Oiling machine output pipe emergency cutting protection device and oiling machine

A protection device and fuel dispenser technology, which is applied to cocks including cut-off devices, liquid distribution, conveying or transfer devices, valve devices, etc., and can solve the problems of pipe tearing of fuel guns, pulling down fuel dispensers, gasoline injection accidents, etc. problems, to achieve the effect of convenient maintenance and simple linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

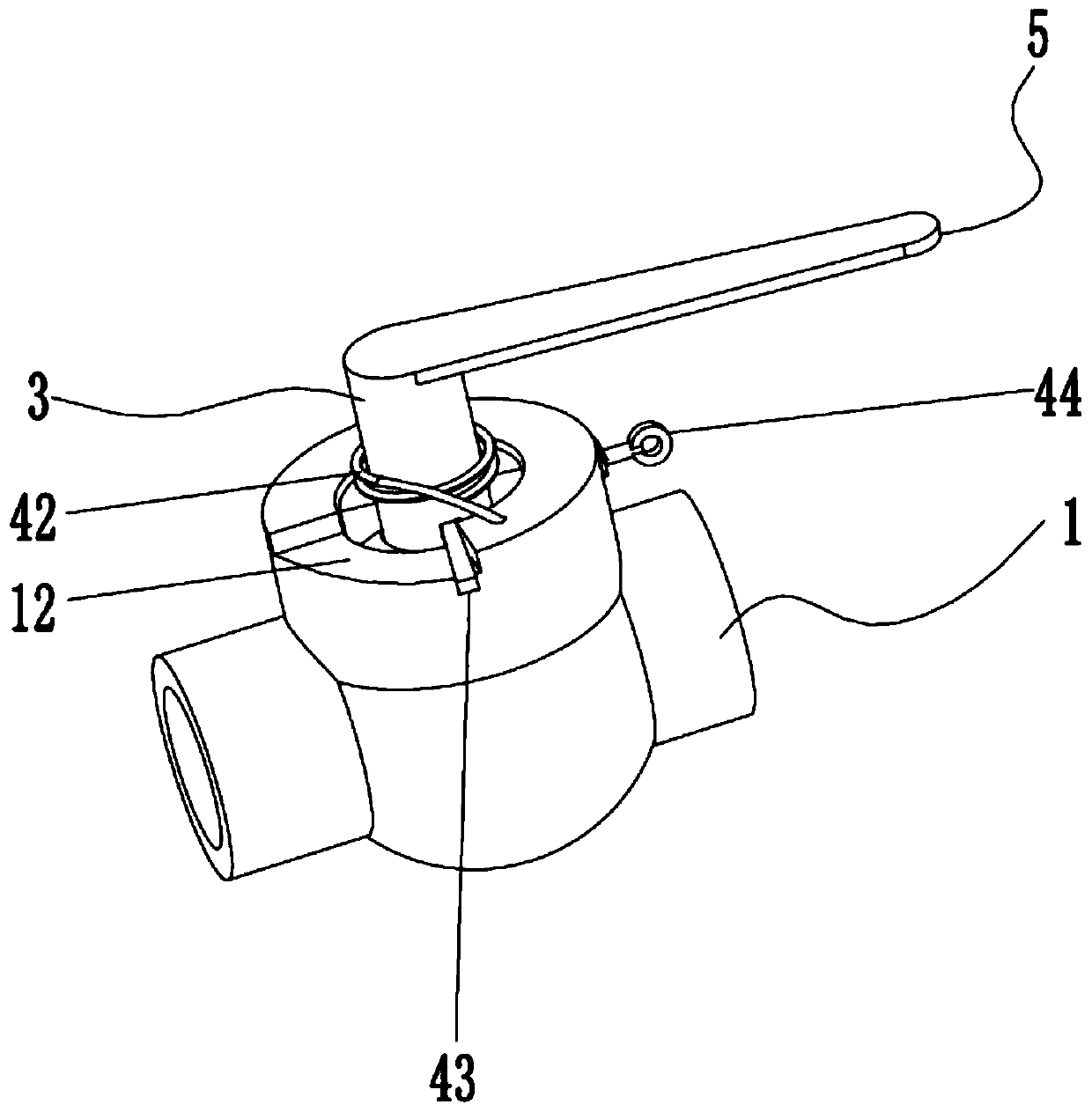

