Continuous detection device used after electric heating pipe shrinkage

A detection device and electric heating tube technology, which is applied in the direction of measuring devices, only measuring voltage, measuring electrical variables, etc., can solve problems such as limited processing efficiency, error-prone, and inability to automate processing, and achieve the effect of improving detection accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

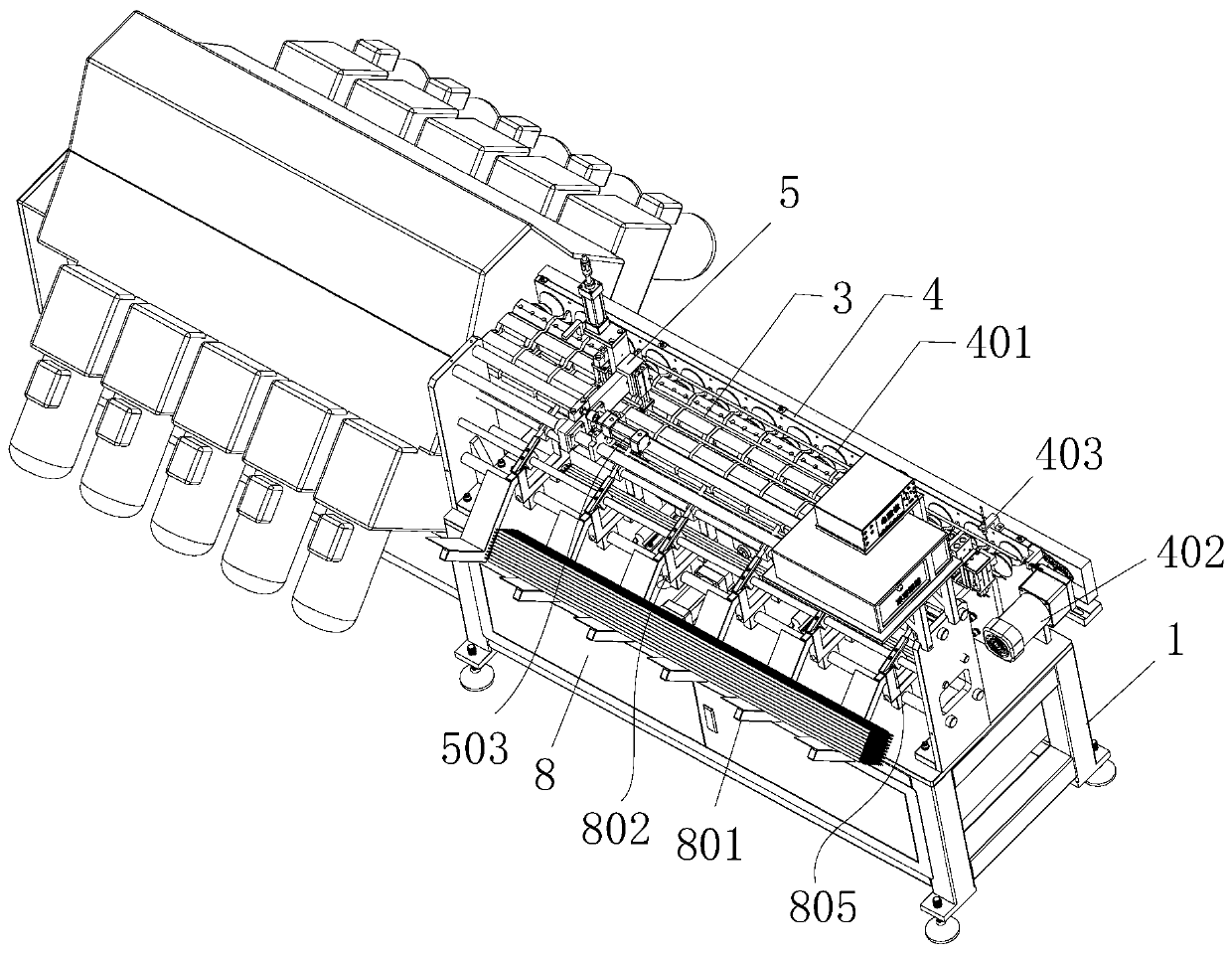

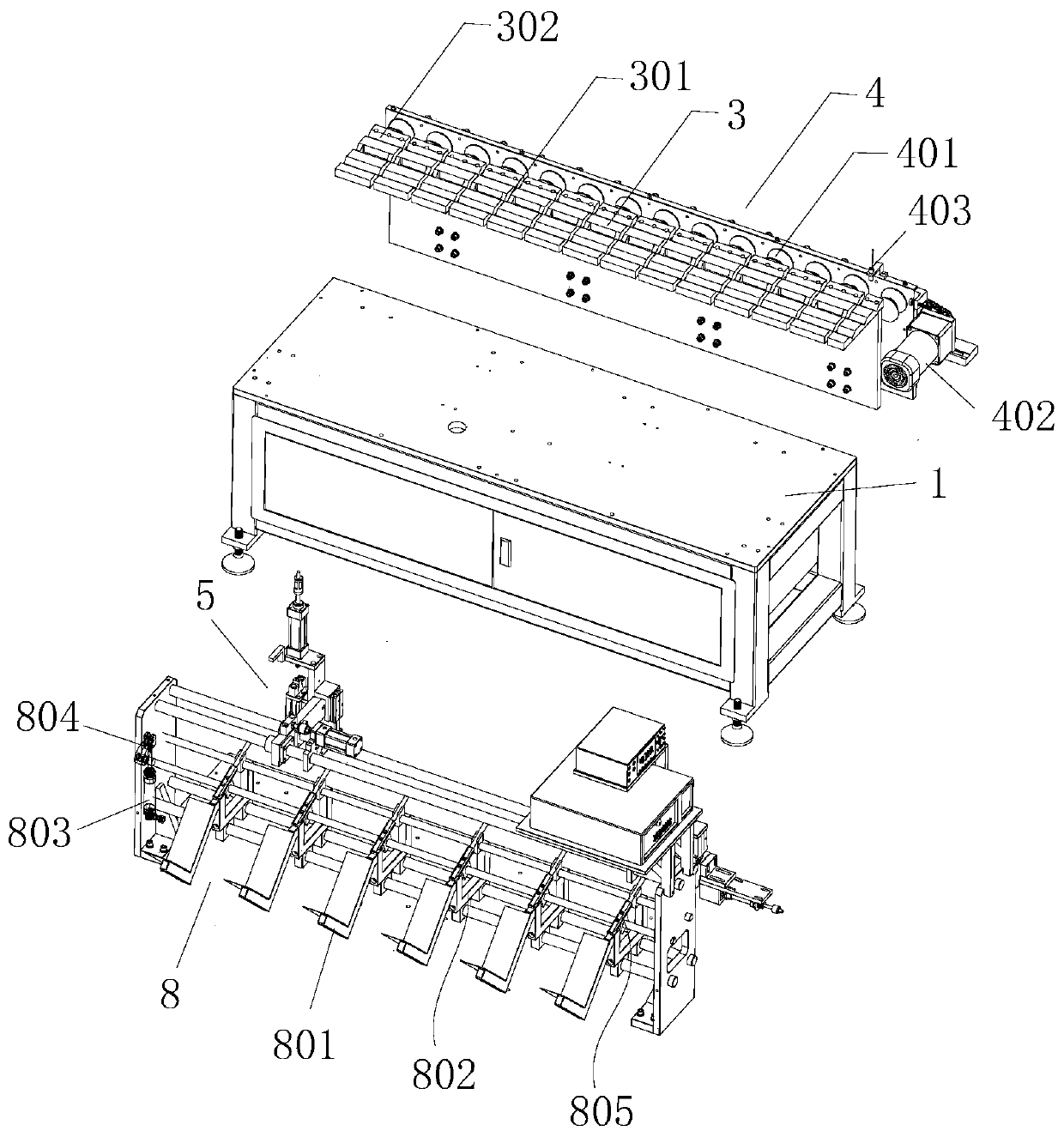

