Rapid debugging system and method of brushless electric machine

A brushless motor and debugging system technology, applied in the control system, electronic commutation motor control, electrical components, etc., can solve the problems of large mechanical structure size and weight, difficult inspection of motion assembly accuracy, and affecting the process of equipment development, etc. Achieve high safety, fast and convenient application, simple and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

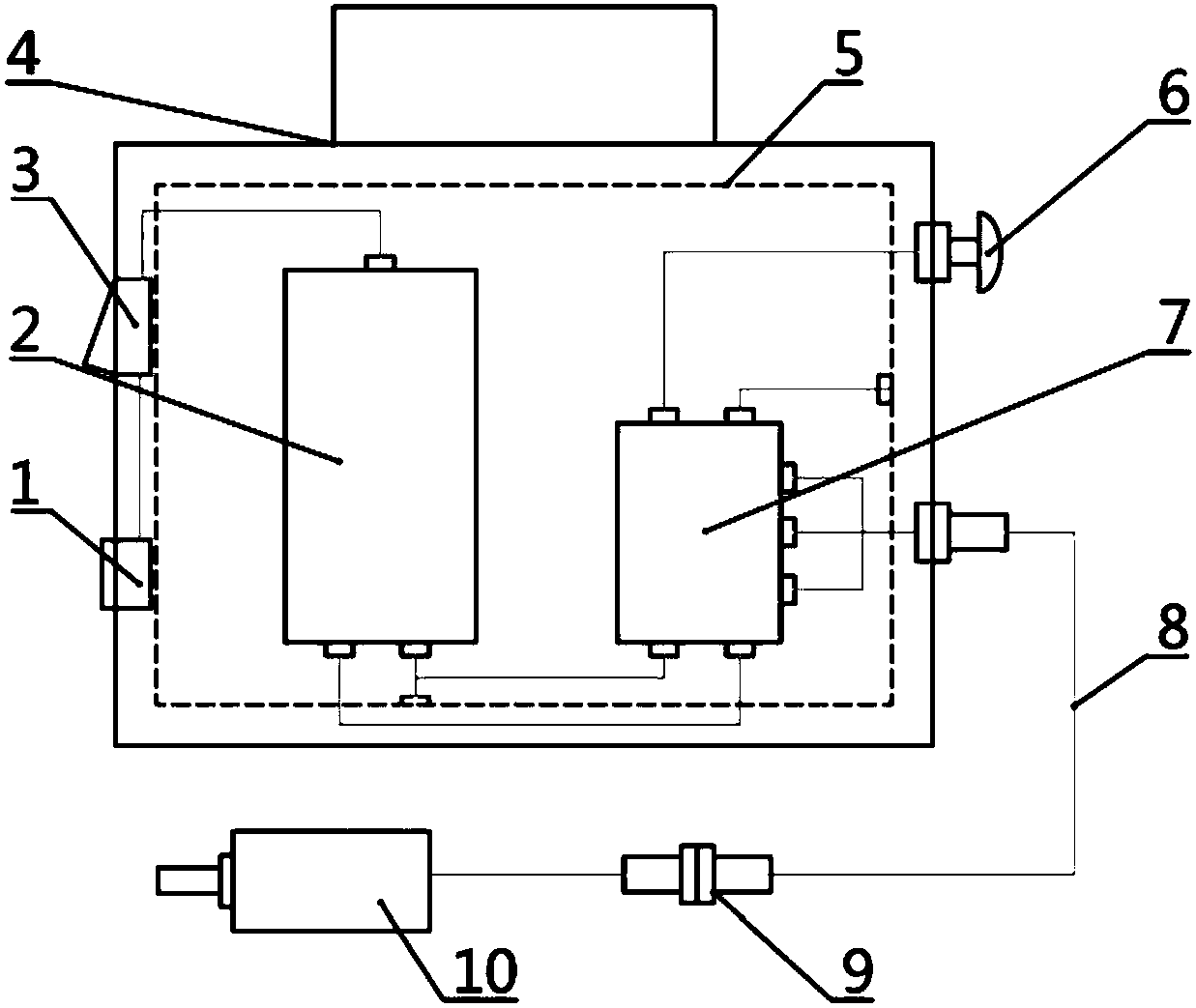

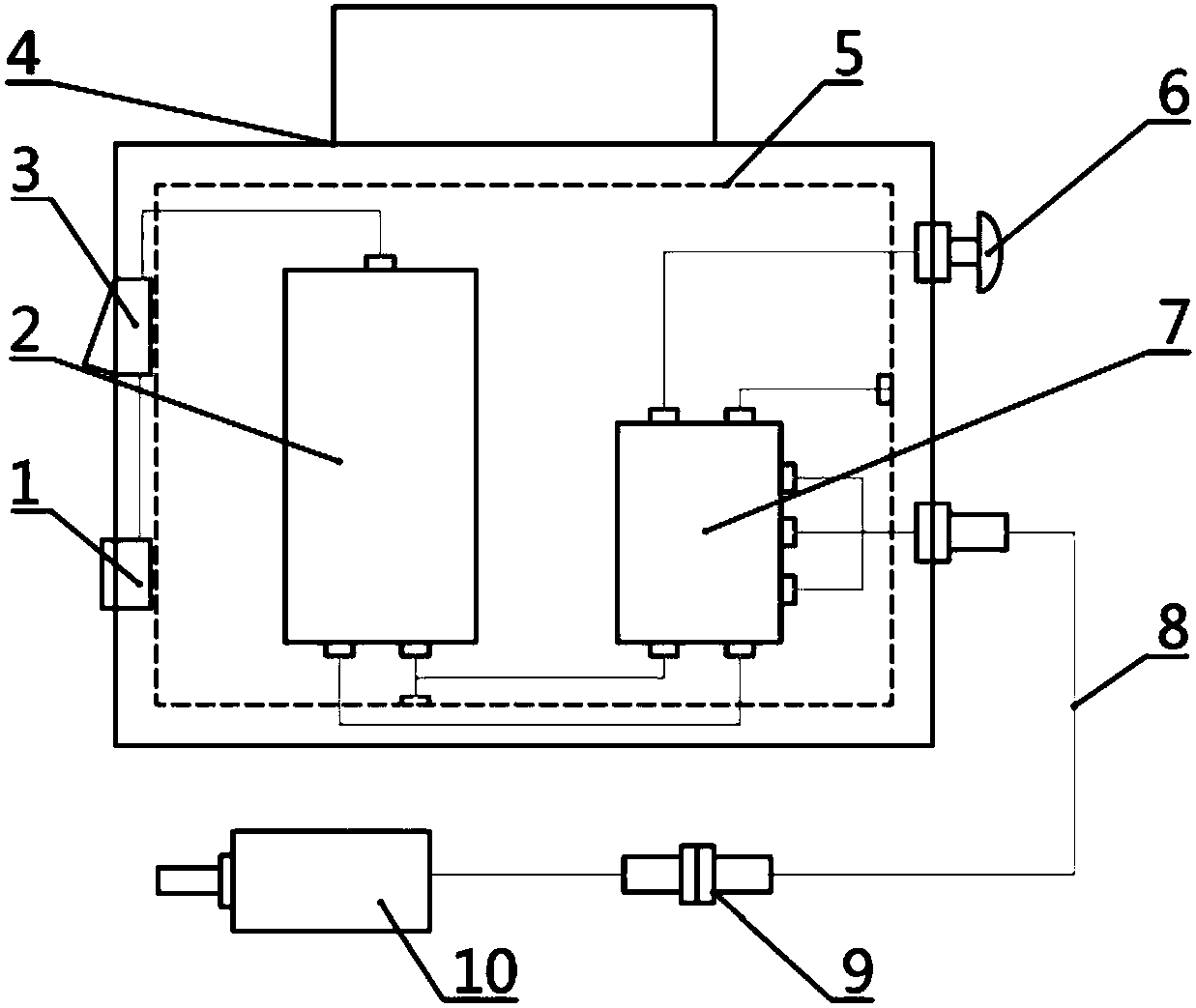

[0020] like figure 1 As shown, a brushless motor quick debugging device includes a power module 2, an electrical box 4, a driver 7 and a brushless motor 10, wherein the power module 2 and the driver 7 are fixedly installed in the electrical box 4, wherein the power module 2 The input terminal of the power supply is connected to the power switch 3 installed in the electrical box 4 and the power input socket 1, and the high-voltage DC output terminal of the power module 2 is connected to the high-voltage input terminal of the driver 7 to provide power for the motor power circuit of the driver 7 , the low-voltage DC output terminal of the power module 2 is respectively connected to the low-voltage control input terminal of the driver 7 and the tablet computer 5 installed on the front panel of the electrical box 4, and the low-voltage DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com