PTC current protection device

A current protection and PTC technology, applied in the field of PTC current protection devices containing PTC polymer materials, can solve problems such as improvement and insufficient stability, and achieve the effect of good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]

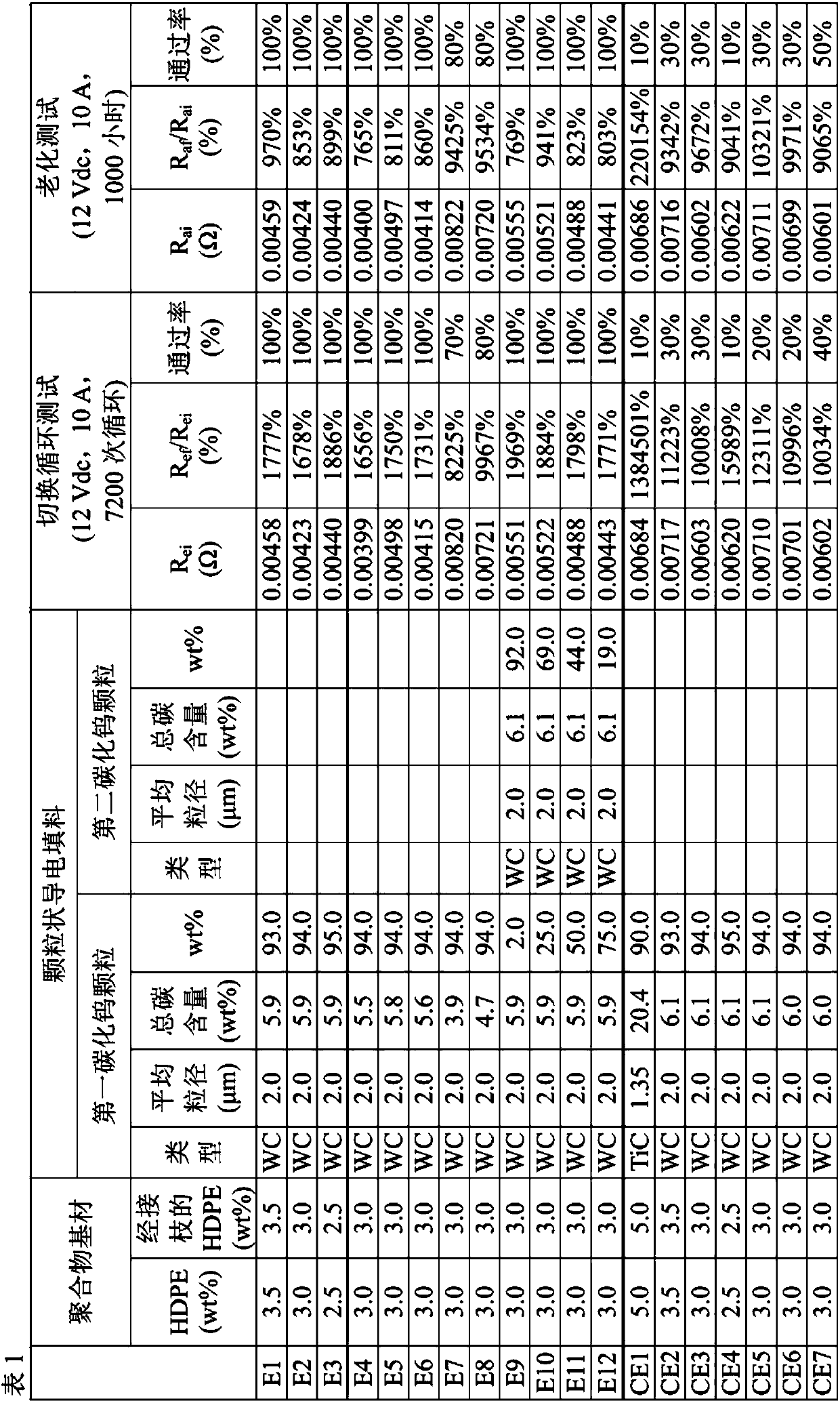

[0025] 10.5g HDPE (purchased from Taiwan Plastic Industry Co., Ltd., product model: HDPE9002, as non-grafted polyolefin), 10.5g HDPE grafted with maleic anhydride (purchased from DuPont, product model: MB100D, used as the Carboxylic anhydride grafted polyolefin), and 279g tungsten carbide particles [produced in an environment at about 1750°C and in the presence of hydrogen, the total carbon content is 5.9wt%, and the average particle size is 2.0 μm (by Fischer microsieve Classifier FSSS measurement), as the first tungsten carbide particles of granular conductive filler 22] mixed ingredients in a mixer (brand: Brabender), with a temperature of 200 ° C, a stirring speed of 50 rpm and a pressurized weight of 5 kg The ingredients were mixed for 10 min to obtain a mixture.