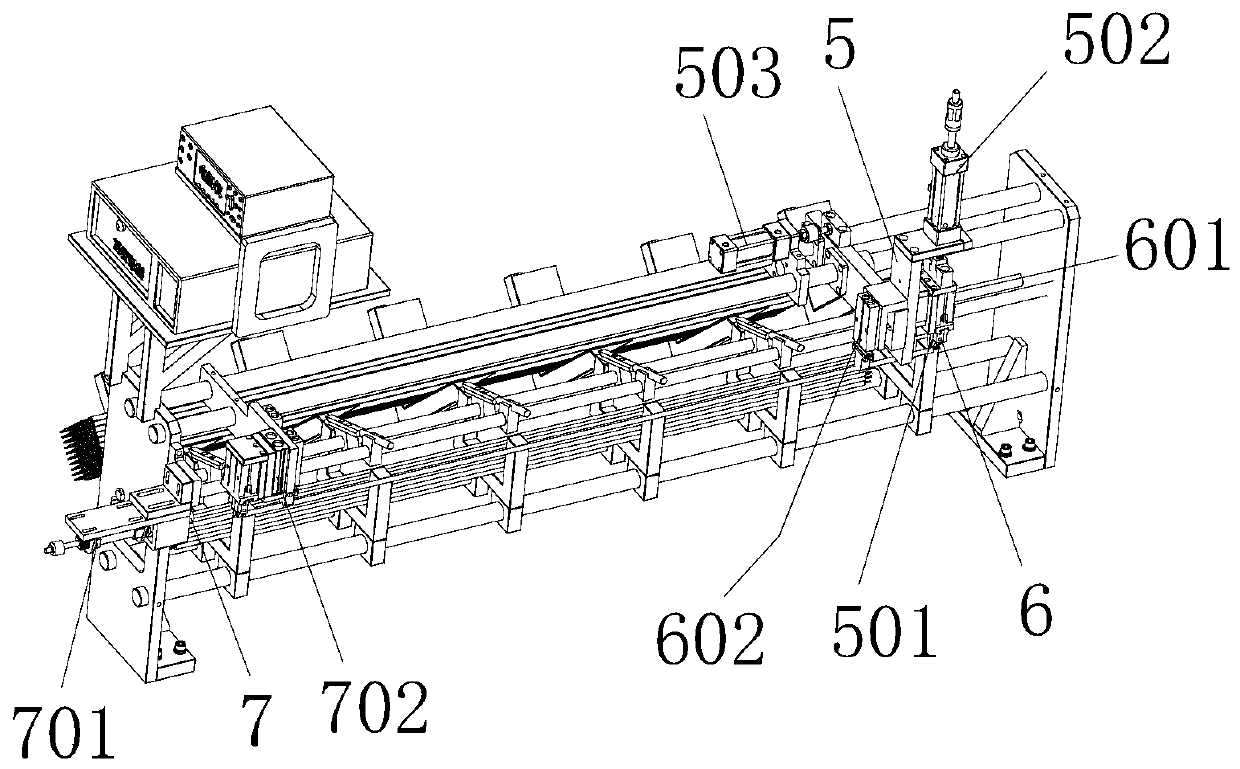

[0038] Attached below Figure 1-5 The present invention is described in further detail.

[0039] A continuous detection device for electric heating tube shrinkage, comprising:

[0040] Rack 1, as in figure 1 As shown, the frame 1 is set on one side of the tube shrinking machine, and the frame 1 is provided with a tube transportation rack 2, a tube placement platform 3 and a tube delivery device 4, and the tube delivery device 4 can send the electric heating tube processed by the tube shrinking machine to To the side of tube placement platform 3;

[0041] Insertion station 3, such as Figure 4 As shown, the tube placement platform 3 is provided with a custodial groove 301 for extending the transport tube rack 2 and a limiting groove 302 for placing the heating tube;

[0042] Pipe rack 2, such as Figure 5 As shown, the pipe transport rack 2 is arranged under the tube placement platform 3, and the pipe transport rack 2 can make the heating tube move back and forth on the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com