Iron powder impurity removal device

A technology of iron powder and transmission device, which is applied in the field of impurity removal, can solve the problems of damage to the transmission belt, difficult to clean, and reduce production efficiency, and achieves the effect of avoiding damage, avoiding damage and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

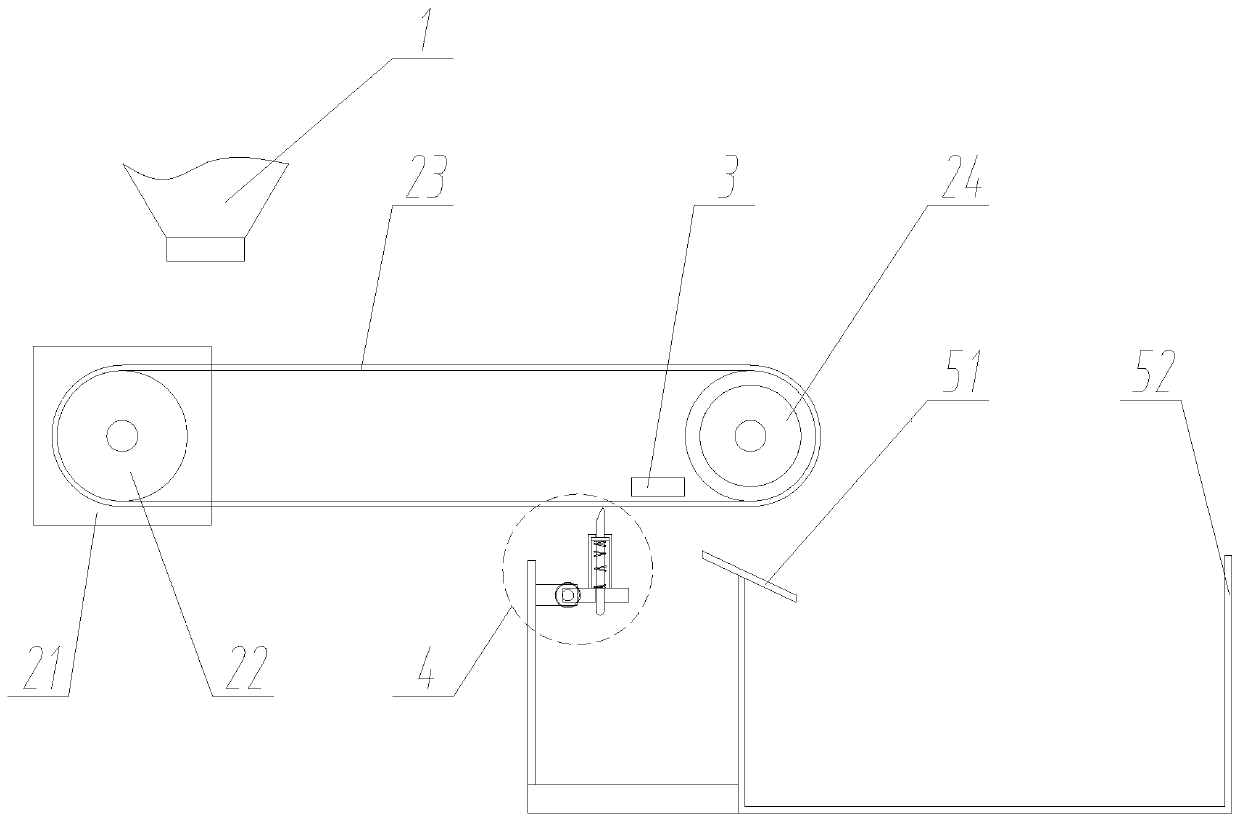

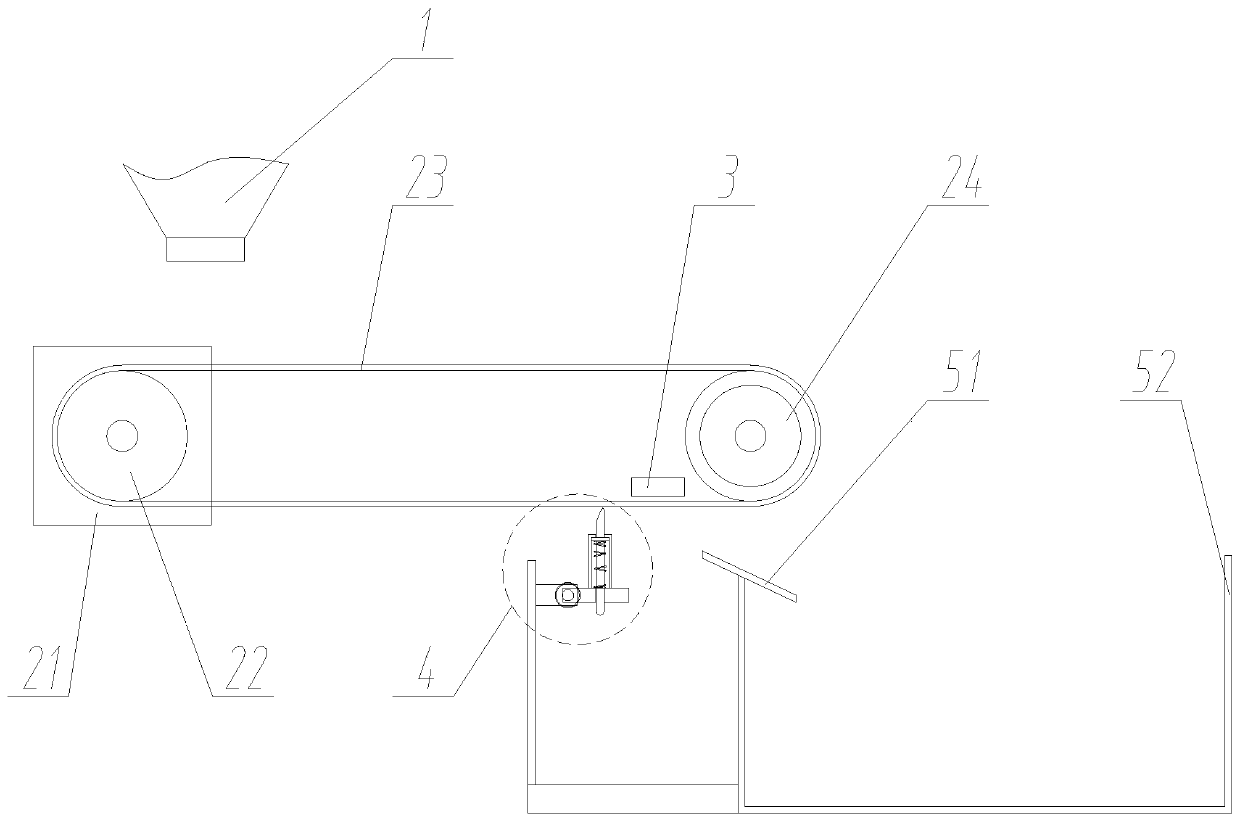

[0018] Such as figure 1 , figure 2 Shown, this iron powder impurity removal device comprises transmission device, strong magnet 3, impurity removal device 4 and collection box 52;

[0019] The transmission device includes a motor 21, a driving wheel 22 fixedly connected to the output end of the motor 21, and a driven wheel 24 positioned on the right side of the driving wheel 22, and a transmission belt wound around the outside of the driving wheel 22 and the driven wheel 24 23 connections;

[0020] A lower hopper 1 is arranged above the driving wheel 22, and an annular magnetic block is arranged on the outer side of the driven wheel 24;

[0021] The collection box 52 is located below the driven wheel 24;

