Polymeric dispersing agent for textile dyes and preparation method of polymeric dispersing agent

A technology for polymer dispersants and textile dyes, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of changing dispersing effect of disperse dyes, damage of dye/dispersant system, failure to maintain stability, etc., so as to improve thermal stability , to avoid the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation material of this textile dyestuff macromolecule dispersant is as follows:

[0025] 4kg titanium sulfate, 0.5kg methyl alcohol, 4kg acrylic acid, 10kg butyl methacrylate, 1kg initiator, 0.3kg stearamide and 0.3kg higher alcohol, wherein, higher alcohol is the detergent alcohol of 12 carbon atoms, and initiator is Benzoyl peroxide.

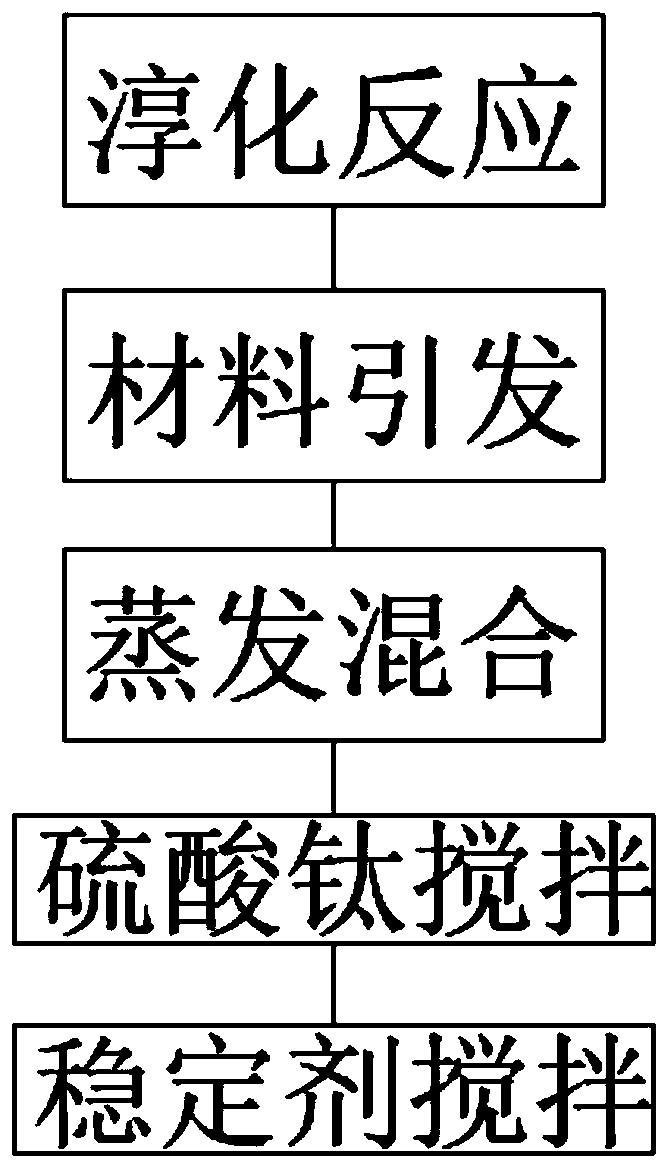

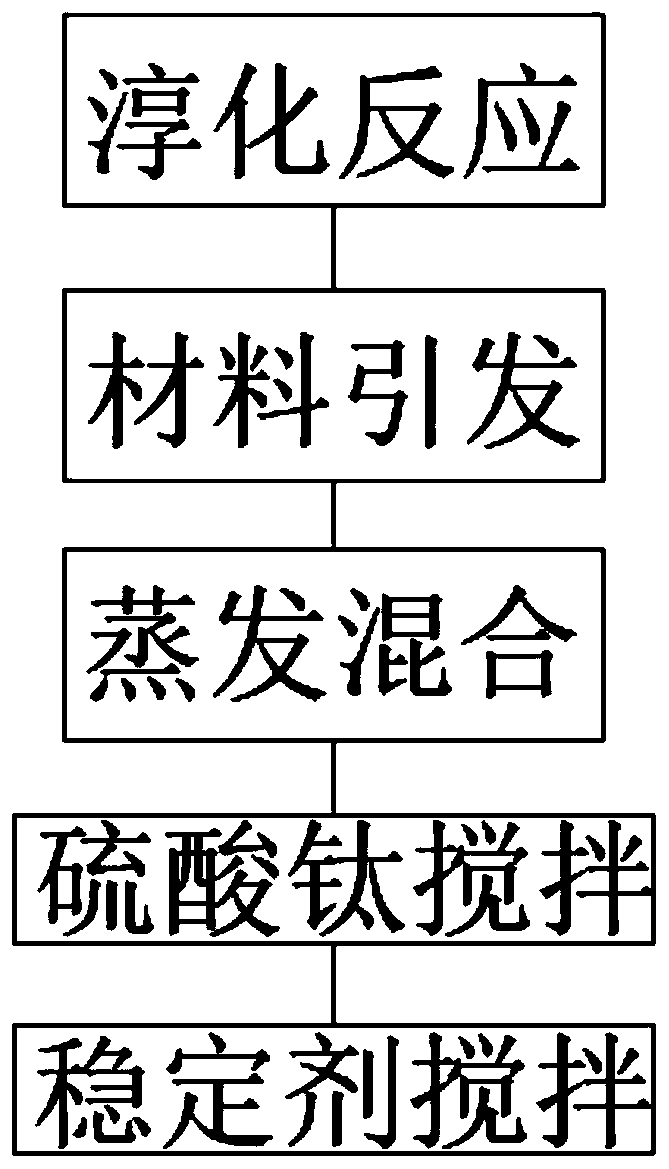

[0026] The preparation method of this textile dyestuff polymer dispersant is as follows:

[0027] Step 1: Add 10kg of butyl methacrylate into the reactor at 60°C, then pour 0.5kg of methanol solution from the funnel into the reactor to mix with butyl methacrylate;

[0028] Step 2: Mix 4 kg of acrylic acid and 1 kg of butyl methacrylate into another dropping funnel, add an initiator, and react for 2 hours;

[0029] Step 3: Evaporating the reacted substance to obtain a solid substance, adding the solid substance to the reactor and adding 20 kg of water to form an aqueous solution;

Embodiment 2

[0034] The preparation material of this textile dyestuff macromolecule dispersant is as follows:

[0035] 5kg titanium sulfate, 1kg methyl alcohol, 5kg acrylic acid, 20kg butyl methacrylate, 2kg initiator, 0.5kg stearamide and 0.5kg higher alcohol, wherein, higher alcohol is the detergent alcohol of 12 carbon atoms, and initiator is super Benzoyl Oxide.

