A gas explosion-proof partition for underground

A partition and gas technology, applied in the directions of dust prevention, fire prevention, mining equipment, etc., can solve the problems of poor anti-explosion and anti-shock effect, inconvenient operation, simple structure, etc., to improve interchangeability and maintenance efficiency , Increase the effect of aramid fiber guard plate, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

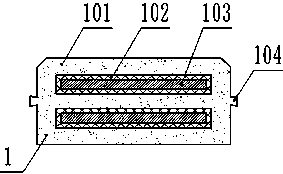

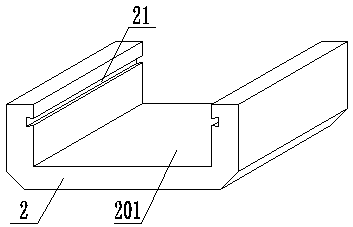

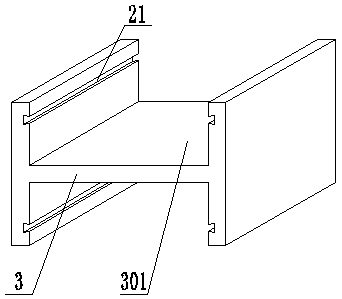

[0041] The invention provides a gas explosion-proof partition for underground, such as Figure 1 to Figure 11 shown. The gas explosion-proof partition for downhole includes an explosion-proof partition 9 and several groups of unit bodies, and the explosion-proof partition 9 is provided with an explosion-proof cavity for placing the unit body, and each group of unit bodies includes a base and is equipped with the base. The basic micro-element structure 1, in this embodiment, the explosion-proof partition 9 and the protective plate are made of impact-resistant and fatigue-resistant aramid fiber guard, and the explosion-proof partition 9 is composed of six protective plates, respectively The upper guard plate 901, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com