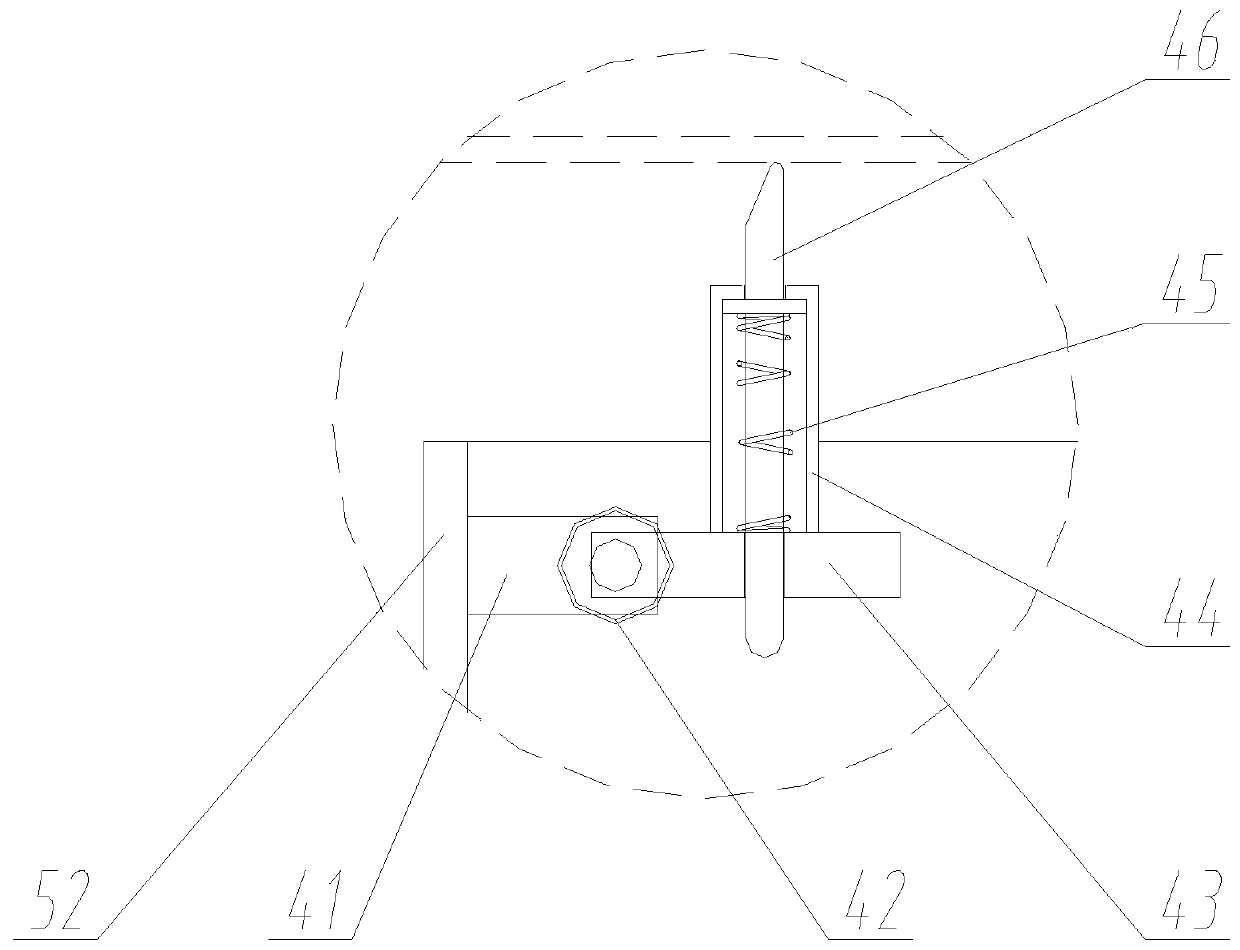

[0022] The scraper device 4 is located on the left side of the driven wheel 24, and includes a fixed block 41, a locking bar 42, a support rod 43, a sleeve 44, a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com