Crystal diameter control method for Czochralski silicon single crystal growth process

A technology of growth process and control method, which is applied in the field of crystal diameter control in the growth process of Czochralski silicon single crystal, can solve the problems of low yield, fluctuation of pulling speed, decline of crystal quality, etc., to achieve reasonable and accurate judgment and shorten the response. Time lag, not easy to effect the large fluctuation of crystal diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

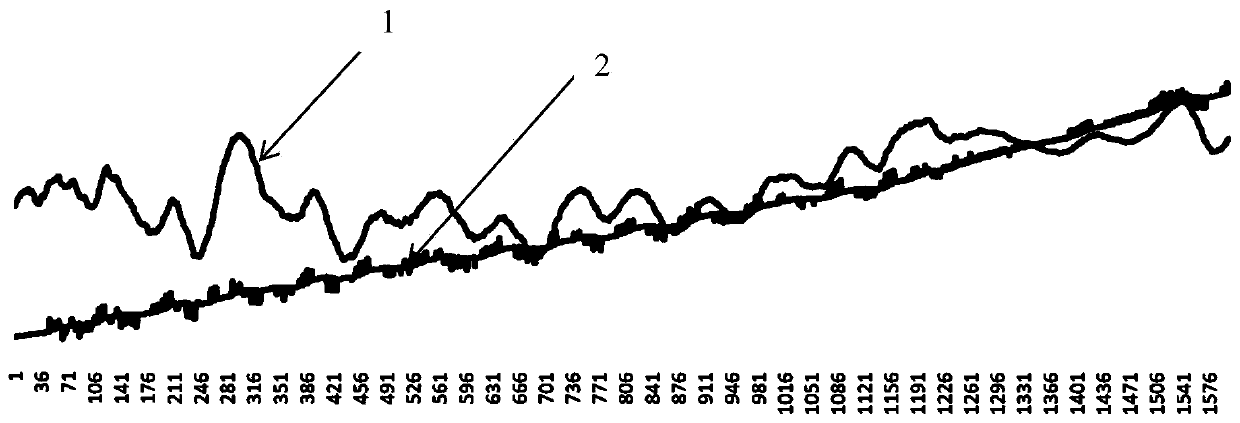

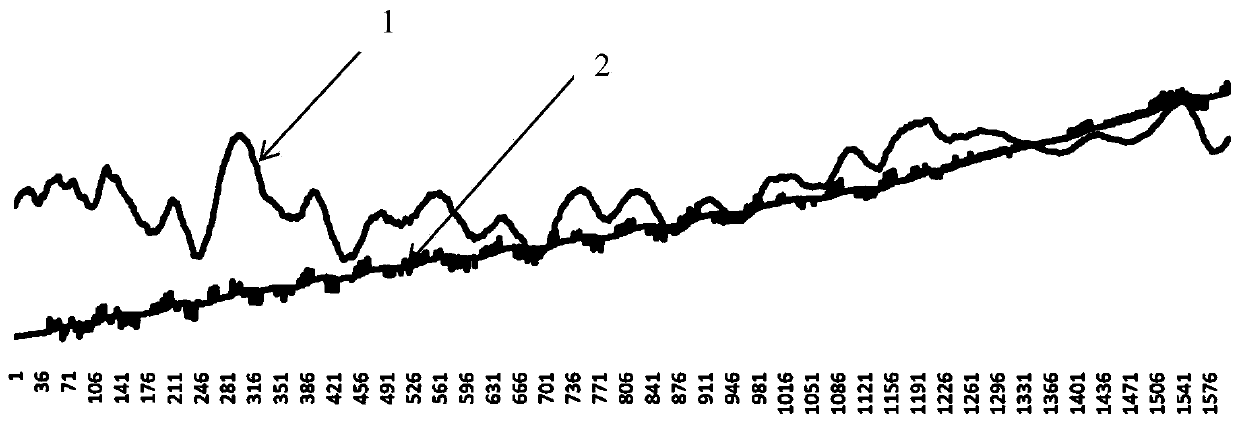

[0047] Use a 24-inch thermal field to grow crystals with a diameter of 210mm, and the loading capacity is 120kg. After the steps of seeding, shouldering and shoulder turning, the crystal enters the equal-diameter growth stage. In the initial stage of crystal isometric growth, there is a large deviation between the set diameter and the target diameter, and the set growth rate and the actual growth rate. When the equal-diameter length of the crystal reaches 100mm, the actual diameter of the crystal is 210.8mm, and the deviation is less than 1mm; the crystal average The growth rate is 33.4-33.8mm / hr, the target growth rate is 35mm / hr, the deviation is less than 2mm / hr, and it is maintained for 15 minutes, and the set point of the thermal field temperature is constant for 20 minutes. It is determined that the diameter control method of the present invention can be implemented.

