Intelligent stainless steel pipe inner wall polishing device

A technique for polishing devices and stainless steel pipes, which is applied in grinding/polishing safety devices, grinding/polishing equipment, and surface polishing machine tools, etc., which can solve the problem of easy pollution of the environment due to dripping of abrasive liquid at the angle of liquid injection, and inconvenient fixing of stainless steel pipe fittings , It is inconvenient to adjust the grinding liquid and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

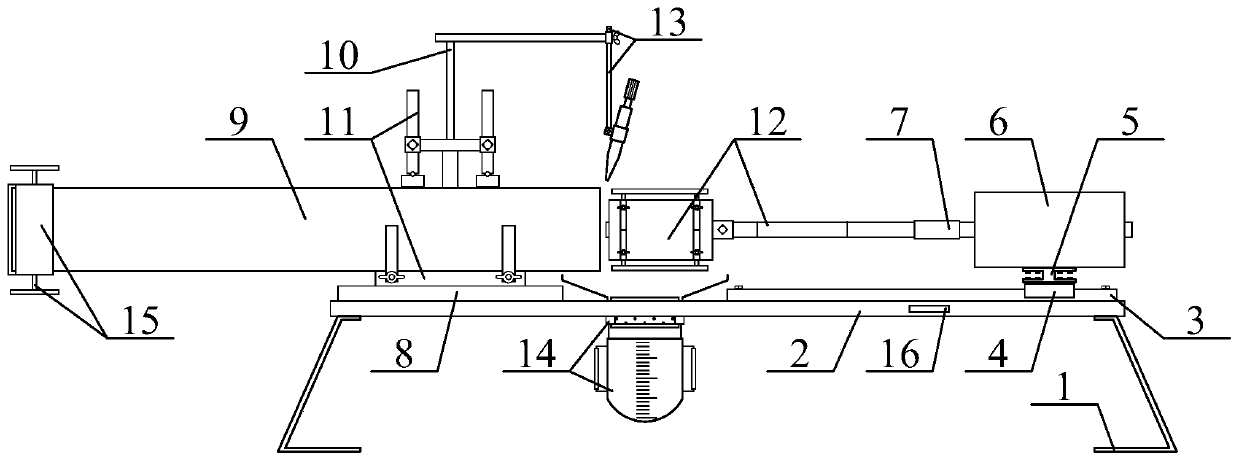

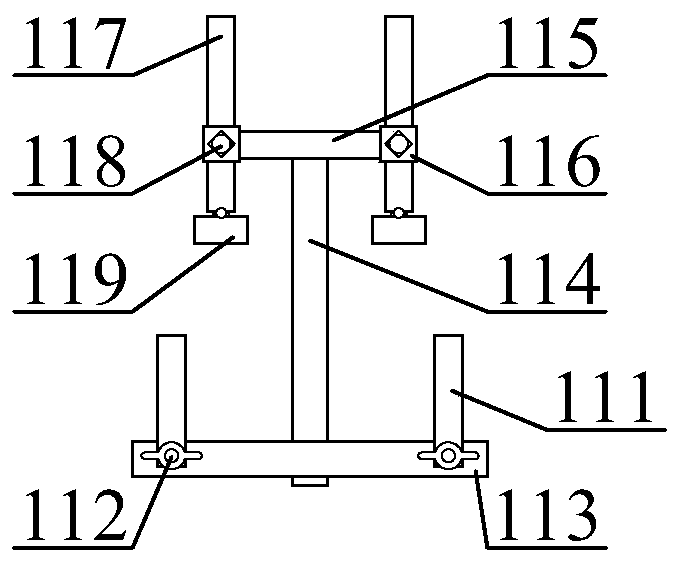

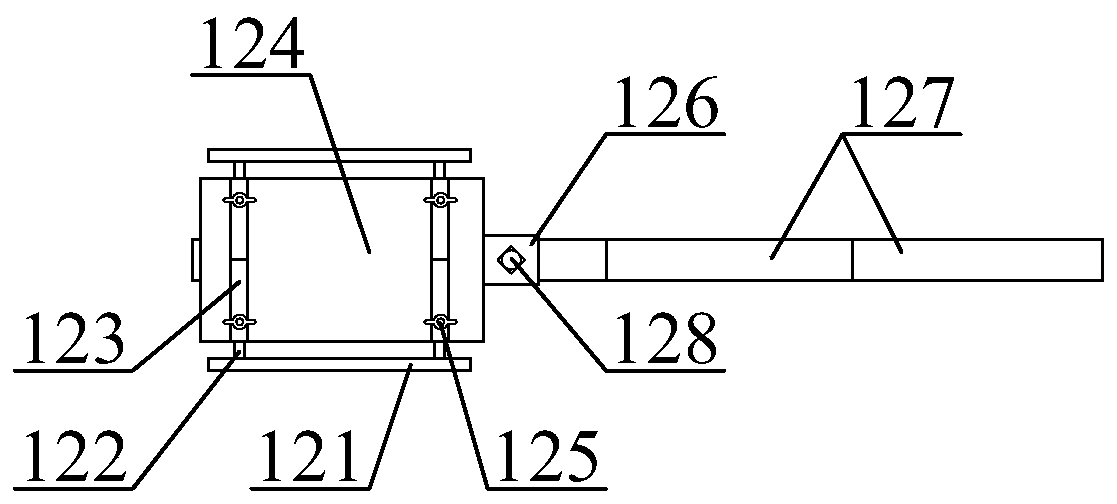

[0048] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an intelligent polishing device for the inner wall of stainless steel pipe fittings includes support legs 1, frame 2, linear slide rail 3, U-shaped slider 4, I-shaped frame 5, polishing motor 6, and sleeve coupling 7 , mounting base 8, stainless steel pipe fittings to be polished 9, column 10, multi-position auxiliary adjustable pipe fitting clamping clamp 11, telescopic adjustment of polishing rod position moving rod structure 12, multi-position adjustable abrasive liquid injection nozzle structure 13, abrasive liquid Drip auxiliary collection filter tank structure 14, plugging cap structure 15 and intelligent control switch 16 can be observed at the end of the pipe fittings, and the support legs 1 are respectively bolted to the bottom four corners of the frame 2; the linear slide rail 3 The horizontal bolt is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com