A heat treatment method for spray-formed 7055 aluminum alloy

A heat treatment method and spray forming technology, applied in the field of aluminum alloy processing technology, can solve the problems of difficulty in ensuring material strength, increase of precipitated phase coarsening rate, difficulty in controlling regression time, etc., and achieve small performance fluctuation, high strength and toughness, and long holding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

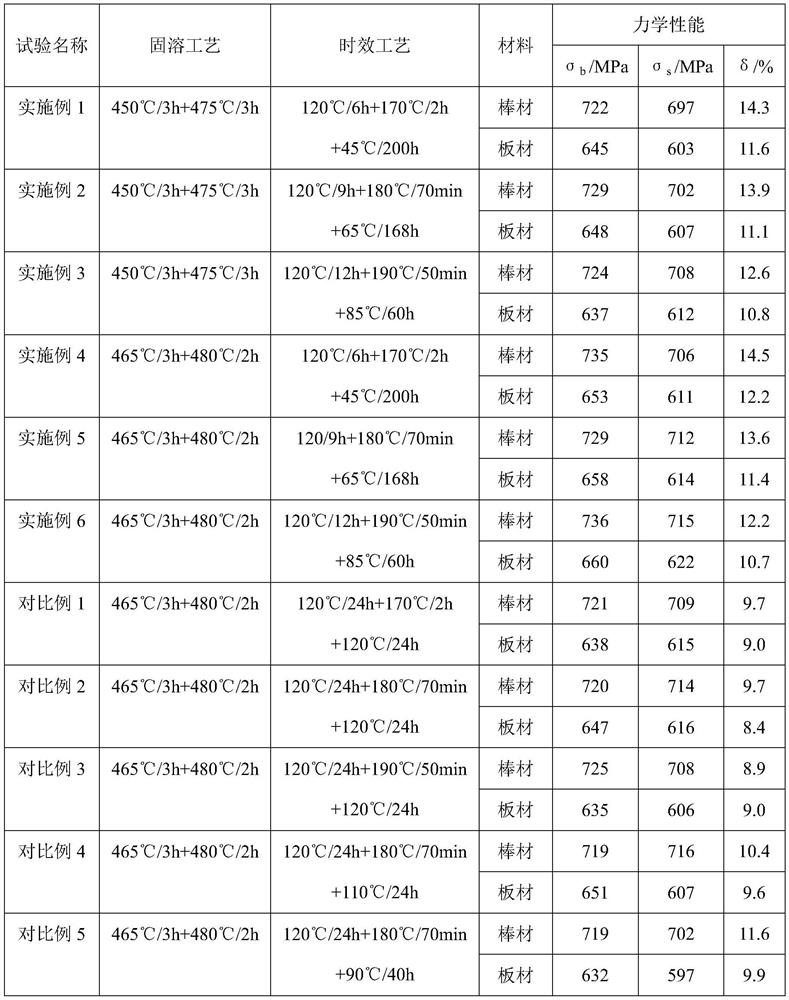

Embodiment 1

[0052]Example 1: Two specifications of extruded materials are first-level solid solution: heat preservation at 450° C. for 3 hours. Secondary solid solution: raise the temperature to 475°C for 3 hours in half an hour, and then quench in water. Under-aging pretreatment: the quenched material is kept at 120°C for 6 hours and then water-quenched to room temperature. Regression treatment: followed by holding at 170°C for 2 hours and then water quenching to room temperature. Low temperature re-aging treatment: followed by heat preservation at 45°C for 200 hours. After the heat treatment, the tensile test is carried out on the material, and the tensile strength, yield strength and elongation at break of the material are measured.

Embodiment 2

[0053] Example 2: two specifications of extruded material primary solid solution: heat preservation at 450°C for 3 hours. Secondary solid solution: raise the temperature to 475°C for 3 hours in half an hour, and then quench in water. Under-aging pretreatment: the quenched material is kept at 120°C for 9 hours and then water-quenched to room temperature. Regression treatment: followed by holding at 180°C for 70 minutes and then water quenching to room temperature. Low temperature re-aging treatment: followed by heat preservation at 65°C for 168 hours. After the heat treatment, the tensile test is carried out on the material, and the tensile strength, yield strength and elongation at break of the material are measured.

Embodiment 3

[0054] Example 3: First-level solid solution of two specifications of extruded materials: heat preservation at 450° C. for 3 hours. Secondary solid solution: raise the temperature to 475°C for 3 hours in half an hour, and then quench in water. Under-aging pretreatment: the quenched material is kept at 120°C for 12 hours and then water-quenched to room temperature. Regression treatment: followed by holding at 190°C for 50 minutes and then water quenching to room temperature. Low temperature re-aging treatment: followed by heat preservation at 85°C for 60 hours. After the heat treatment, the tensile test is carried out on the material, and the tensile strength, yield strength and elongation at break of the material are measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com