cold storage ice bag

An ice pack and cold storage technology, which is applied to household refrigeration devices, packaging, packaging items, etc., can solve the problems of short cold storage time, low latent heat of phase transition, leakage, etc., to avoid thermal damage, prolong refrigeration time, and high latent heat of phase transition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

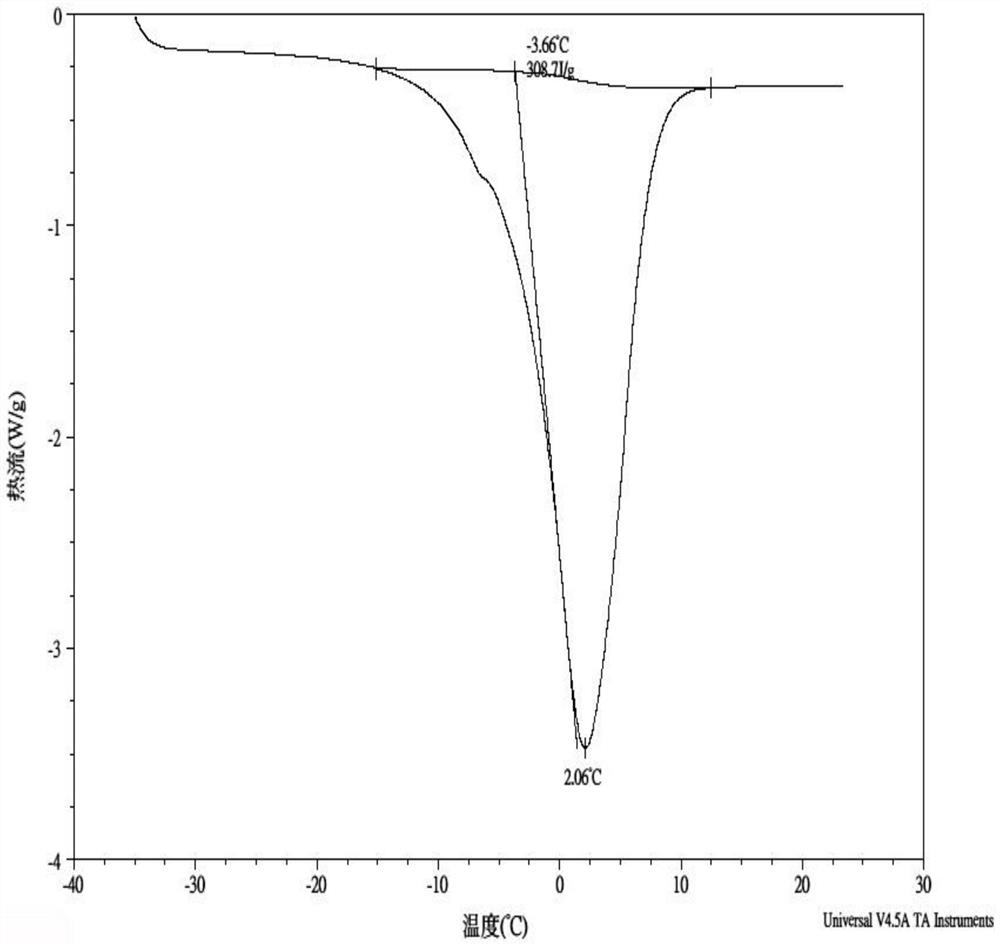

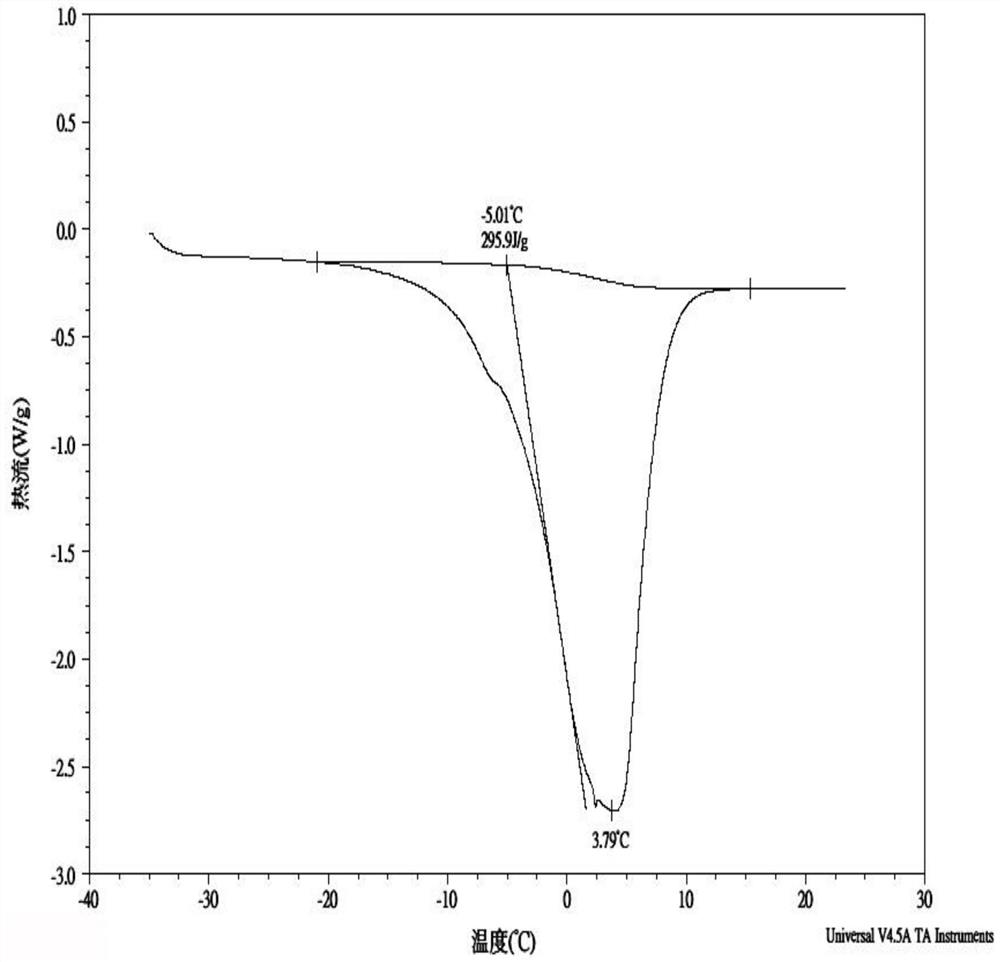

[0044] In order to further optimize the above-mentioned technical scheme, the preparation method of the cold storage agent, the specific steps are as follows;

[0045] S1: Add 2-3 parts of konjac powder and 1-3 parts of polyvinyl alcohol to 90 parts of water, heat to 80°C, and keep stirring for 60 minutes to fully swell to obtain mixed solution A;

[0046] S2: add 2-5 parts of potassium nitrate and 1-3 parts of sodium chloride to 5 parts of water, heat to 40°C, and keep stirring to fully dissolve to obtain mixed solution B;

[0047] S3: add 1-3 parts of borax to 5 parts of water, heat to 40°C, and keep stirring to fully dissolve to obtain a mixed solution C;

[0048] S4: Add the mixed solution B to the mixed solution A, and keep stirring, add the mixed solution C after 3-5 minutes, stir for another 3-5 minutes, cool to room temperature to obtain the cooling agent.

