Lubricating and antirusting agent for medical appliance with hot-rinsing oil phase transfer performance

A medical device, lubrication and anti-rust technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of incomplete and effective transfer of lubricating anti-rust agent components, uneven coverage, reduced lubrication and anti-rust effect, etc., to improve resources Use efficiency, make full use of resources, enhance the effect of lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

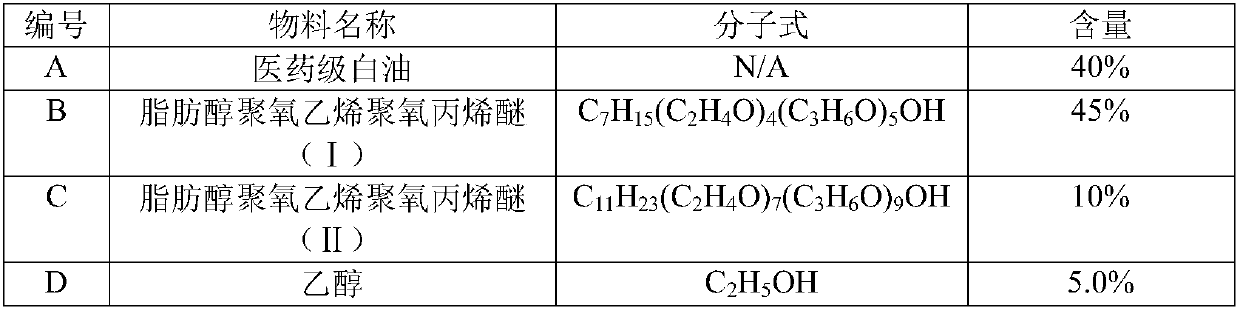

[0028] The preferred materials and component contents in Table 1 are the lubricating and antirust agents for medical devices prepared in Examples, and all percentages are based on weight.

[0029] Table 1

[0030]

[0031] The production process of the embodiment: the raw materials A, B, C and D in Table 1 were sequentially added into a stainless steel container with a stirring device according to the mass percentage content in Table 1 and stirred for 30 minutes.

[0032] The lubricating and antirusting agent for medical devices prepared in the examples is a colorless transparent liquid with stable properties, and no precipitation, crystallization or delamination will occur in indoor storage.

[0033] Tripentanone was added as a fluorescent agent to the lubricating and rust-preventing agent for medical devices at a volume fraction of 0.025% to prepare a lubricating and rust-preventing agent for medical devices containing a fluorescent agent, so that the thickness of the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com