A method for forming an integral upper support structure of reactor internals

A support structure and integral technology, applied in the direction of additive processing, can solve the problems of long time period, complex welding process, large deformation, etc., and achieve the effect of shortening the manufacturing cycle, improving the forming quality, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

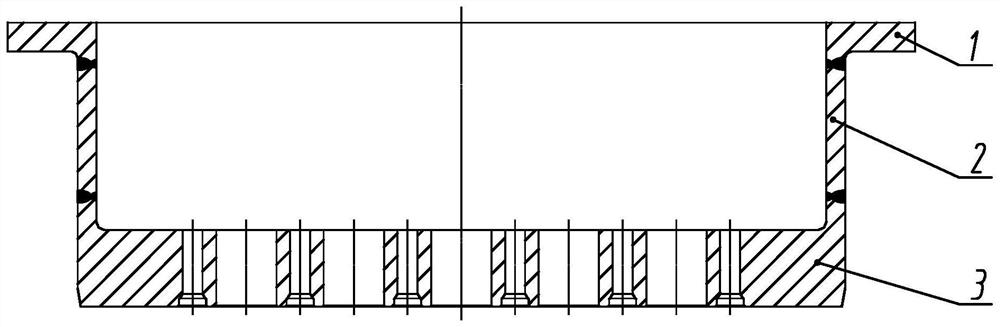

[0077] In the design of the upper support structure of the existing reactor internals, based on the assembly and welding process of each component, the upper support structure is divided into an upper support flange (1), a skirt (2) and an upper support plate (3), such as figure 1 . The skirt (2) is rolled into a cylindrical structure by sheet material, and is formed by full penetration welding along the axial direction of the cylindrical structure, and then the upper support flange (1), skirt (2) and upper support plate (3) are assembled Afterwards, circumferential full-penetration welding is performed to manufacture a complete upper support structure.

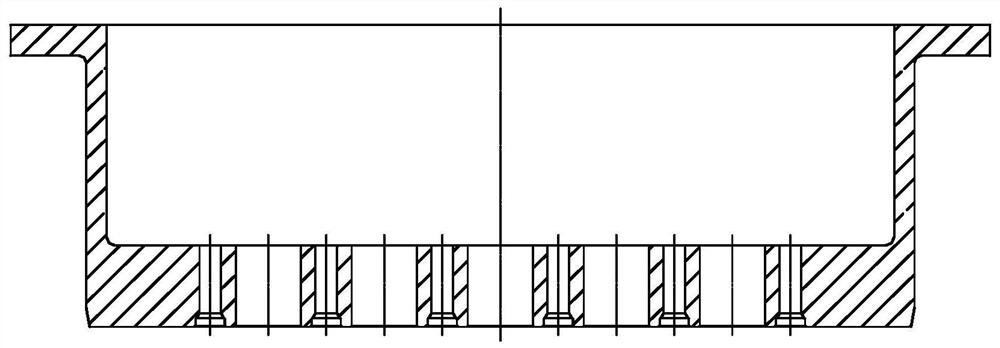

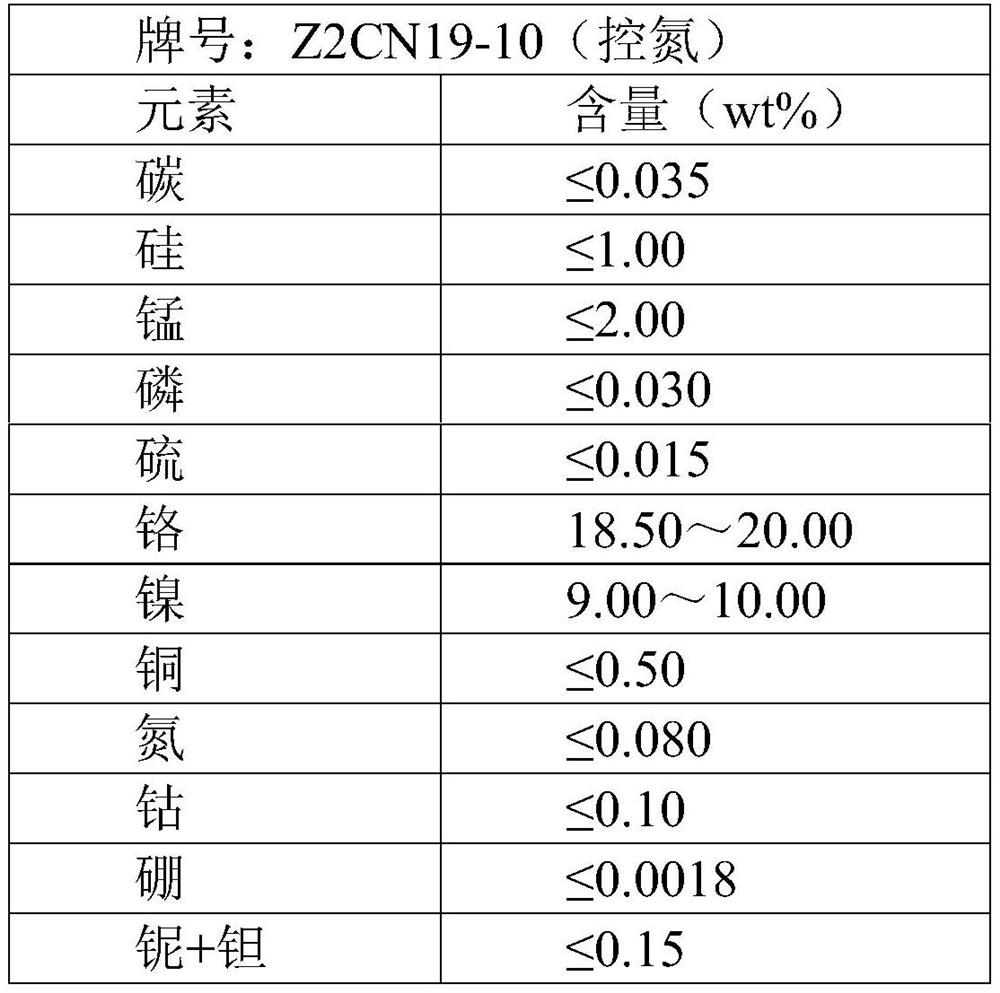

[0078] The present invention is based on the electro-fusion additive manufacturing technology, and designs the upper support structure as an integral structure, that is, cancels the connecting welds between the structures and the special requirements for raw materials such as forgings and plates. Based on the electro-fusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com