottom of the double-screw mixer is connected to the material receiving port of the screw feeder The pneumatic flapper valve 3 is connect...

Embodiment 2

[0034] Example 2: see Figure 1-Figure 4 , as an improvement of the present invention, the pourable electronic scale includes a controller, a limit switch, a weighing sensor 52, a scale frame 52, a dumping device 53 and a weighing bucket 54, and one end of the weighing sensor 51 is connected to a scale Frame 52, the other end is connected on the support frame 1, and the described dumping device is connected with the weighing bucket and is fixed on the weighing frame, and the limit switch is set on the dumping device to control the tilting angle of the dumping device, and the control system is based on the load of the weighing bucket. Adjust the screw feeder by adjusting the difference between the amount of material and the set value, and automatically adjust the amount of material received by the weighing hopper by controlling the speed of the feeder until the amount of material received is the same as the set value. The device is dumped, and the automatic mixing and weighing ...

Embodiment 3

[0035] Embodiment 3: see Figure 1-Figure 5 , as an improvement of the present invention, the connecting pipe between the pneumatic slide valve 3 and the screw feeder 4 is provided with a first pneumatic vibration cleaning device 7 to avoid material blockage, and the first pneumatic vibration The clearing device is a high-frequency pneumatic vibrating clearing device, the weighing hopper is provided with a second pneumatic vibrating clearing device 8, and the second pneumatic vibrating clearing device 8 is a percussion type pneumatic vibrating Cleaning device to avoid material sticking. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com