[0036] The preparation method of this textile dyestuff polymer dispersant is as follows:

[0037] Step 1: Add 20kg of butyl methacrylate into the reactor at 70°C, then pour 1kg of methanol solution from the funnel into the reactor to mix with butyl methacrylate;

[0038] Step 2: Mix 5 kg of acrylic acid and 1 kg of butyl methacrylate into another dropping funnel, add an initiator, and react for 2 hours;

[0039] Step 3: Evaporating the reacted substance to obtain a solid substance, adding the solid substance to the reactor and adding 40 kg of water to form an aqueous solution;

[0040] Step 4: Add 5kg of titanium sulfate t...

Embodiment 3

[0044] The preparation material of this textile dyestuff macromolecule dispersant is as follows:

[0045] 6kg titanium sulfate, 1.5kg methyl alcohol, 6kg acrylic acid, 30kg butyl methacrylate, 3kg initiator, 0.8kg stearamide and 0.8kg higher alcohol, wherein, higher alcohol is the detergent alcohol of 12 carbon atoms, and initiator is Benzoyl peroxide.

[0046] The preparation method of this textile dyestuff polymer dispersant is as follows:

[0047] Step 1: Add 30kg of butyl methacrylate into the 80°C reactor, then pour 1.5kg of methanol solution from the funnel into the reactor to mix with butyl methacrylate;

[0048] Step 2: Mix 6 kg of acrylic acid and 1 kg of butyl methacrylate into another dropping funnel, add an initiator, and react for 2 hours;

[0049] Step 3: Evaporating the reacted substance to obtain a solid substance, adding the solid substance to the reactor and adding 60 kg of water to form an aqueous solution;

[0050] Step 4: Add 6kg of titanium sulfate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com