Sealing structure of aluminum-plastic composite sheath high-voltage cable joint

A high-voltage cable, aluminum-plastic composite technology, used in cable joints, cable installation, cable accessories, etc., can solve problems such as inability to burn lead seals, and achieve excellent waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

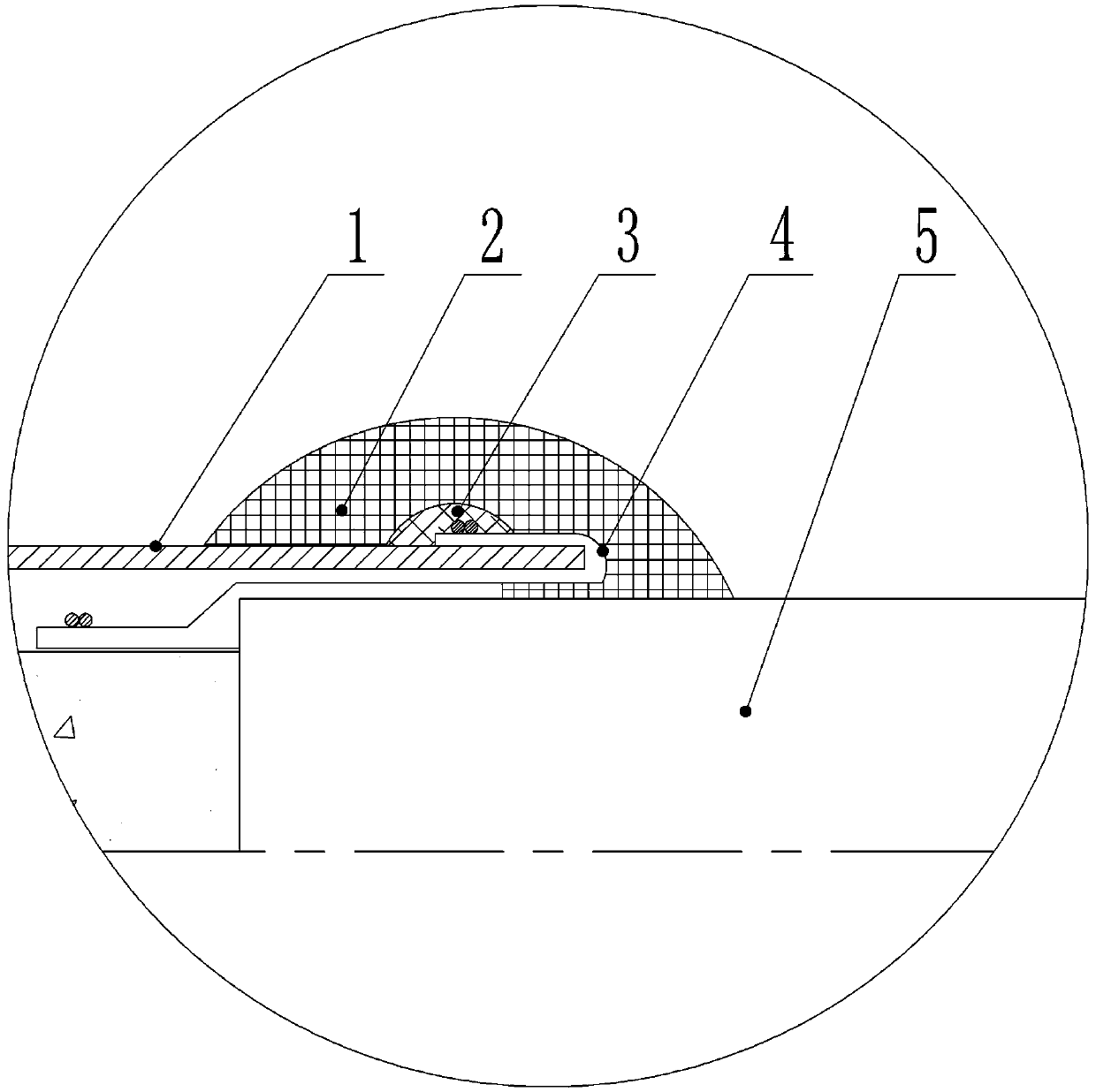

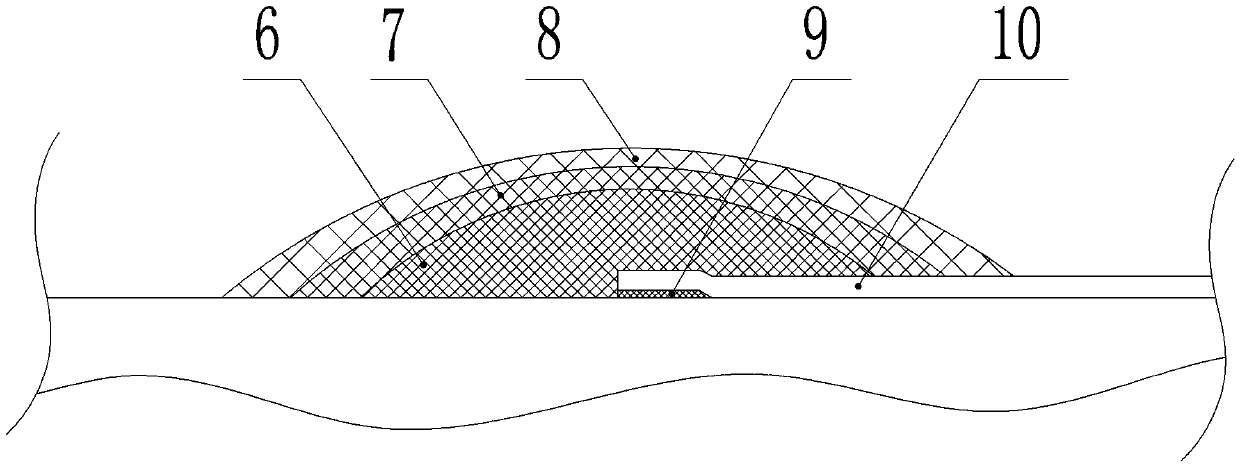

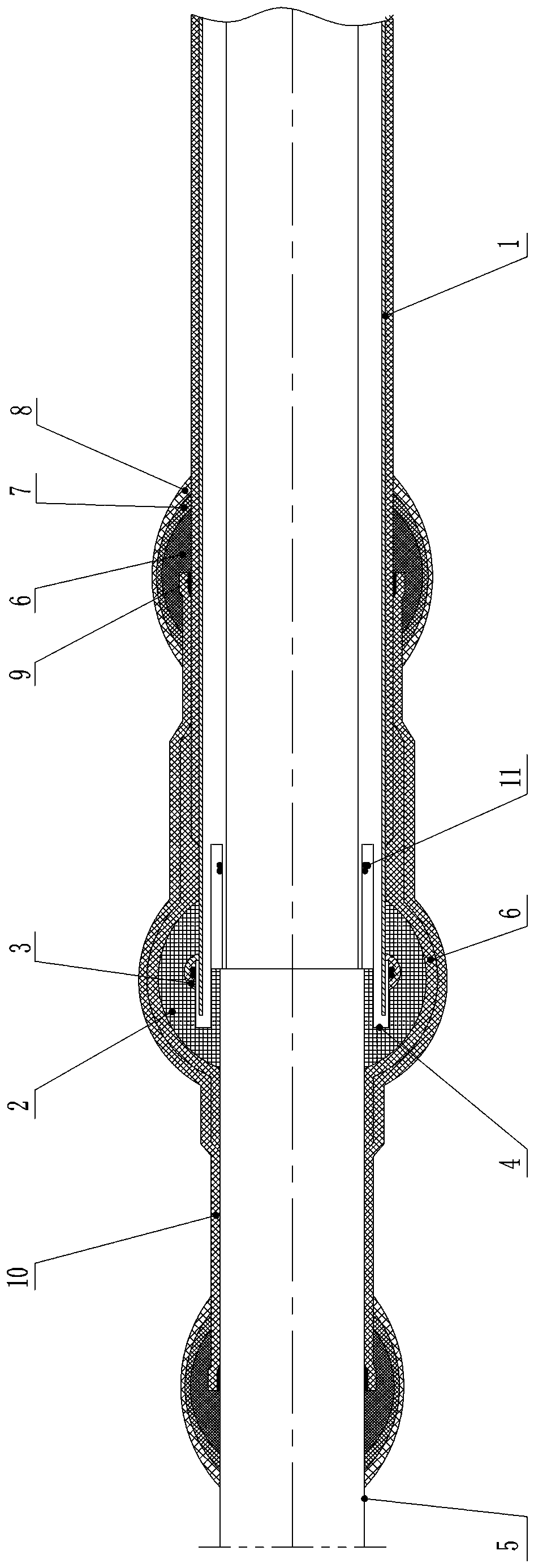

[0015] According to attached figure 1 , attached figure 2 And attached image 3 , the invention is a waterproof sealing structure of a high-voltage cable joint with aluminum-plastic composite sheath, including two sections of aluminum-plastic composite sheath high-voltage cable and a copper shell around the cable joint, as well as plastic composite materials for fixing the copper shell and copper Insulated heat-shrinkable tubes and various tapes for waterproofing the shell. The present invention uses plastic composite materials to seal and fix the cable joints to replace the existing sealing method of using metal sheaths to seal high-voltage cable joints. Realize the axial sealing of the cable, so as to realize the reliable waterproof of the high-voltage cable joint.

[0016] The concrete operation that realizes sealing structure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com