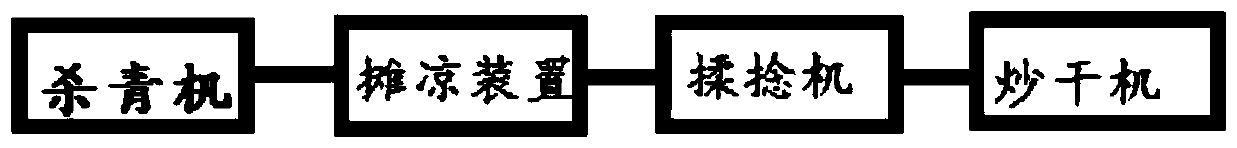

Processing technology and processing system of green tea product

A processing technology and processing system technology, which is applied in tea processing before extraction, etc., can solve problems such as the disappearance of fresh aroma and taste, reduce the yield of tea products, and the loss of dry matter of fresh tea, so as to avoid the loss of dry matter, Eliminate raw green odor, the effect of uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of processing technology of green tea product, comprises the following steps:

[0040] (1) Raw materials: fresh tea leaves of single bud, one bud and one leaf and one bud and two leaves, with a water content of 75wt%.

[0041] Raw material handling: Raw materials are not spread out and withered, and the storage time is ≤2h.

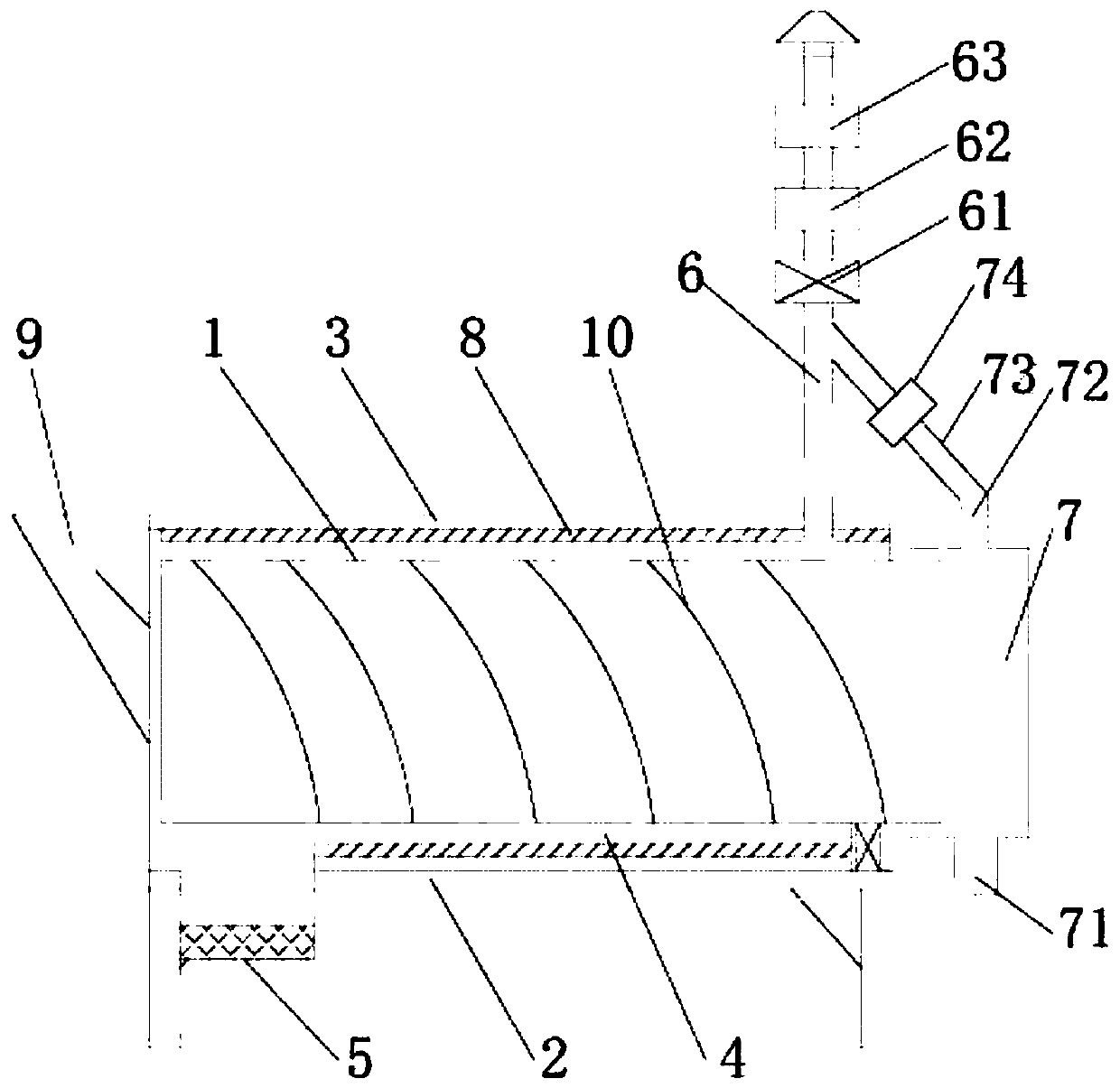

[0042] (2) Enzyme-fixing: adopt the green-fixing machine to directly carry out the green-fixing treatment without withering the raw materials, that is, the green-fixing leaves, spread cool, and the water content of the green-finishing leaves≤35wt%;

[0043] The model of the de-enzyming machine is a type 80 drum continuous de-enzyming machine, the de-enzyming temperature of the de-enzyming process is 200-280°C, and the de-enzyming temperature is the temperature of the de-enzyming cylinder of the de-enzyming machine; the de-enzyming process includes three stages of temperature-controlled de-enzyming Treatment: The amount of leaves thrown is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com