A two-degree-of-freedom extension type pipe cleaning robot support arm

A pipe cleaning and stretching technology, applied in the directions of manipulators, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of slippage and insufficient forward power of the rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

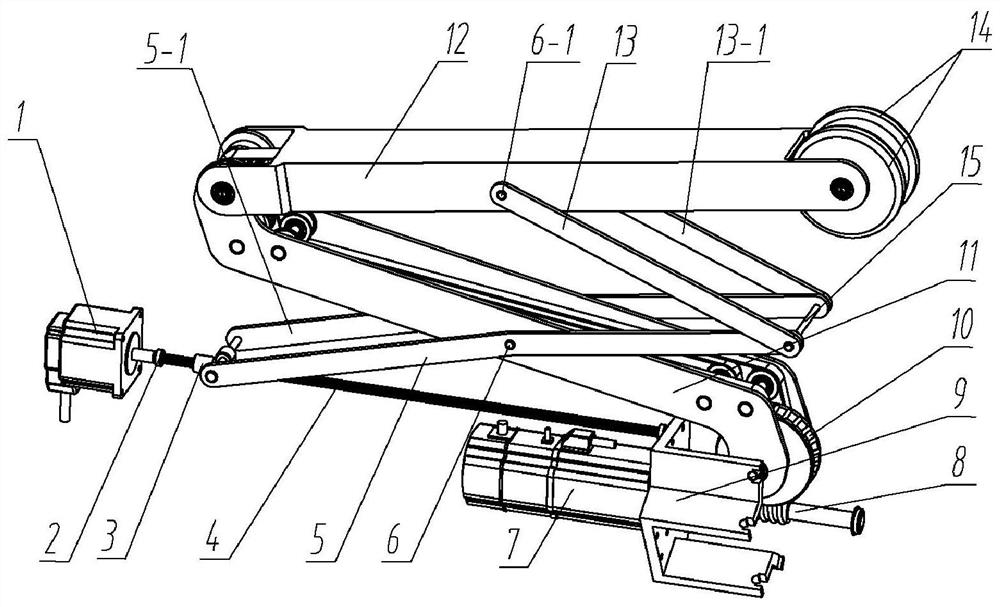

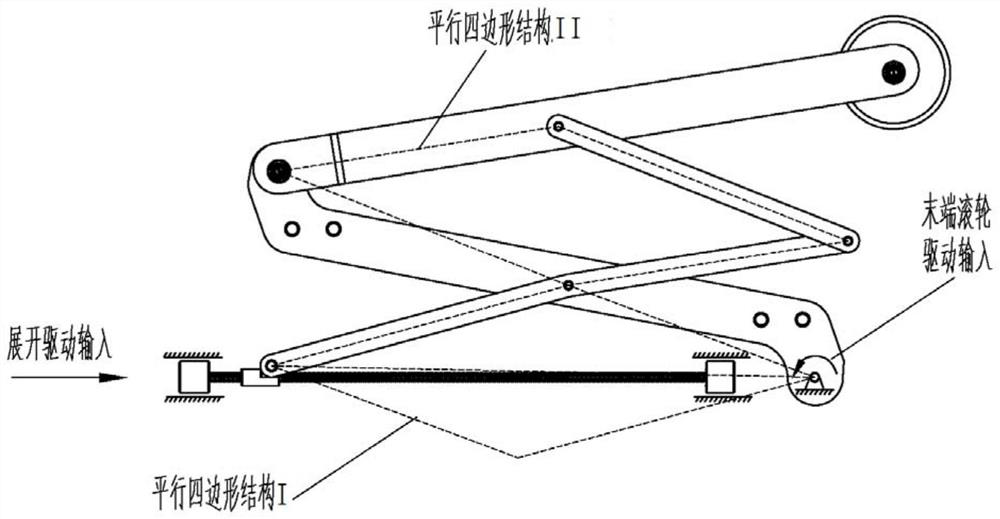

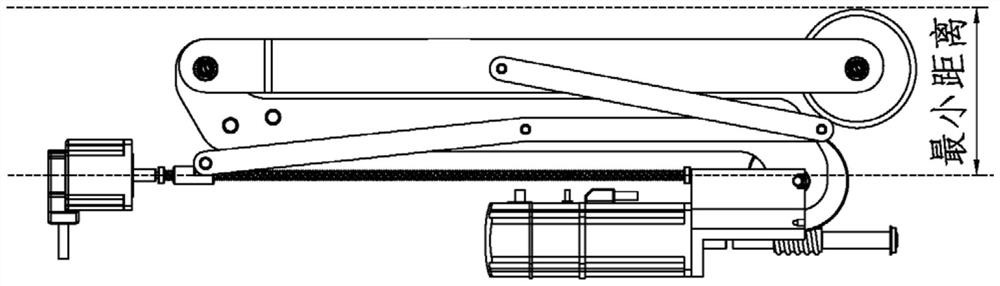

[0033] The two-degree-of-freedom extension type pipe cleaning robot support arm of the present invention will be described in detail below with reference to the drawings and embodiments.

[0034] A two-degree-of-freedom extension-type pipeline cleaning robot support arm of the present invention includes an extension-type mechanical arm based on a double parallelogram structure, and a roller driven by a synchronous belt at the end of the extension-type mechanical arm, and is used for the cleaning operation of the pipeline cleaning robot. Provides effective support and drive for movement within the pipe. The extended mechanical arm based on the double parallelogram structure is driven by a motor and a ball screw; the roller located at the end of the extended mechanical arm is driven by a motor and a worm gear.

[0035] A two-degree-of-freedom extension type pipe cleaning robot support arm of the present invention, the overall structure is as follows figure 1 shown.

[0036] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com