[0048] To implement the diameter control method of the present invention, the crystal pulling speed is ...

Embodiment 2

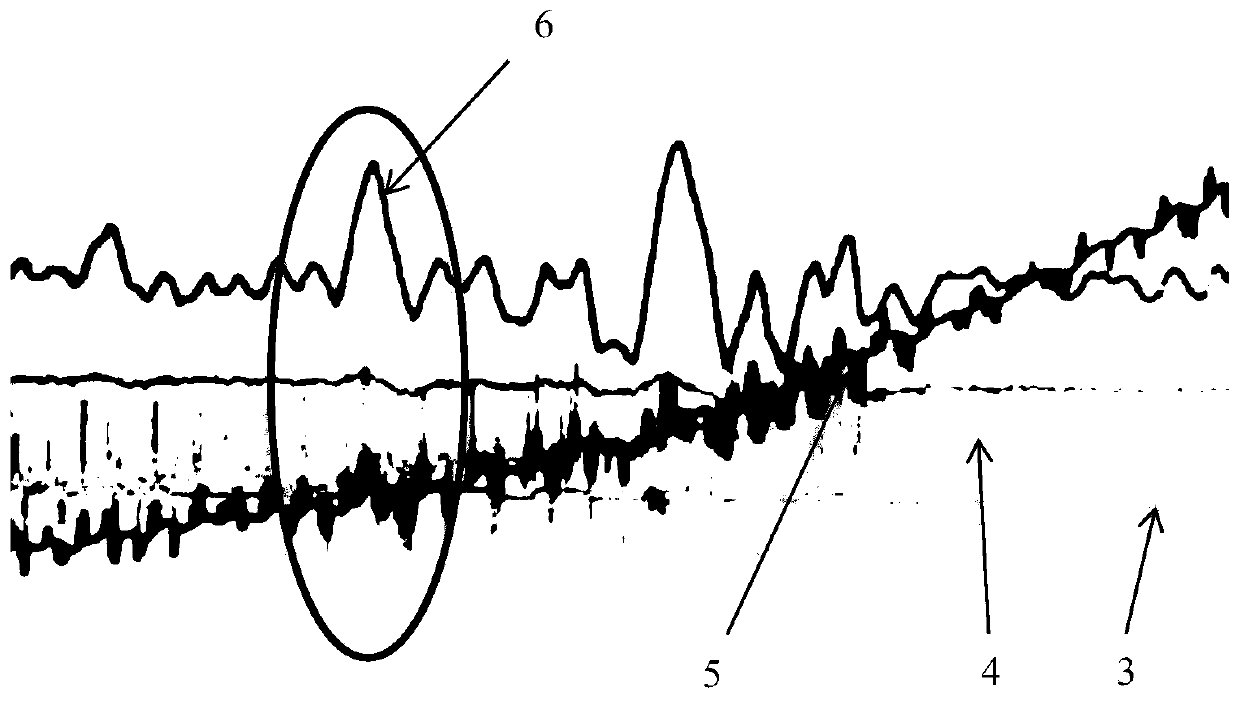

[0077] Embodiment 2: Example of control of thermal field temperature

[0078] Use a 24-inch thermal field to grow crystals with a diameter of 210mm, and the loading capacity is 120kg. After the steps of seeding, shouldering and shoulder turning, the crystal enters the equal-diameter growth stage. In the initial stage of crystal isometric growth, there is a large deviation between the set diameter and the target diameter, and the set growth rate and the actual growth rate. When the equal-diameter length of the crystal reaches 100mm, the actual diameter of the crystal is 210.8mm, and the deviation is less than 1mm; the crystal average The growth rate is 33.4-33.8mm / hr, the target growth rate is 35mm / hr, the deviation is less than 2mm / hr, and it is maintained for 15 minutes, and the set point of the thermal field temperature is constant for 20 minutes. It is determined that the diameter control method of the present invention can be implemented.

[0079] To implement the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com