Thermally tuned frequency selective surface based on BST film and processing technology

A frequency selective surface and thermal tuning technology, applied in the direction of electrical components, circuits, antennas, etc., can solve the problems of non-shielding, dichroic sub-reflectors cannot be dynamically adjusted, and spatial filters are difficult to meet actual needs, etc., to achieve the realization of intermediary Electrically Tunable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

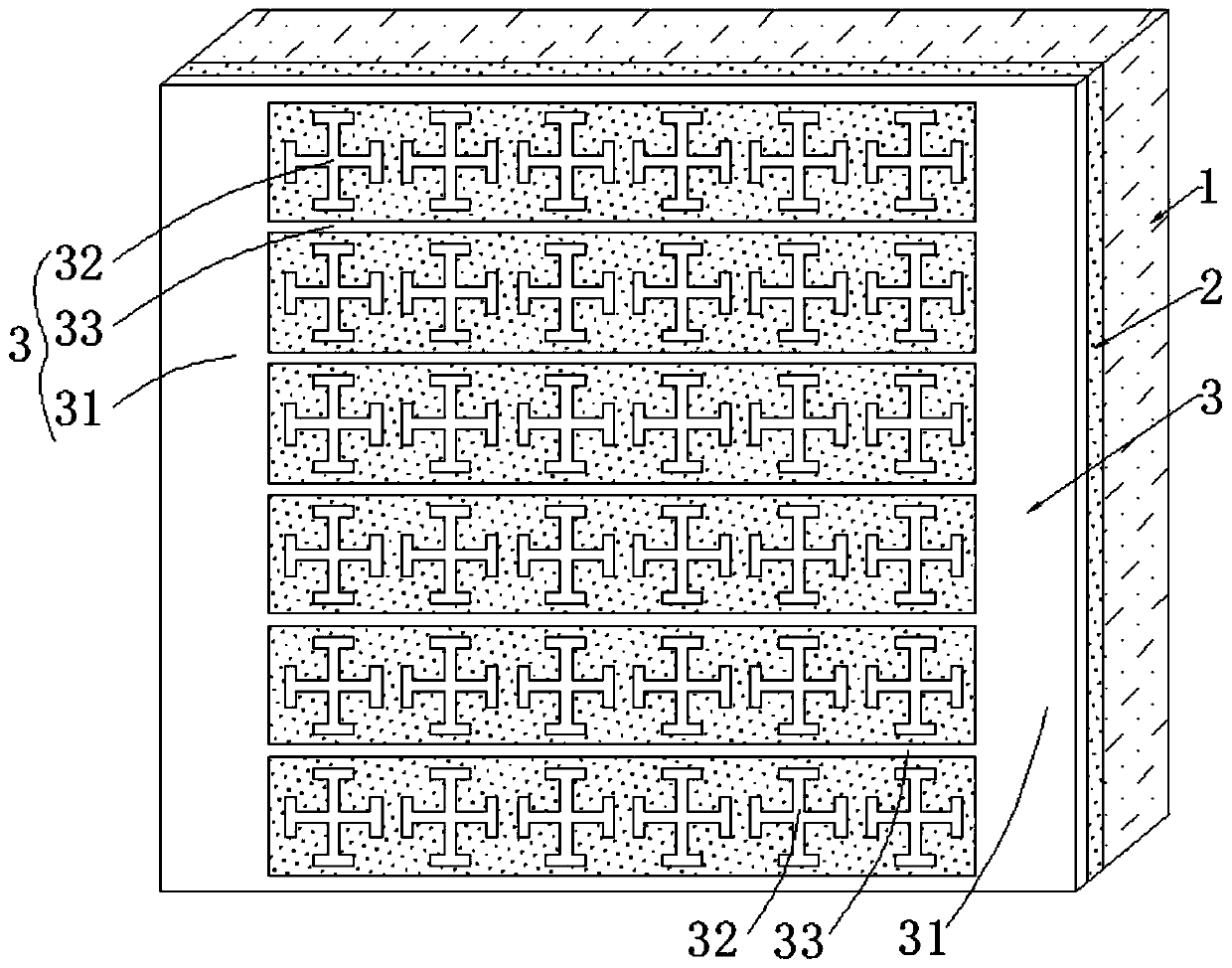

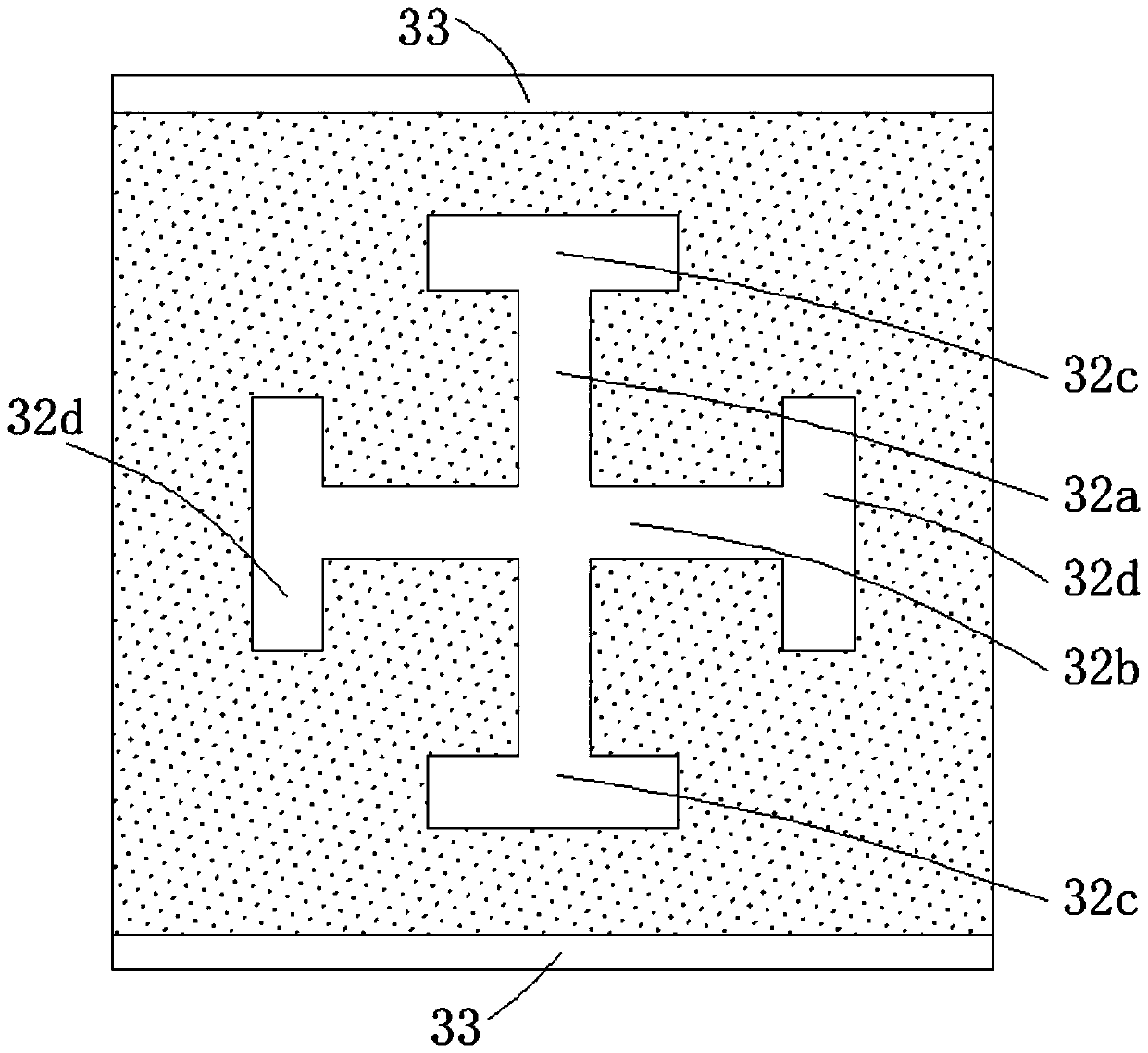

[0033] like figure 1 and figure 2 As shown, a thermally tuned frequency selective surface based on BST thin film includes a base layer 1, an intermediate dielectric layer 2 and a frequency selective surface metal layer 3 arranged in close contact from bottom to top, and the frequency selective surface metal layer 3 includes The electrodes 31 arranged on both sides and a plurality of FSS structural units 32 arranged between the two electrodes 31, when used, the electrodes 31 are fixed by a flat conductive clip and connected to the positive and negative poles of the power supply, between the two electrodes 31 A micron-scale electric heating unit 33 is also connected between them, and the plurality of FSS structural units 32 are arranged at equal intervals in the electric heating unit 33 to form a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com