An on-line hot drawing method for preparing bronze nb 3 sn superconducting wire method

A technology of superconducting wire and bronze method, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. It can solve the problems of inability to draw continuously, achieve short annealing time, convenient operation, and low deformation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Take bronze method Nb with a diameter of 45mm 3 After 2 passes of 20% cold drawing, the Sn bar is placed in a vacuum heat treatment furnace with a temperature accuracy of ±10°C, and evacuated to 6.0×10 -3 Pa, filled with nitrogen, heated to 500 ℃, kept for 2 hours, cooled down and released, after 5 times of the same drawing and annealing, the bronze method Nb with a diameter of 14.7mm was obtained 3 Sn wire 1;

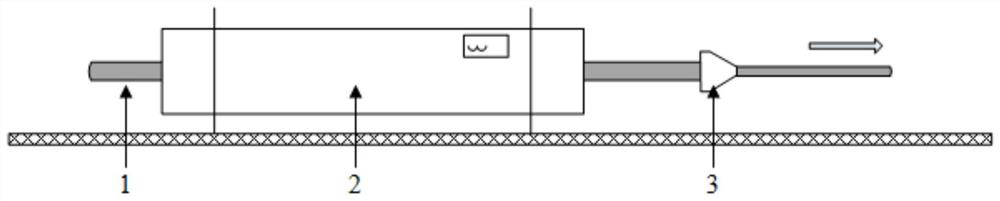

[0021] Step 2: See figure 1 , the tube furnace 2 with a length of 3m and a temperature accuracy of ±10°C is heated to 500°C, and the bronze method Nb 3 The Sn wire passes through the tube furnace 2, passes through the drawing die 3 on the back side of the tube furnace, and passes through a drawing with a processing rate of 20%, and the drawing speed is 5m / min;

[0022] Step 3: Repeat step 2 and repeat 26 times of online heat drawing to obtain bronze method Nb with a diameter of 0.81mm 3 Sn superconducting wire.

[0023] Using the process of cold dra...

Embodiment 2

[0025] Step 1: Take bronze method Nb with a diameter of 40mm 3 After 3 passes of 15% cold drawing, the Sn bar is placed in a vacuum heat treatment furnace with a temperature accuracy of ±10°C, and evacuated to 7.0×10 -3 Pa, filled with nitrogen, heated to 520 ℃, kept for 2 hours, cooled down and released, after 5 times of the same drawing and annealing, the bronze method Nb with a diameter of 11.8mm was obtained 3 Sn wire 1;

[0026] Step 2: See figure 1 , the tube furnace 2 with a length of 3m and a temperature accuracy of ±10°C is heated to 550°C, and the bronze method Nb 3 The Sn wire passes through the tube furnace 2, passes through the drawing die 3 on the rear side of the tube furnace, and passes through a drawing with a processing rate of 15%, and the drawing speed is 14m / min;

[0027] Step 3: Repeat step 2 and repeat 33 times of online heat drawing to obtain bronze method Nb with a diameter of 0.81mm 3 Sn superconducting wire.

[0028] Using the process of cold dr...

Embodiment 3

[0030] Step 1: Take bronze method Nb with a diameter of 32mm 3 After 3 passes of 14% cold drawing, the Sn bar is placed in a vacuum heat treatment furnace with a temperature accuracy of ±10 °C, and the vacuum is evacuated to 4.0×10 -3 Pa, filled with nitrogen, heated to 450 ℃, kept for 2 hours, cooled down and released, and after 5 times of the same drawing and annealing, a bronze method Nb with a diameter of 7.1 mm was obtained. 3 Sn wire 1;

[0031] Step 2: See figure 1 , the tube furnace 2 with a length of 3m and a temperature accuracy of ±10°C is heated to 450°C, and the bronze method Nb 3 The Sn wire passes through the tube furnace 2, passes through the drawing die 3 on the back side of the tube furnace, and passes through a drawing with a processing rate of 14%, and the drawing speed is 10m / min;

[0032] Step 3: Repeat step 2 and repeat 26 times of online heat drawing to obtain bronze method Nb with a diameter of 1.0mm 3 Sn superconducting wire.

[0033] Using the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com