Method for producing pleurotus nebrodensis polysaccharide by compound enzymatic hydrolysis technology

A technology of compound enzymatic hydrolysis and Linggu polysaccharide, applied in the field of Bailing mushroom polysaccharide preparation, can solve the problems of large loss of active ingredients, low extraction rate, and failure to meet market demand, and achieve functional diversification and high polysaccharide extraction rate , the effect of reducing the burden on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

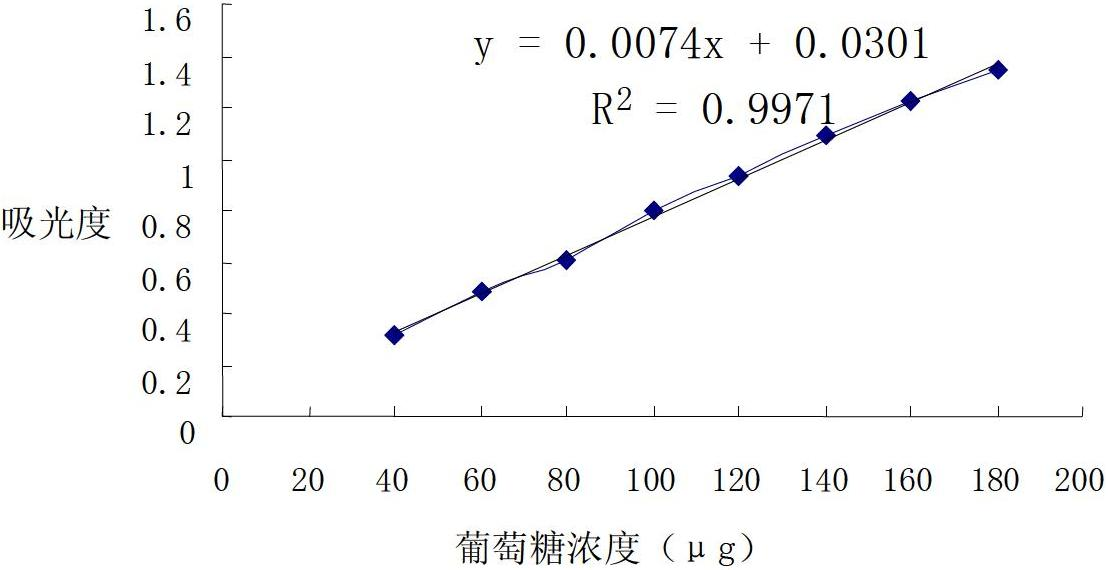

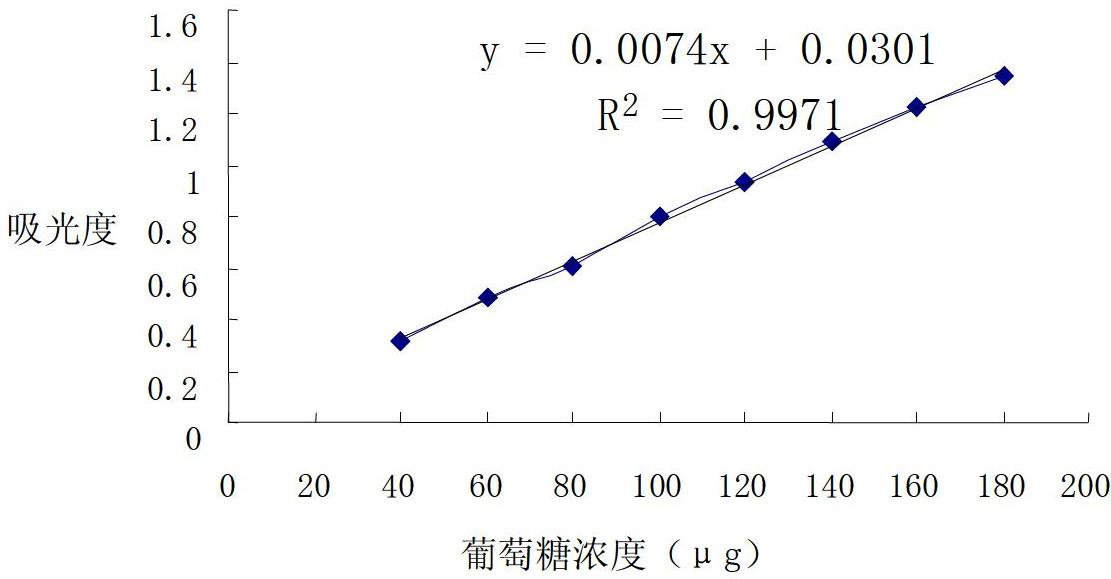

Image

Examples

Embodiment 1

[0035] A method for producing Bailing mushroom polysaccharide by using compound enzymolysis technology, comprising the steps of:

[0036] (1) Raw material processing: Wash Bailing mushroom as a raw material, drain it, dry it in vacuum, and crush it into 80 mesh Bailing dry powder; this raw material is the waste in the processing of Bailing mushroom, including Bailing deformed mushroom , broken old edges and stalks during production, and remaining Bailing mushroom roots after picking; (2) Compound enzymolysis with cellulase and pectinase: mix Bailing mushroom dry powder with distilled water at a mass ratio of 1:30 After soaking for 30min, the mass concentration is 0.5% dilute hydrochloric acid and adjusted to pH 5.0, adding the compound enzyme of cellulase and pectinase with 2% mass of Bailing mushroom powder, the quality of cellulase and pectinase in the compound enzyme The ratio is 1:1. After the incubation reaction at 70°C for 1.5h, the temperature is immediately raised to 9...

Embodiment 2

[0041] A method for producing Bailing mushroom polysaccharide by using compound enzymolysis technology, comprising the steps of:

[0042] (1) Raw material processing: wash the remaining Bailing mushroom root as raw material, drain it, dry it in vacuum, and crush it into 100 mesh Bailing mushroom dry powder; this raw material is the waste in the processing of Bailing mushroom, including Bailing mushroom Deformed mushrooms, old edges and stalks broken during production, and leftover roots of Bailing mushrooms after picking;

[0043] (2) Composite enzymatic hydrolysis with cellulase and pectinase: mix Bailing mushroom dry powder with distilled water at a mass ratio of 1:10, soak for 60 minutes, adjust the pH to 6.0 with 0.5% dilute hydrochloric acid, add Bailing A compound enzyme with 1% mushroom powder mass, the mass ratio of cellulase and pectinase in the compound enzyme is 2:1, heat at 60°C for 3 hours, then immediately heat up to 95°C to inactivate the enzyme, and continue to...

Embodiment 3

[0047] A method for producing Bailing mushroom polysaccharide by using compound enzymolysis technology, comprising the steps of:

[0048] (1) Raw material processing: Wash the old edge or stalk of the broken Bailing mushroom, drain it, dry it in vacuum, and crush it into 80 mesh Bailing mushroom dry powder; this raw material is the waste in the processing of Bailing mushroom, including Bailing mushroom Deformed mushrooms, old edges and stalks broken during production, and leftover roots of Bailing mushrooms after picking;

[0049] (2) Composite enzymatic hydrolysis with cellulase and pectinase: mix Bailing mushroom dry powder with distilled water at a mass ratio of 1:20, soak for 45 minutes, adjust the pH to 7.0 with 0.5% dilute hydrochloric acid, add Bailing The compound enzyme with 0.5% mushroom powder mass, in which the mass ratio of cellulase and pectinase is 3:1, put it at 50°C for 2.5 hours, heat it up to 100°C to kill the enzyme, and continue to soak in a water bath at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com