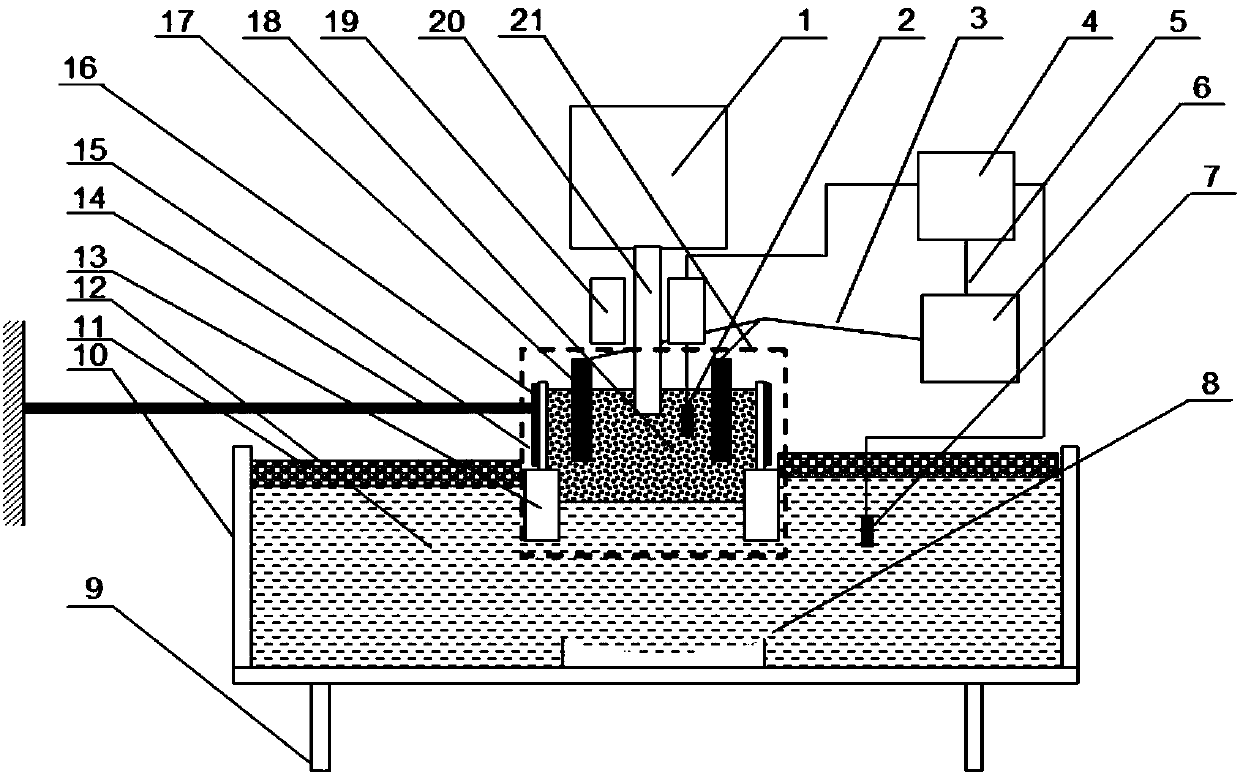

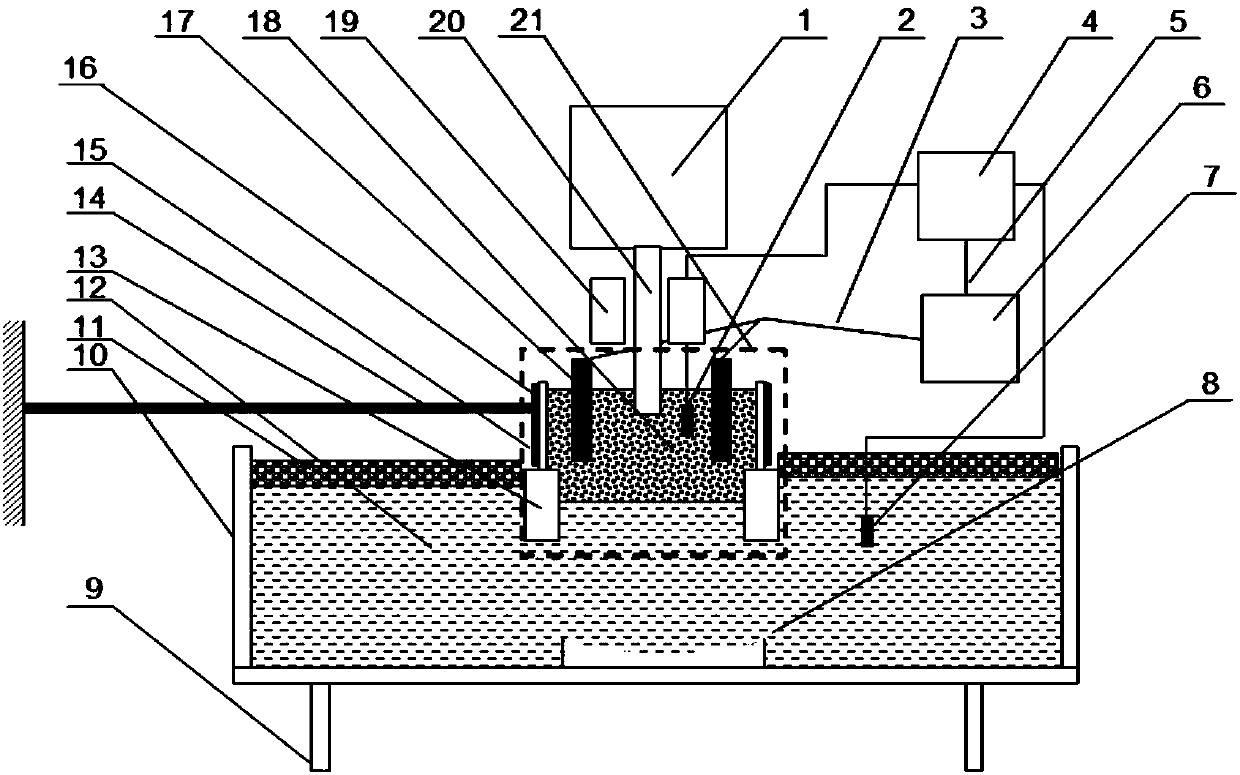

Tundish molten steel slag washing, purifying and heating device and usage method

A technology of tundish and molten steel, which is applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of incomplete removal of inclusions, difficulty in superheat control, etc., to reduce shrinkage cavity and reduce composition Effect of segregation and improvement of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific usage method and effect of the device are as follows:

[0030] Step 1: Adjust the temperature of the molten steel to be cast, so that the temperature of the molten steel in the ladle is lowered from the original 1630°C to 1620°C.

[0031] Step 2: Inject the molten steel in the ladle into the tundish normally, and at the same time add the covering agent into the tundish.

[0032] Step 3: When the molten steel level in the tundish rises to the refractory section at the lower part of the liquid slag pool, gradually inject refining slag into the liquid slag pool, and after the heating electrode is immersed in the refining slag, start the heating power supply manually The liquid refining slag is heated. The weight percentage of refining slag composition is: CaF 265%, Al 2 o 3 20%, CaO 10%, SiO 2 3%, P 0.003%, S 0.003%, and unavoidable impurities. The heating treatment of refining slag includes: calculating the liquidus temperature of the cast steel grade ...

Embodiment 2

[0036] The specific usage method and effect of the device are as follows:

[0037] Step 1: Adjust the temperature of the molten steel to be cast, so that the temperature of the molten steel in the ladle is lowered from the original 1615°C to 1600°C.

[0038] Step 2: inject the molten steel in the ladle into the tundish, and at the same time add the covering agent into the tundish.

[0039] Step 3: When the molten steel level in the tundish rises to the refractory section at the lower part of the liquid slag pool, gradually inject refining slag into the liquid slag pool, and after the heating electrode is immersed in the refining slag, start the heating power supply manually The liquid refining slag is heated. The weight percentage of refining slag composition is: CaF 2 65%, Al 2 o 3 20%, CaO 10%, SiO 2 3%, P 0.003%, S 0.003%, and unavoidable impurities. The heating treatment of refining slag includes: calculating the liquidus temperature of the cast steel grade accordi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap