Automatic protection type sandstone sorting and collecting integration device for mechanical engineering

A mechanical engineering and automatic sorting technology, applied in the field of mechanical engineering, can solve the problems of large differences in the outer diameter of stones, general vibration screening effect, and difficult communication between users, so as to facilitate effective communication, reduce noise transmission, and use safely convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

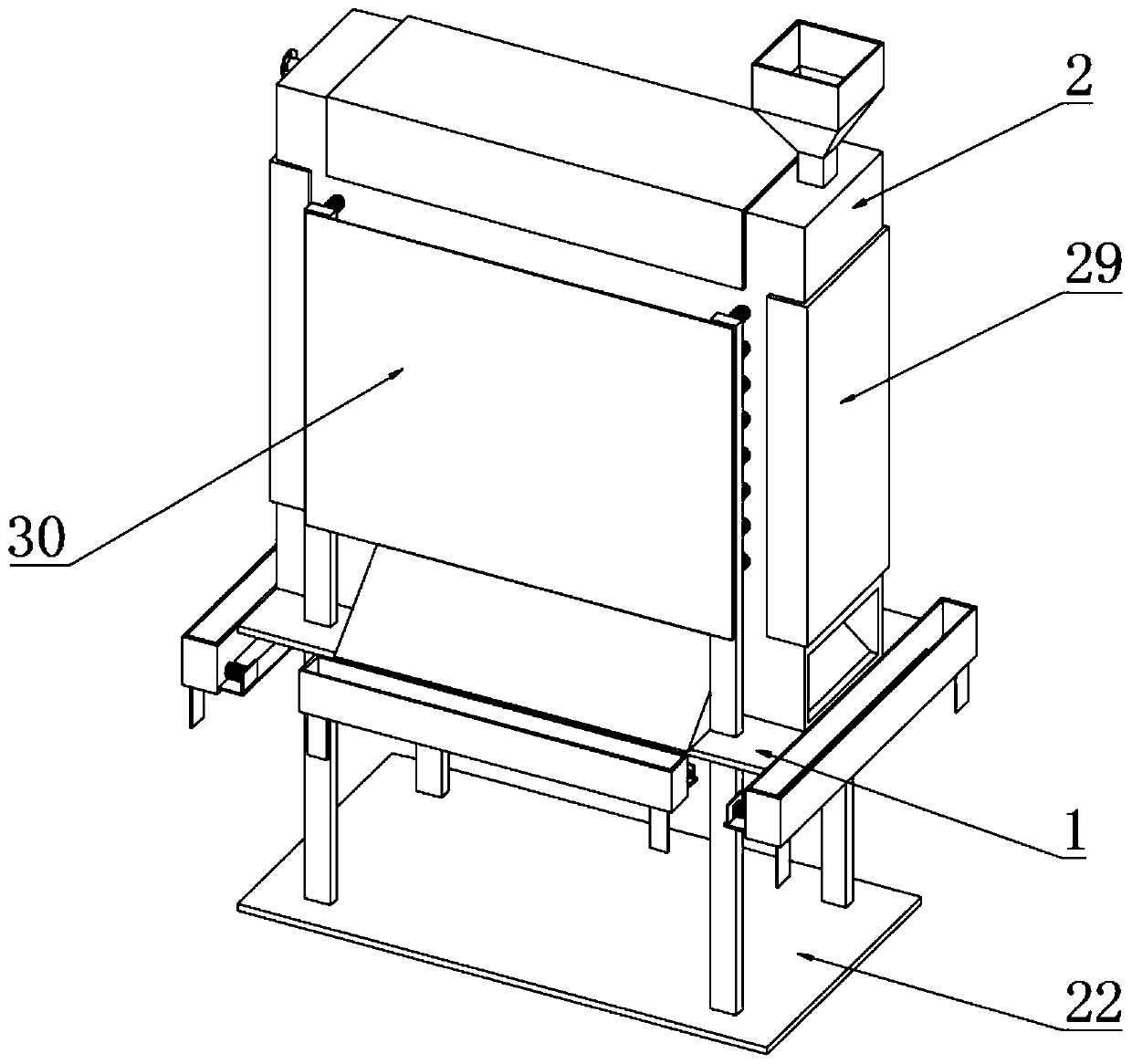

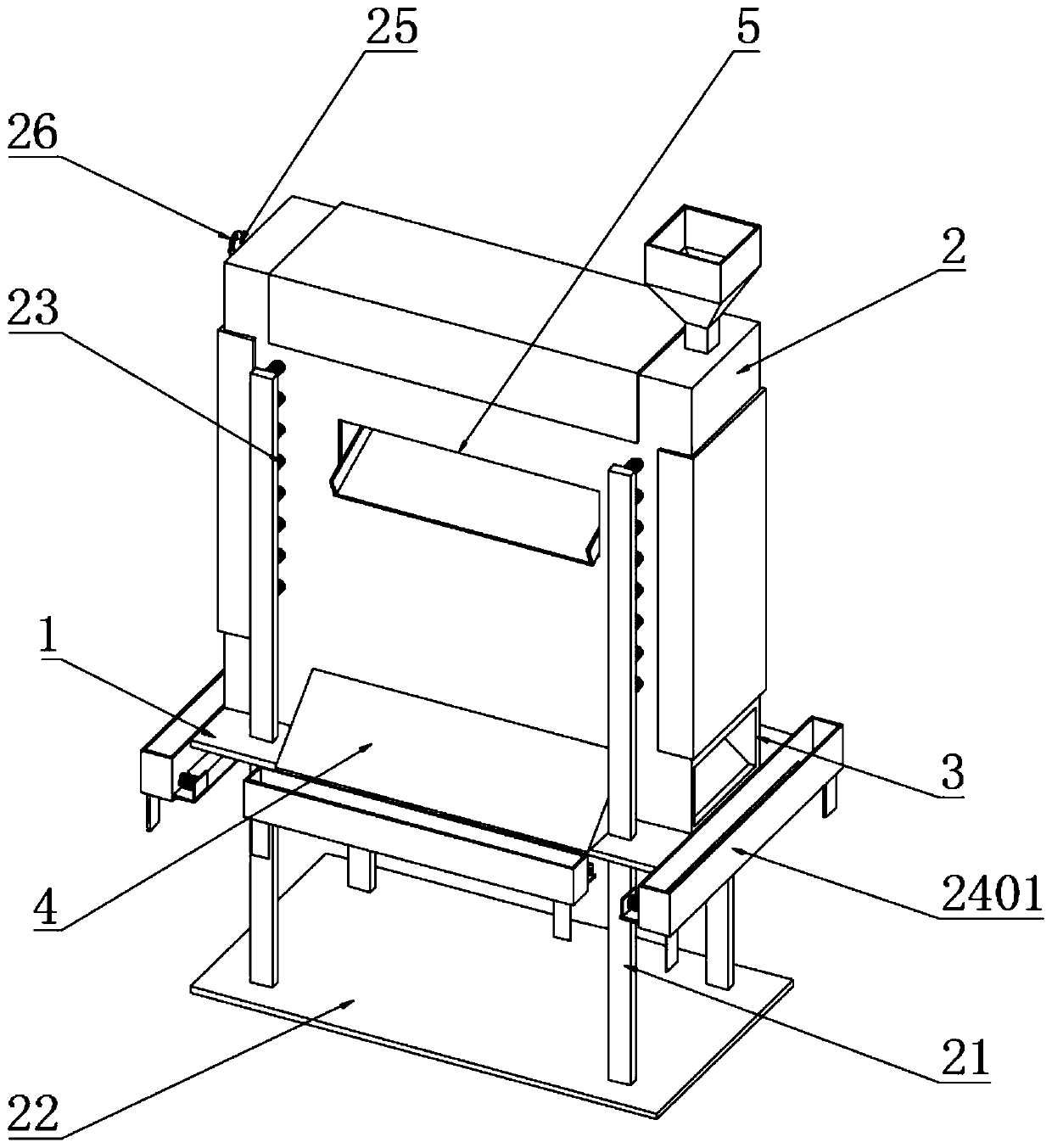

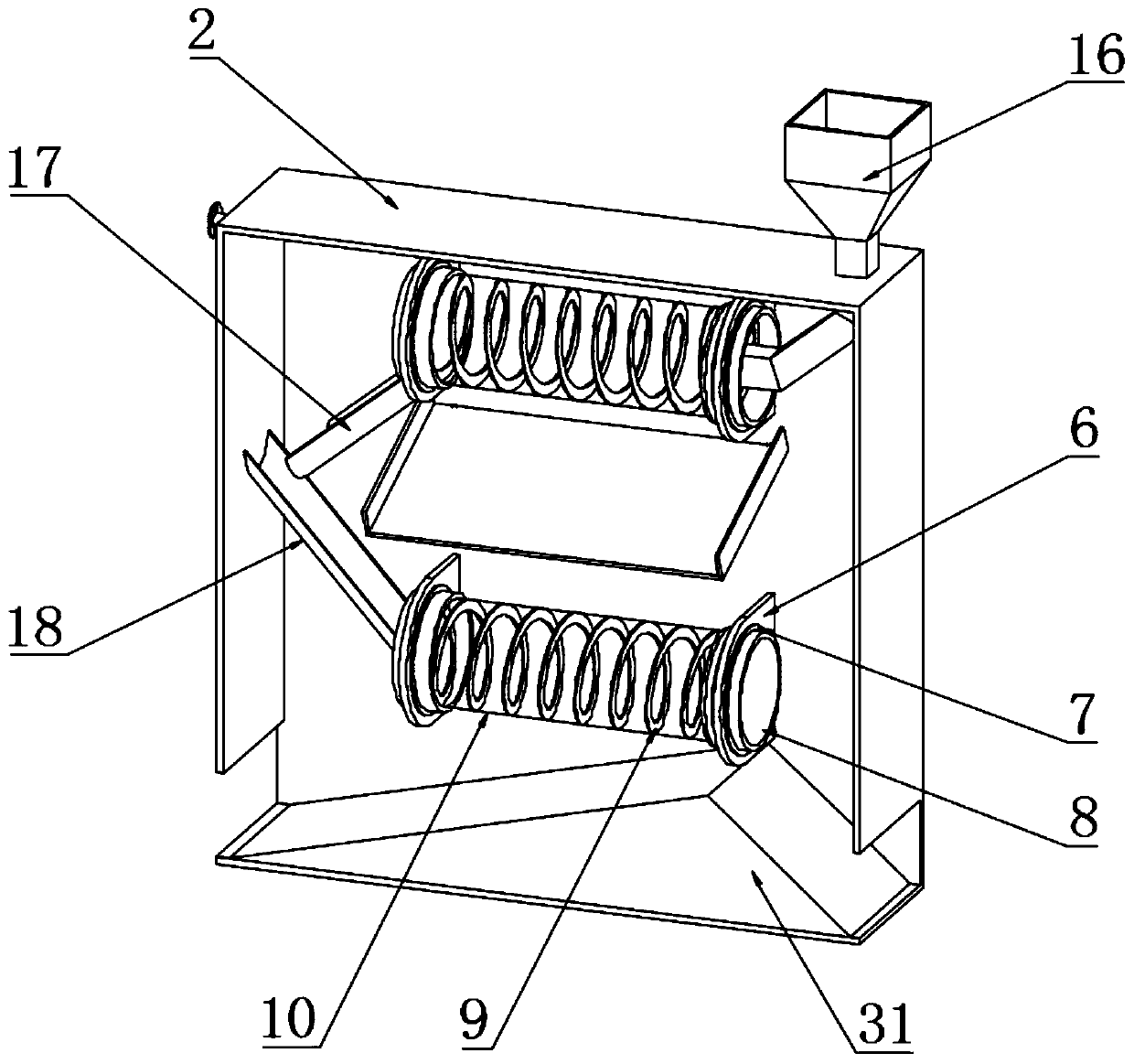

[0044] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, an integrated device for automatic sorting and collection of protective sandstone for mechanical engineering, including a supporting plate 1, a soundproof box 2 is welded in the middle of the top of the supporting plate 1, and the top of the soundproof box 2 The first sound-absorbing plate 29 is glued to the surfaces on both sides, and the top of the supporting plate 1 is penetrated and welded with a column 21 in a centrosymmetric manner. The structure of the sound-absorbing board 29 and the second sound-absorbing board 30 is the same, specifically including a foamed aluminum substrate 301, a gas-permeable membrane 302, a flexible pillar 303, and a side plate 304. The array of the flexible pillars 303 is arranged on the foamed aluminum substrate 301. The membrane 302 is connected to the other end of the flexible support 303 and the gas-permeable membrane 302 is provided with a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com