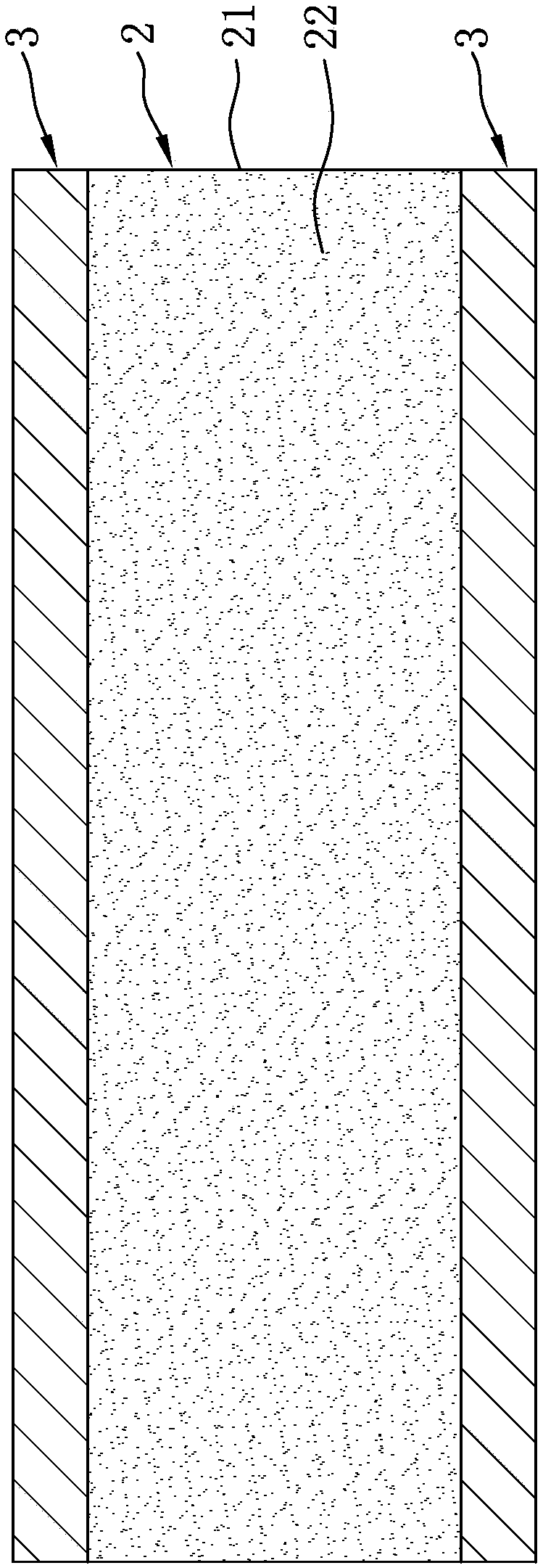

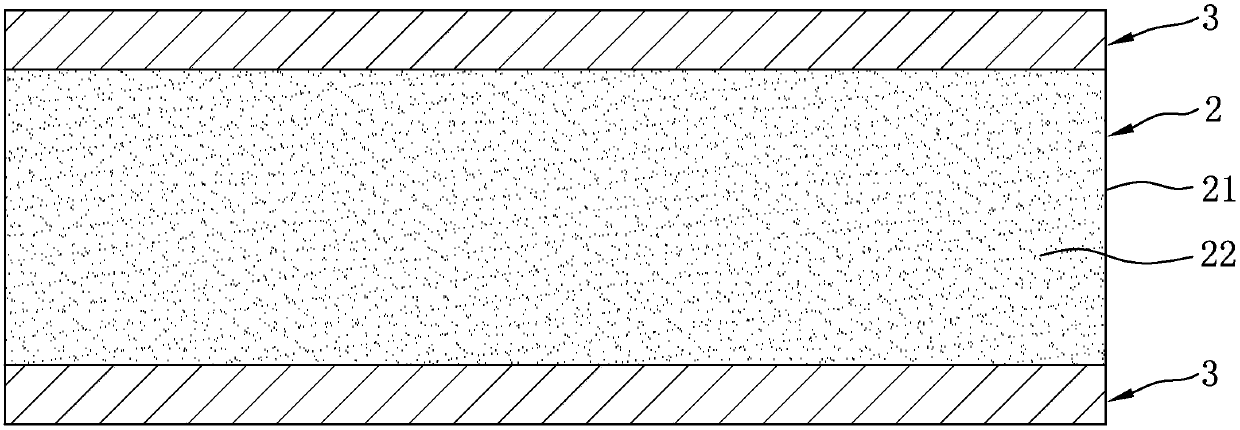

[0026] The mixture is hot-pressed at a temperature of 200°C and a pressure of 80kg / cm 2 The conditions were hot-pressed for 4 min to form a thin sheet of PTC polymer material 2 with a thickness of 0...

Embodiment 2 and 3

[0028]

[0029] The process conditions of the test samples in Examples 2 and 3 (E2 and E3) are similar to those in Example 1, except that the usage amounts of the first tungsten carbide particles, HDPE and grafted HDPE were changed as shown in Table 1.

Embodiment 4 to 8

[0030]

[0031] The process conditions of the test samples in Examples 4 to 8 (E4-E8) are similar to those in Example 2, except that the total carbon content of the first tungsten carbide particles is changed as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com