High-extraction-rate preparation method for curcumin

A technology of curcumin and extraction rate, which is applied in the field of preparation of high extraction rate of curcumin, can solve the problem of low extraction rate, achieve the effect of improving extraction rate and cell disruption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing curcumin with high extraction rate, comprising the steps of:

[0031] Step 1, fully mixing absolute ethanol, inorganic salts, anhydrous methanol, and distilled water to form an extraction reaction solution;

[0032] Step 2, adding turmeric powder to the extraction reaction solution for 30 minutes of low-temperature ultrasonic reaction, and 20 minutes of microcurrent reaction to obtain a release solution;

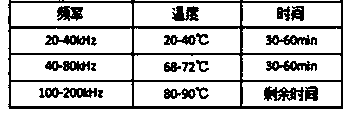

[0033] Step 3, put the release liquid into the reaction kettle for gradient ultrasonication for 3 hours to obtain the extract;

[0034] In step 4, the extract is centrifuged at a constant temperature and filtered to obtain a curcumin crude extract, and then the curcumin crude extract is eluted and concentrated to obtain curcumin.

[0035] The mass proportioning of the extraction reaction liquid of described step 1 is as follows:

[0036] 10 parts of absolute ethanol, 30 parts of absolute methanol, 5 parts of distilled water, 2 parts of inorgan...

Embodiment 2

[0044] A method for preparing curcumin with high extraction rate, comprising the steps of:

[0045] Step 1, fully mixing absolute ethanol, inorganic salts, anhydrous methanol, and distilled water to form an extraction reaction solution;

[0046] Step 2, adding turmeric powder to the extraction reaction solution for 60 minutes of low-temperature ultrasonic reaction, and 50 minutes of microcurrent reaction to obtain a release solution;

[0047] Step 3, put the release solution into the reaction kettle for gradient ultrasonication for 5 hours to obtain the extract solution;

[0048] In step 4, the extract is centrifuged at a constant temperature and filtered to obtain a curcumin crude extract, and then the curcumin crude extract is eluted and concentrated to obtain curcumin.

[0049] The mass proportioning of the extraction reaction liquid of described step 1 is as follows:

[0050] 20 parts of absolute ethanol, 50 parts of absolute methanol, 10 parts of distilled water, 6 part...

Embodiment 3

[0058] A method for preparing curcumin with high extraction rate, comprising the steps of:

[0059] Step 1, fully mixing absolute ethanol, inorganic salts, anhydrous methanol, and distilled water to form an extraction reaction solution;

[0060] Step 2, adding turmeric powder to the extraction reaction solution for 50 minutes of low-temperature ultrasonic reaction, and 40 minutes of microcurrent reaction to obtain a release solution;

[0061] Step 3, put the release solution into the reaction kettle for gradient ultrasonication for 4 hours to obtain the extract solution;

[0062] In step 4, the extract is centrifuged at a constant temperature and filtered to obtain a curcumin crude extract, and then the curcumin crude extract is eluted and concentrated to obtain curcumin.

[0063]The mass proportioning of the extraction reaction liquid of described step 1 is as follows:

[0064] 15 parts of absolute ethanol, 40 parts of absolute methanol, 8 parts of distilled water, 4 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com