Welding machine control system and control method thereof

A control system and control method technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of poor welding state feedback control ability of automatic welding machines, and achieve the effect of ensuring the accuracy of analysis and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

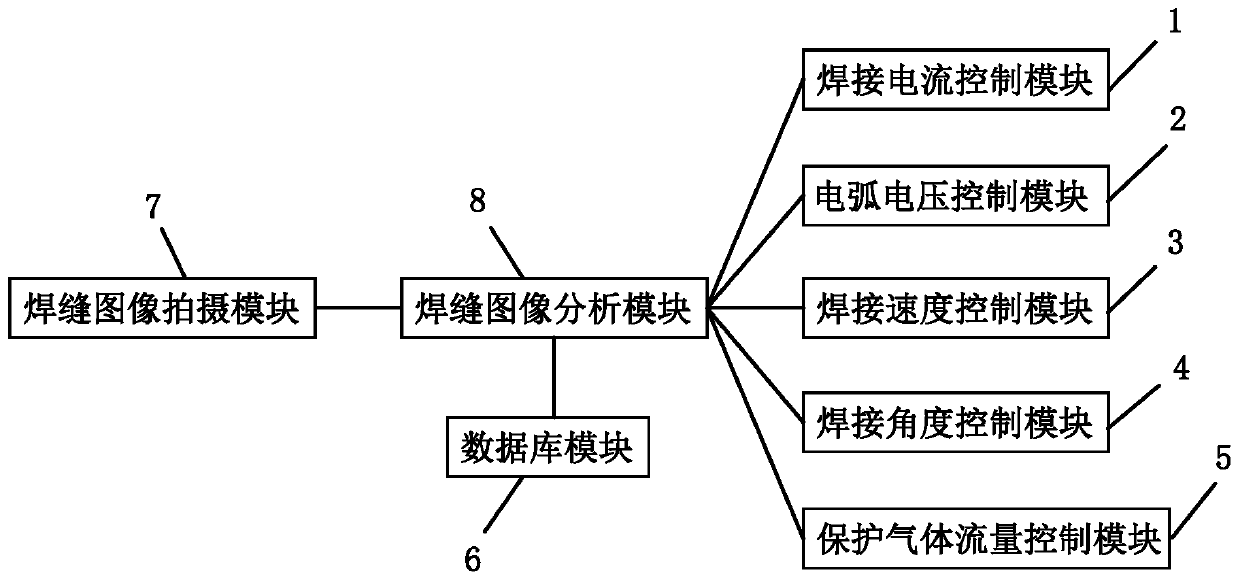

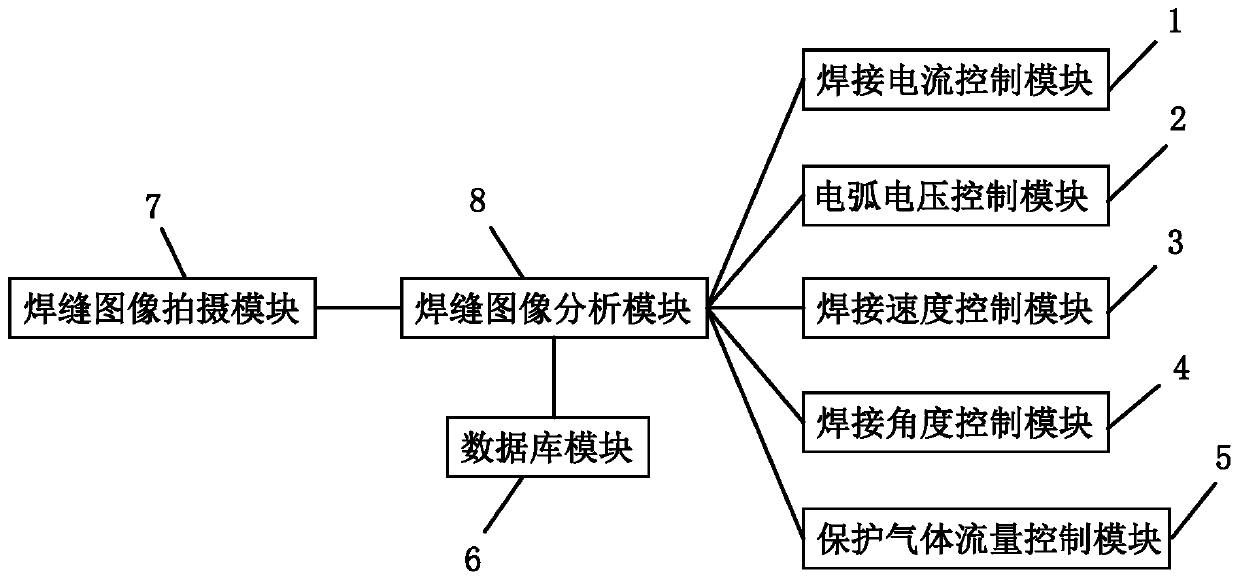

[0037] refer to figure 1 , a specific embodiment of the present invention includes, a welding current control module 1, used to control the welding current;

[0038] The arc voltage control module 2 is used to control the arc voltage;

[0039] The welding speed control module 3 is used to control the welding speed;

[0040] The welding angle control module 4 is used to control the welding angle;

[0041] The shielding gas flow control module 5 is used to control the shielding gas flow;

[0042] The database module 6 is used to save the tabular data of the welding seam state and the welding parameter adjustment method;

[0043] Weld seam image shooting module 7, used for taking weld seam images;

[0044] The weld image analysis module 8 is configured to analyze the captured weld images.

[0045] A control method of the above-mentioned welding machine control system, comprising the following steps:

[0046] A. The welding machine starts the welding operation according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com