Masonry structure with coal charging hole, smoke guide hole or ascending pipe hole

A technology of masonry structure and coal charging holes, which is applied in the direction of coke oven bricklaying operations, etc., can solve the problems of cracking and collapsing of overhead bricks, cracking of overhead bricks, collapse of carbonization chamber, etc., and achieves easy manufacturing and masonry strength. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

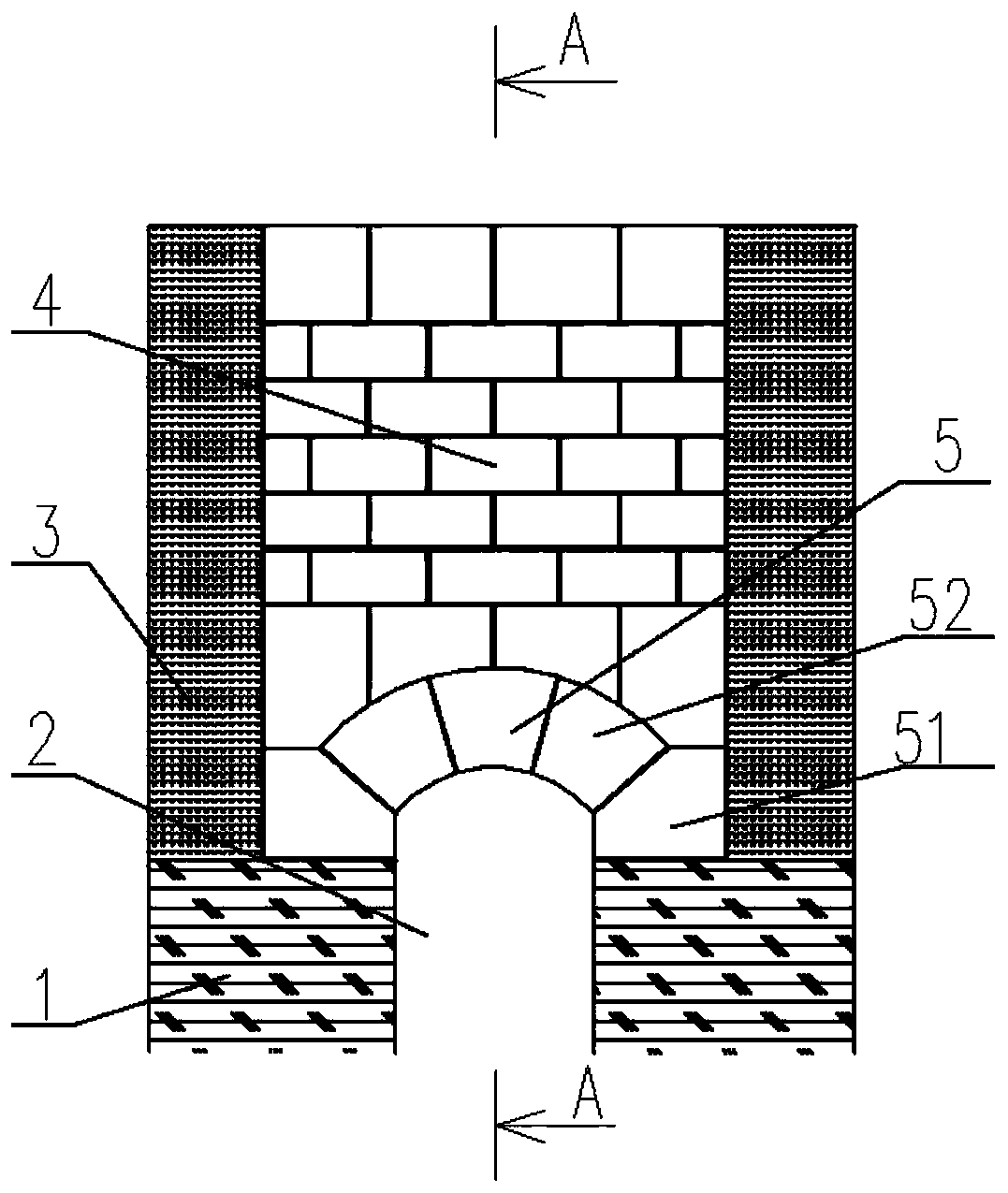

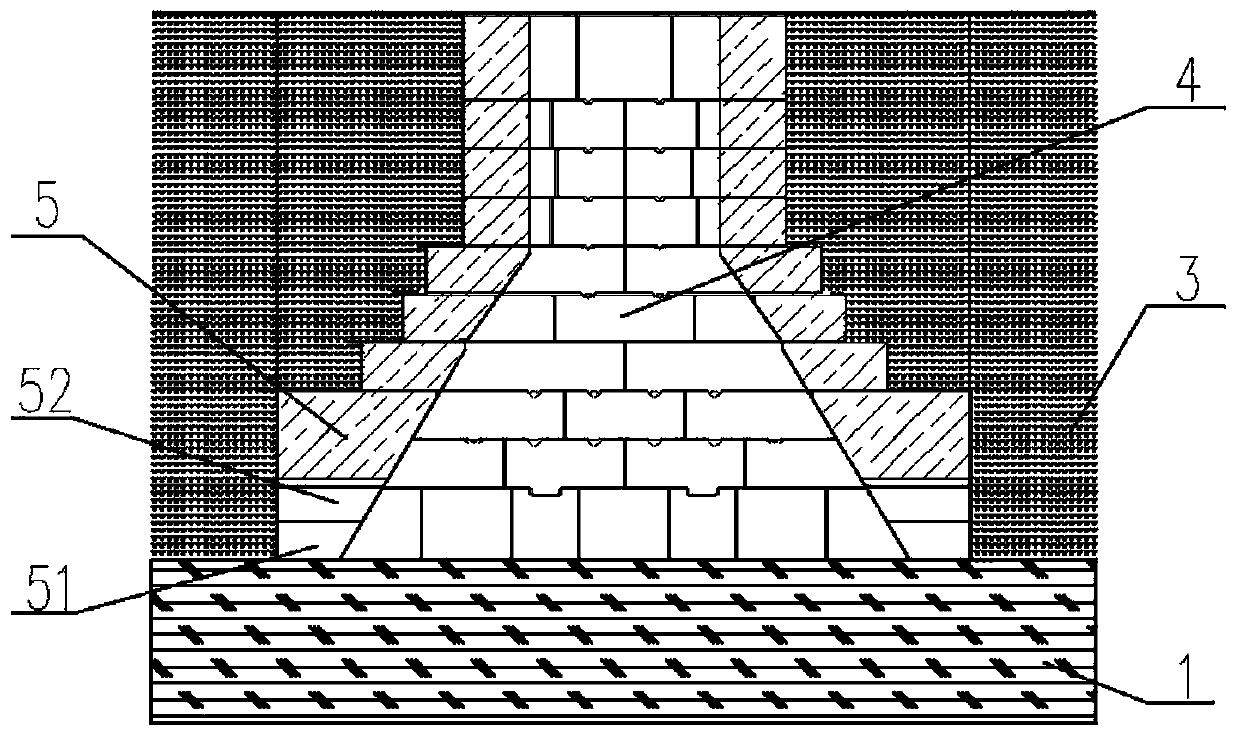

[0020] Such as figure 1 , figure 2 As shown, the masonry structure of a coal charging hole, smoke guiding hole or rising pipe hole according to the present invention includes a coal charging hole masonry, a smoke guiding hole masonry or a rising pipe made of multi-layer refractory bricks. Hole masonry, hereinafter collectively referred to as masonry 4; the bottom of said masonry 4 is an arched structure 5 composed of arched bricks 51 and wedge-shaped bricks 52, and arched bricks 51 are built on both sides of the arched structure 5, The tops of the two combustion chambers 1 located on both sides of the corresponding carbonization chamber 2 respectively, and the middle part of the arched structure 5 is built with wedge-shaped bricks 52 , and the wedge-shaped bricks 52 are located above the corresponding carbonization chamber 2 .

[0021] The arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com