A high-suction floating oil collection device

A collection device and high suction lift technology, which is applied in the direction of grease/oily substance/floating matter removal device, water treatment parameter control, separation method, etc., can solve the problems of high equipment maintenance rate, cost, unsatisfactory installation and maintenance separation effect, floating Low efficiency of oil collection and other problems, to achieve the effect of wide selection range, easy automatic operation, and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

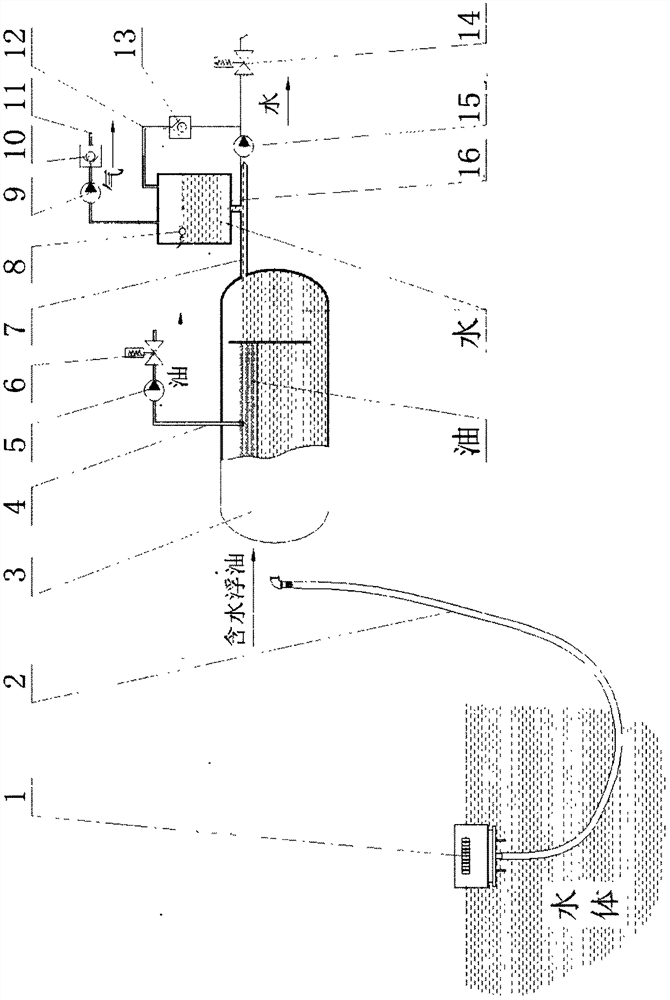

[0027] The utility model relates to a device for collecting floating oil with high suction lift.

[0028] The oil collector 1 placed on the water surface communicates with the inlet port of the airtight oil-water separation device 3 through the oil suction hose 2, and the oil-water separation device 3 is a horizontal airtight negative pressure type oil separation tank; Normally closed oil discharge pipeline 4 and normally closed drain pipeline 7; described normally closed oil discharge pipeline 4 is equipped with oil pump 5 and valve 6, valve 6 is a one-way valve in this case; described normally closed drain pipeline 7 is equipped with a water pump 15 and a valve 14, and the valve 14 is a one-way valve in this case; an airtight water storage tank 16 is established, and the airtight water storage tank 16 communicates with the drain end of the oil-water separation device 3 and the inlet end of the water pump 15; the damping The balance pipe 12 opens in the upper space of the air...

Embodiment 2

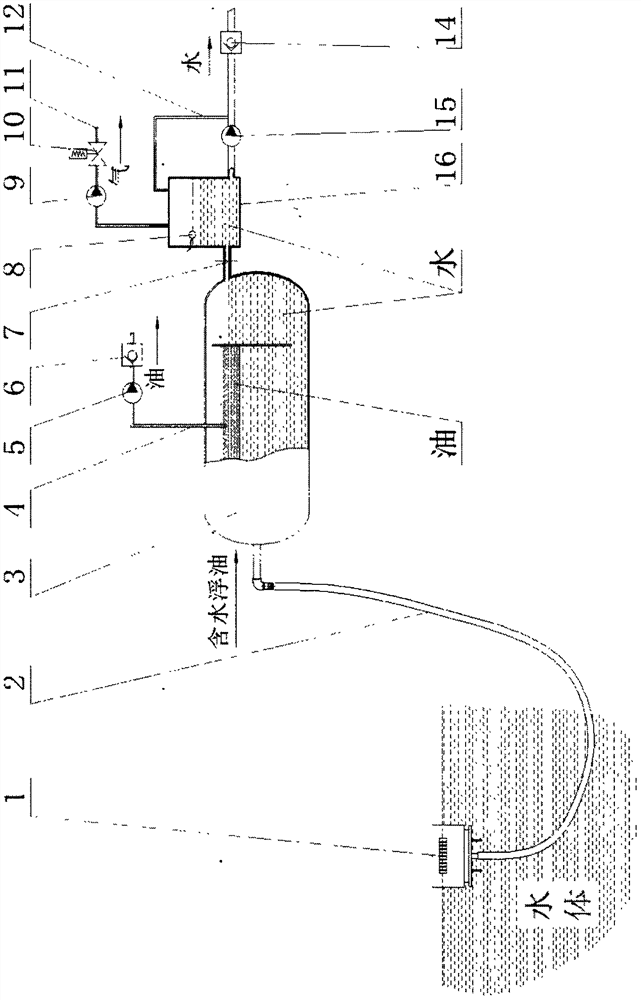

[0030] The utility model relates to a device for collecting floating oil with high suction lift.

[0031]The oil collector 1 placed on the water surface communicates with the inlet of the airtight oil-water separation device 3 through the oil suction hose 2, and the oil-water separation device 3 is a horizontal airtight negative pressure oil separation tank; Closed oil discharge pipeline 4 and normally closed drainage pipeline 7; described normally closed oil discharge pipeline 4 is equipped with oil pump 5 and valve 6, valve 6 is a solenoid valve in this case; described normally closed drainage pipeline 7 is equipped with A pump 15 and a valve 14 are provided. In this case, the valve 14 is a solenoid valve; an airtight water storage tank 16 is arranged outside the oil-water separation device 3, and the lower space of the airtight water storage tank 16 is connected to the normally closed drainage pipeline of the oil-water separation device 3 7 and the inlet port of water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com