Embodiment 1

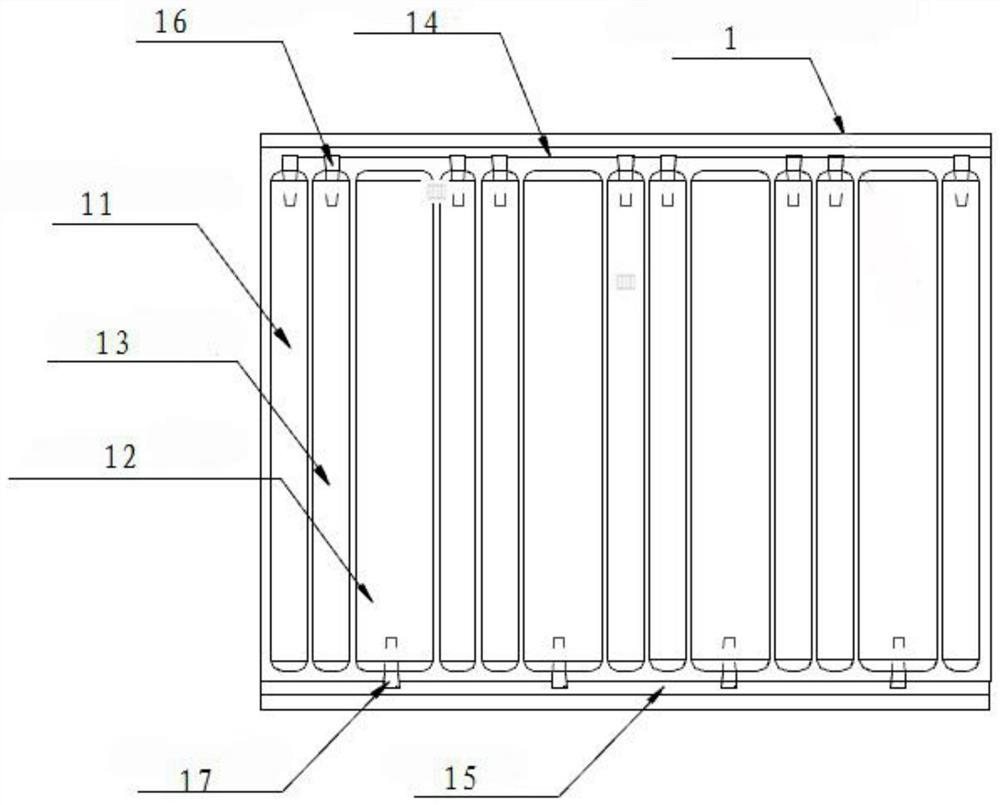

[0050] Combined with the manual Figure 1-2 , the embodiment of the present invention discloses a cold storage ice bag, including an outer membrane 1, on which are formed a liquid storage chamber 11 for storing cold storage agent, an air storage chamber 12 for storing air, a hollow cavity 13, and a general liquid inlet channel 14 , the main inlet channel 15, the one-way liquid inlet branch channel 16 and the one-way inlet branch channel 17, the liquid inlet main channel 14 and the air inlet main channel 15 are respectively laterally located at the two ends of the outer membrane 1, the liquid storage chamber 11, the hollow Both the cavity 13 and the air storage chamber 12 are multiple, and they are arranged longitudinally between the liquid inlet main channel 14 and the air intake main channel 15, and the two sides of each hollow cavity 13 are respectively connected in parallel with the liquid storage room 11 and the gas storage room. chamber 12, each liquid storage chamber 11 ...

Embodiment 2

[0059] Combined with the manual figure 1 with instructions attached image 3 , the embodiment of the present invention discloses a cold storage ice bag, including an outer membrane 1, on which are formed a liquid storage chamber 11 for storing cold storage agent, an air storage chamber 12 for storing air, a hollow cavity 13, and a general liquid inlet channel 14 , the main inlet channel 15, the one-way liquid inlet branch channel 16 and the one-way inlet branch channel 17, the liquid inlet main channel 14 and the air inlet main channel 15 are respectively laterally located at the two ends of the outer membrane 1, the liquid storage chamber 11, the hollow Both the cavity 13 and the air storage chamber 12 are multiple, and they are arranged longitudinally between the liquid inlet main channel 14 and the air intake main channel 15, and the two sides of each hollow cavity 13 are respectively connected in parallel with the liquid storage room 11 and the gas storage room. Chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com