Cable and unshielded and shielded micro-seismic detection cables

A technology for detecting cables and cables. It is applied in the direction of insulated cables, power cables, and cables. It can solve problems such as circuit short circuit, sheath cracks, and cables that cannot pass through, and achieve high breaking force and enhanced tensile resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

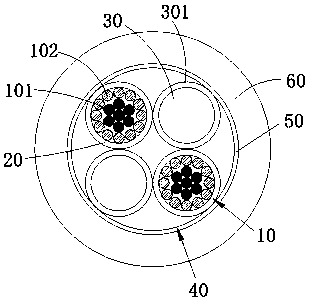

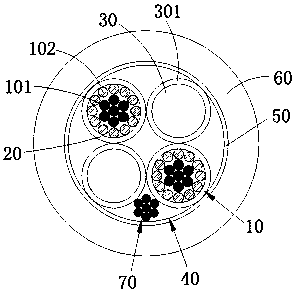

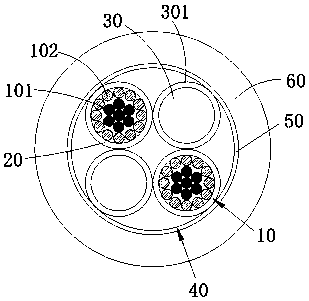

[0051] refer to figure 1 , the present invention provides a cable, which includes an unshielded microseismic detection cable and a shielded microseismic detection cable,

[0052]An unshielded microseismic detection cable provided by the present invention includes: a conductor 10, the conductor 10 includes a central layer 101 twisted with 7 tinned copper foil wires in the center, and the twisting direction is left; and 12 wires located outside the core The outer layer 102 of stranded tinned copper wires is twisted to the right; the insulating layer 20 is extruded on the outside of the conductor 10 with a layer of polyperfluoroethylene propylene layer 301, and the extruded nominal thickness is 0.15 mm ~0.35mm, concentricity ≥ 90%; filling strip 30, the filling strip 30 includes a core formed by aramid fiber and a polyperfluoroethylene propylene layer 301 extruded outside it; an insulated wire core 40, the insulated wire core 40 includes Stranded at least two groups of conductor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com