Weaving machine tensioning mechanism

A technology of tensioning mechanism and weaving machine, applied in the direction of online netting, other household appliances, and conveying filamentous materials, etc., can solve the problems of complex mechanism, unfavorable equipment repair and maintenance, and inconvenience of production work, so as to achieve precise control and facilitate the later stage Maintenance and repair, the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

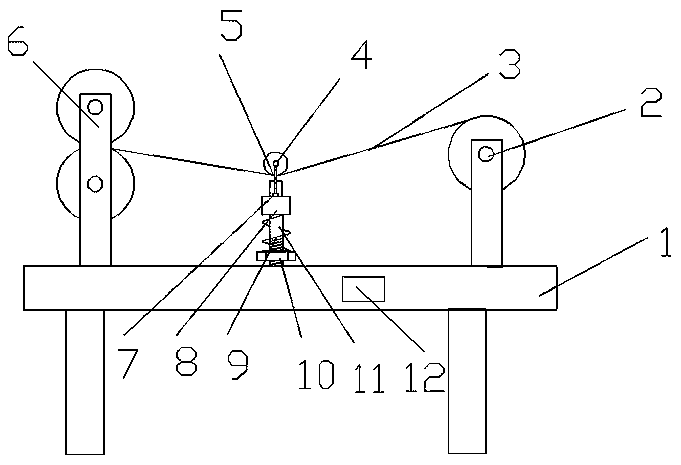

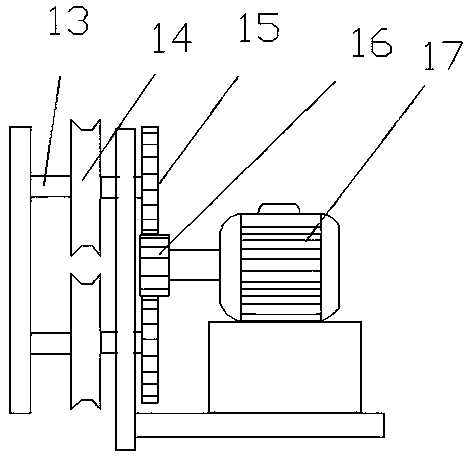

[0019] see Figure 1-2 , a braiding machine tensioning mechanism, including a table 1 and a driving device 6. The right end of the upper surface of the workbench 1 is rotatably connected with a bobbin 2, and the braided wire 3 to be braided is wound on the bobbin 2. The left end of the bobbin 2 is fixed with a vertical guide rod 11, and the guide rod 11 is nested Counterweight 8 is arranged, and counterweight 8 can slide on guide bar 11. The upper surface of the counterweight 8 is connected to the bottom of the connecting rod 5, the top of the connecting rod 5 is rotatably connected with the sliding wheel 4, and a tension sensor 7 is arranged between the bottom of the connecting rod 5 and the counterweight 8, and the tension sensor 7 can sense The tension between the counterweight 8 and the connecting rod 5. The lower end of the guide rod 11 is provided with a thread, and a nut 10 is nested on the thread, and a spring 9 is nested on the guide rod 11 between the nut 10 and th...

Embodiment 2

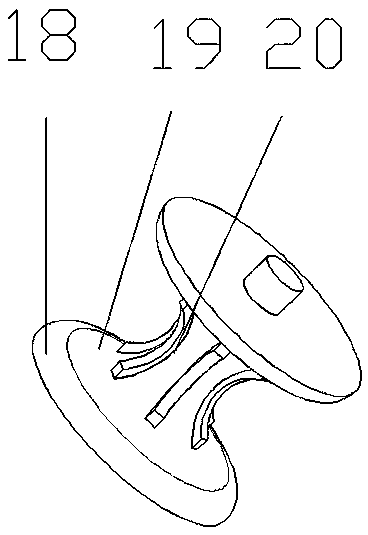

[0023] see image 3 , On the basis of Embodiment 1, the rotating roller 14 includes a crimp 18 and a plastic roller 19, the crimp 18 is symmetrically arranged on the outer end of the plastic roller 19, and the setting of the crimp 18 makes the braided wire 3 better enter the plastic roller 19 inside, to avoid derailment of braided wire 3. The side wall of plastic roller 19 is provided with some rubber teeth 20, and the setting of rubber teeth 20 has increased the frictional force between braided wire 3 and plastic roller 19, avoids the occurrence of slipping phenomenon in the transmission process, makes tightness adjustment more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com