Straw baler applicable to thresher

A baler and thresher technology, applied in the field of straw balers, can solve the problems of poor work coordination, cumbersome work, easy damage of keys, etc., and achieve the effect of flexible use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

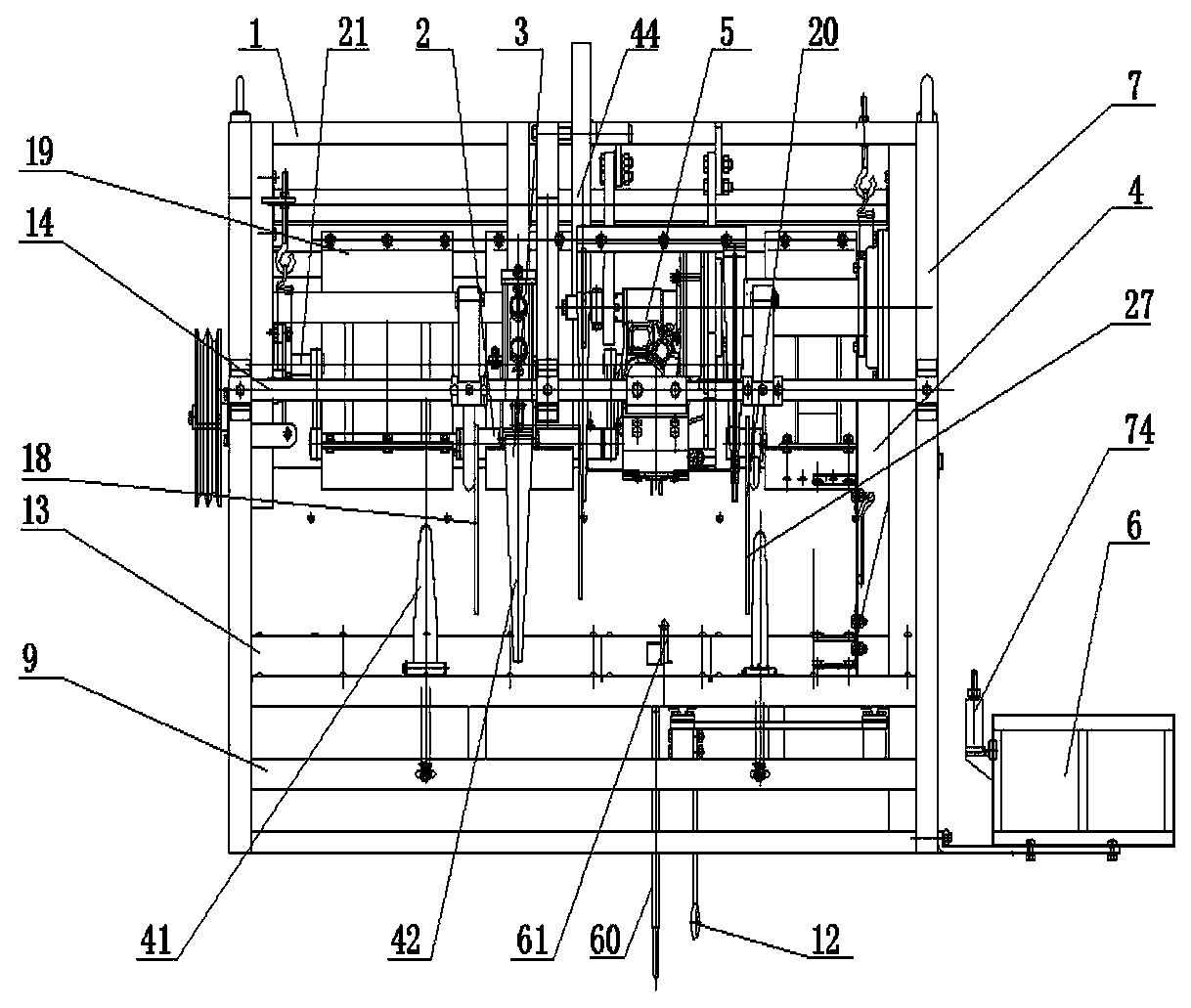

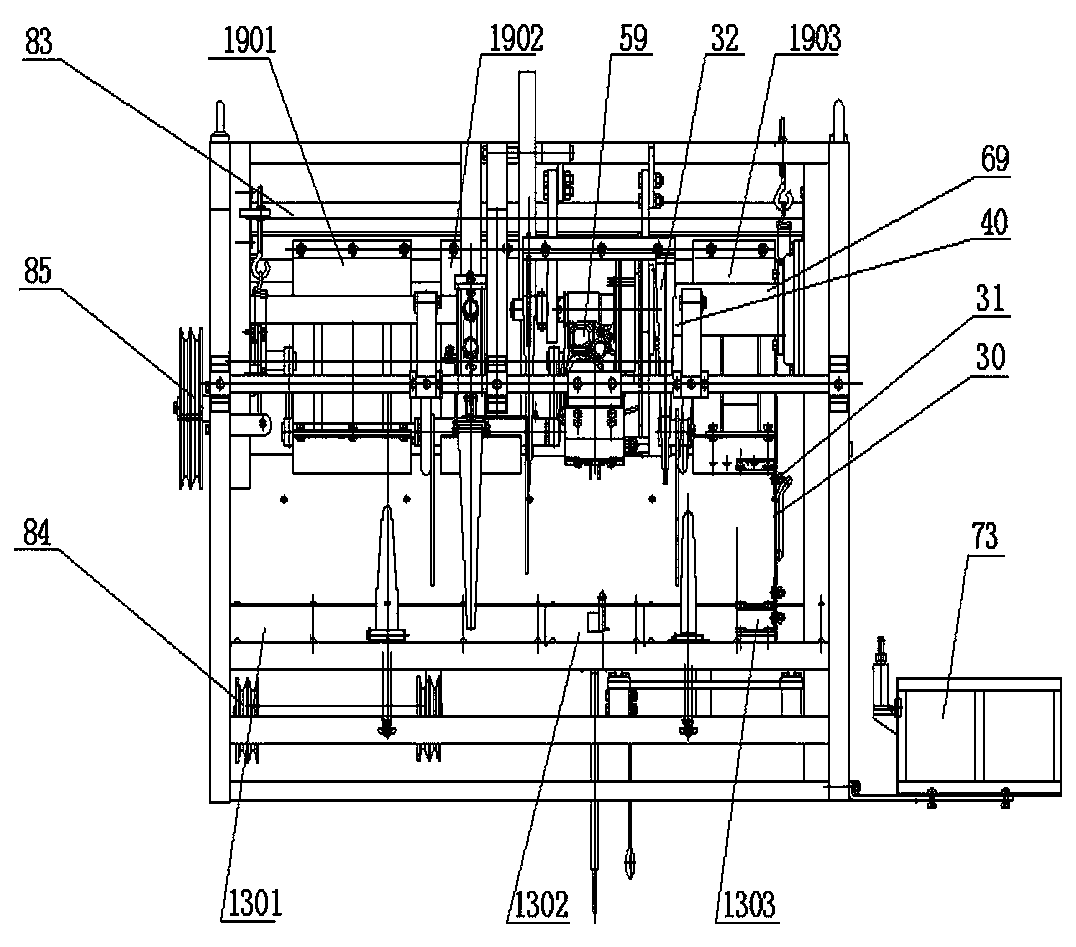

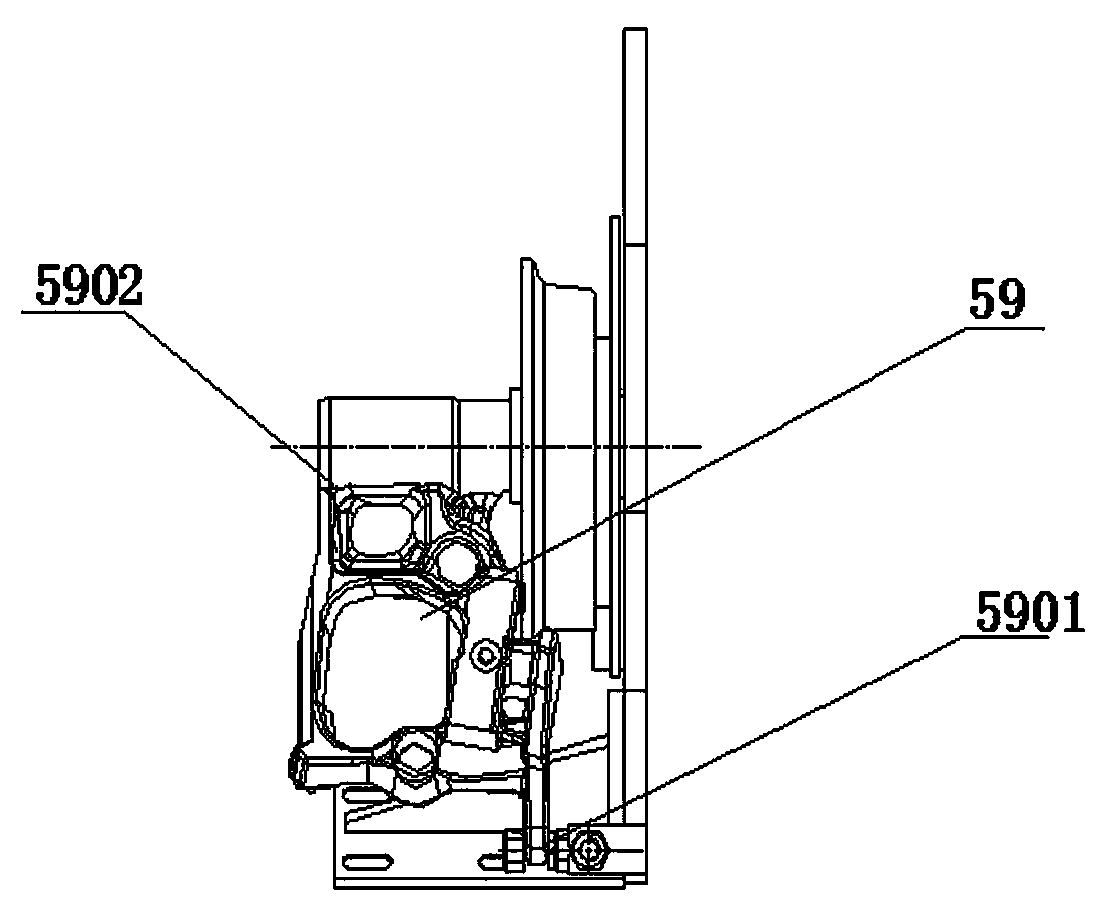

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20As shown, a straw baler suitable for a thresher includes a frame 1, a grass feeding mechanism 2, a grass outlet mechanism 3, a grass level control mechanism 4, a bundling mechanism 5, a rope storage mechanism 6 and a power input mechanism , the grass feeding mechanism 2 is arranged at the rear end of the vehicle frame 1, the grass discharging mechanism 3 is arranged at the front end of the vehicle frame 1, and the baling mechanism 