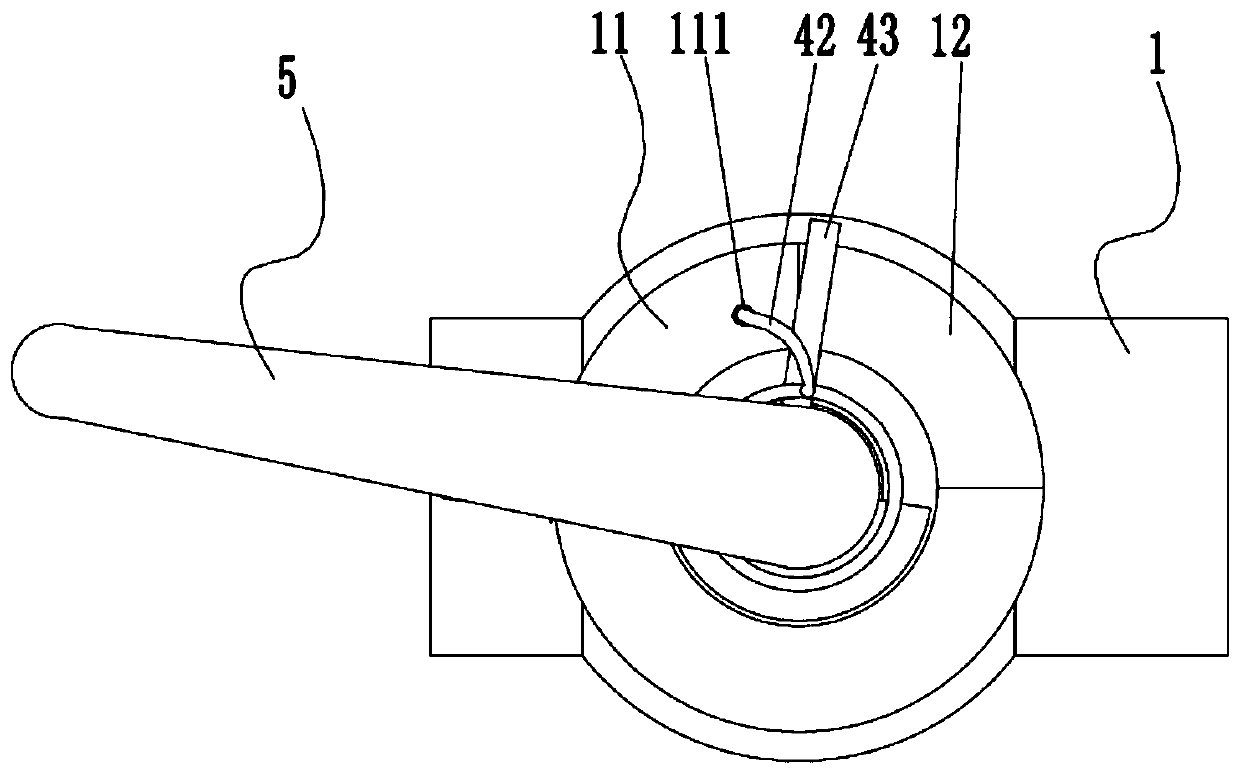

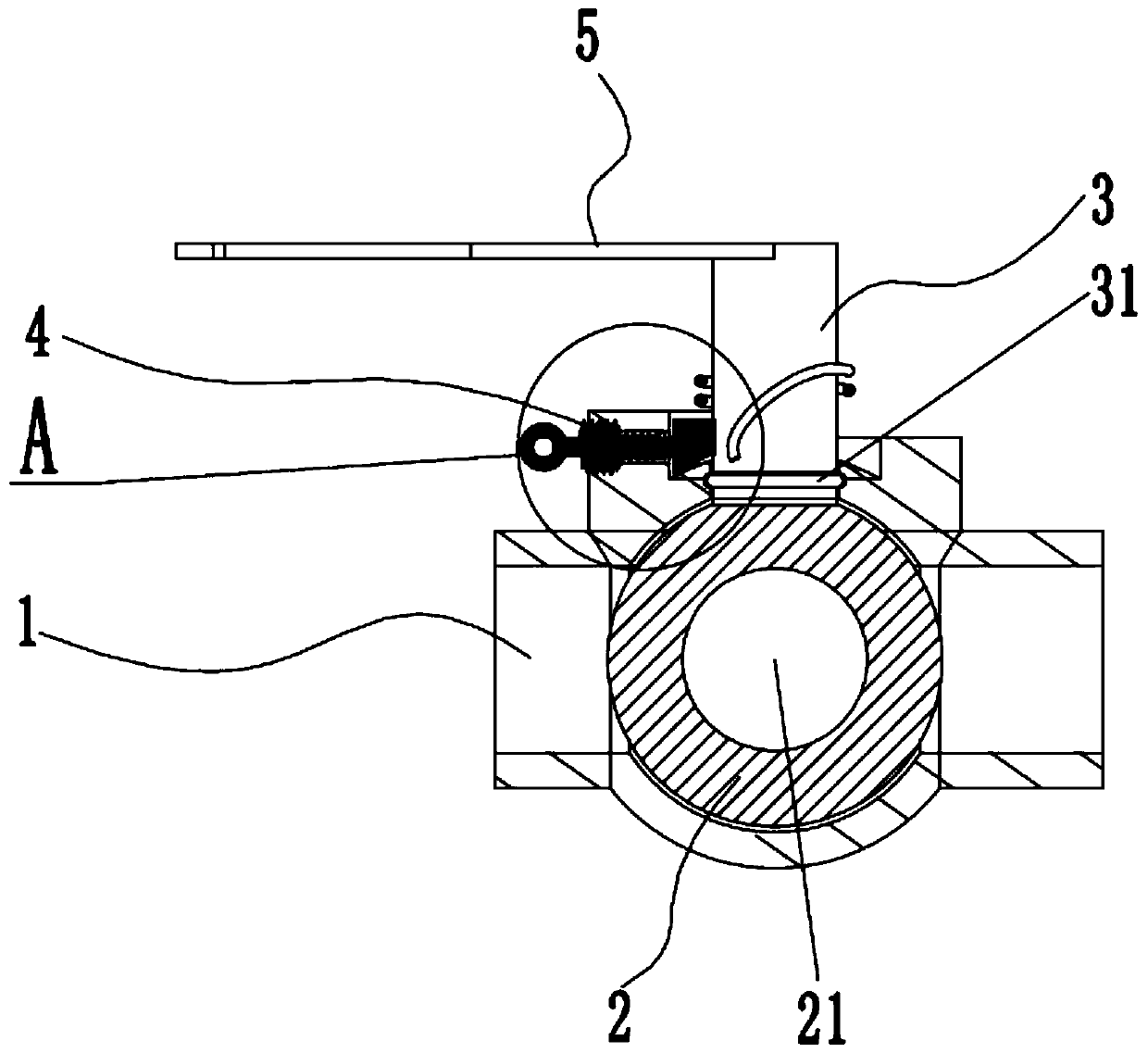

[0023] like Figures 1 to 8 As shown in one of them, the device 6 of the present invention is arranged on the oil delivery pipeline 8 of the fuel dispenser 7, and the oil delivery pipeline 8 is connected with the oil tank 9, and it includes a ball valve body 1, a valve ball 2, a valve stem 3 and a handle 5. The valve ball 2 is rotatably connected in the ball valve body 1, and the middle part of the upper end of the ball valve body 1 is provided with a connecting seat 11, and one end of the valve stem 3 is rotatably passed through the connecting seat 11 and connected with the ball valve body 1. The valve ball 2 is connected, and the rotation of the valve stem 3 drives the valve ball 2 to rotate, so that the channel 21 of the valve ball 2 is aligned or staggered with the flow channel of the valve body, so as to realize the passage or stop of the ball valve body 1. The handle 5 is connected to the other end of the valve stem 3. The device also includes a locking mechanism 4 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com