5 is arranged between the grass feeding mechanism 2 and the grass discharging mechanism 3 Between, the grass level control mechanism 4 is set on the right end of the frame 1, located on the right side of the bundling mechanism 5, and the storage rope mechanism 6 is set on the ...

Embodiment 2

[0048] Such as figure 1 , figure 2 As shown, there is a certain distance between the head grass pressing plate 1901, the middle grass pressing plate 1902 and the root grass pressing plate 1903, leaving space for the grass feeding double fork 22 and the grass feeding single fork 27 activities. The double fork 22 and the grass-feeding single fork 27 are arranged at a certain angle, which is convenient for bringing the straw into the bundling position.

Embodiment 3

[0050] Such as figure 1 , figure 2 The power input mechanism includes a power shaft 83, an input drive pulley 84 and an input pulley 85. The power shaft 8383 is arranged inside the vehicle frame 1 through a bearing, and gears are arranged at both ends of the power shaft 83 to be connected with the vehicle. The gears on the side of the frame 1 are meshed with each other. The left side of the frame 1 is provided with an input pulley 85, and the bottom of the rear end of the frame 1 is provided with an input drive pulley 84. The center of the input pulley 85 is connected with the bearing through the bearing. The crankshaft 25 of the double-fork assembly 18 of grass feeding is connected. The crankshaft 25 is provided with a gear that meshes with the gear on the power shaft 83 . The left end of the input driving pulley 84 is connected with the input pulley 85 through a belt, and the right end of the input driving pulley 84 is connected with the threshing machine through a belt. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com