Phosphogypsum thermal insulation block and preparation process thereof

A thermal insulation block and preparation technology, which is applied in the field of building materials, can solve the problems affecting the use performance of houses, poor thermal insulation performance, waste of resources, etc., and achieve the effect of light weight, good seismic performance, and strong thermal insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

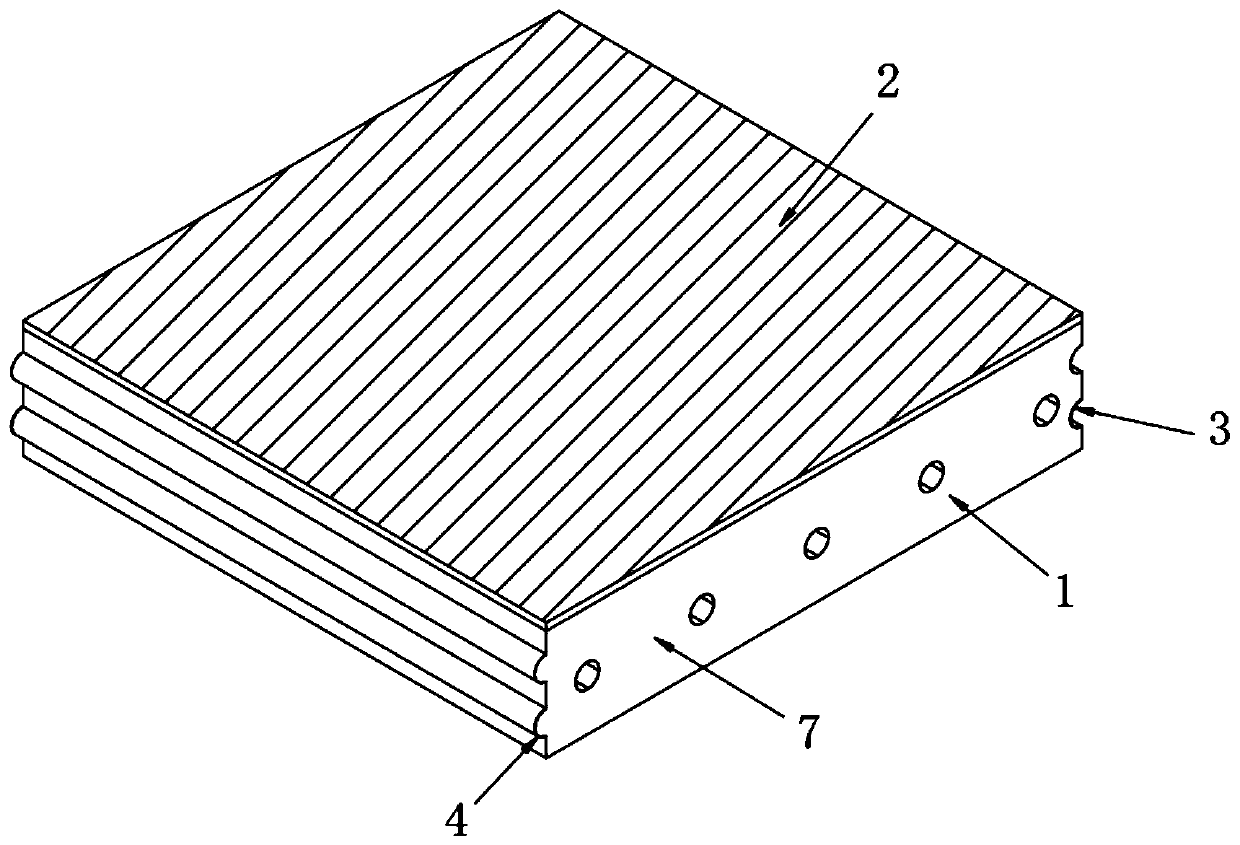

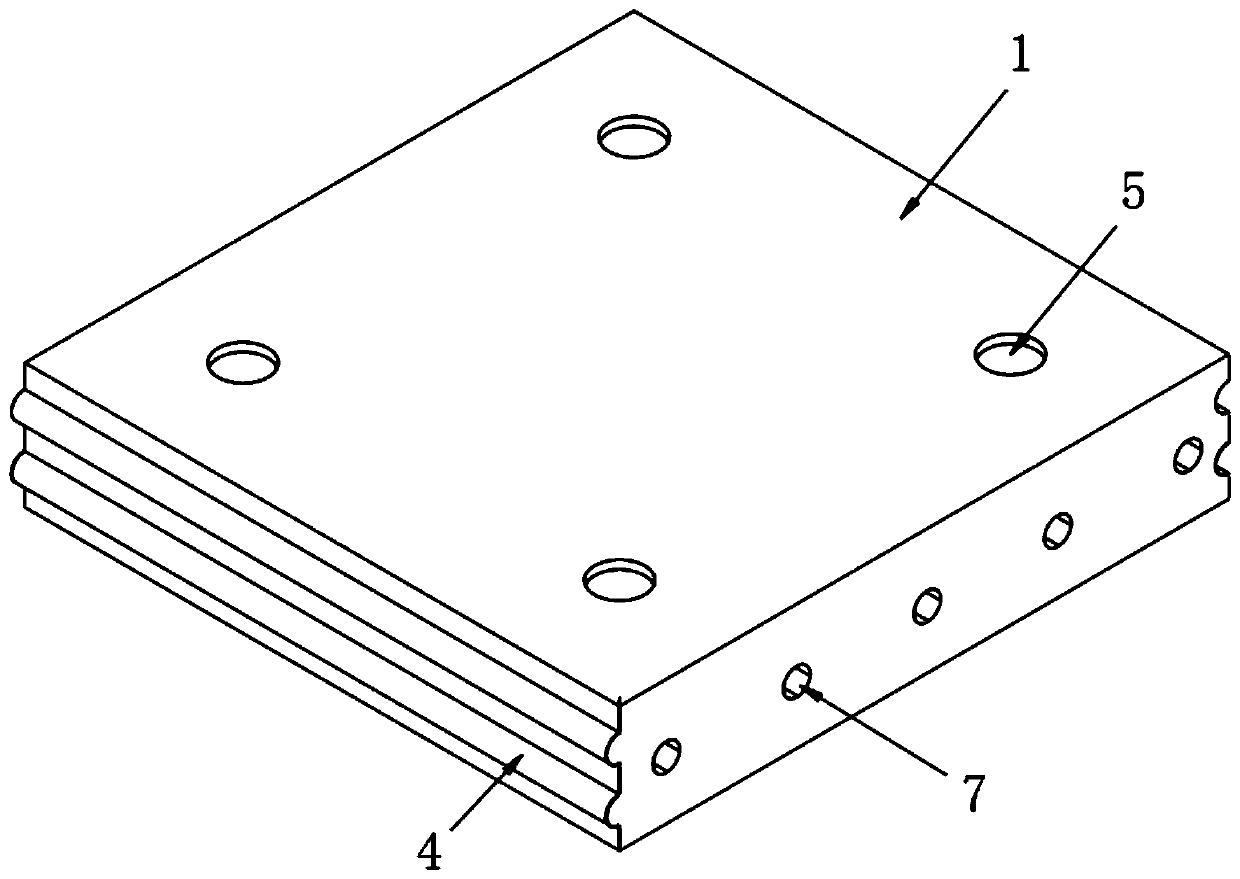

[0032] A phosphogypsum insulation block, such as figure 1 As shown, the block body 1 is included, the top of the block body 1 is provided with a decorative panel 2, the decorative panel 2 is adapted to the top area size of the block body 1, the decorative panel 2 is made of artificial plywood or artificial wood veneer, and the decorative panel The thickness of panel 2 is 0.5-3.0mm, preferably as the present embodiment, decorative panel 2 adopts man-made plywood, and thickness is 1.5mm, and plywood is to be cut into veneer by wood section or sliced into veneer by wood square, and then use A three-layer or multi-layer board-like material glued together with an adhesive is usually made of odd-numbered veneers, and the fiber directions of adjacent veneers are glued perpendicular to each other to retain the natural color and texture of the wood surface. You can choose the panel material , patterns and colors, plywood is natural, simple, natural, beautiful and noble, and can creat...

Embodiment 2

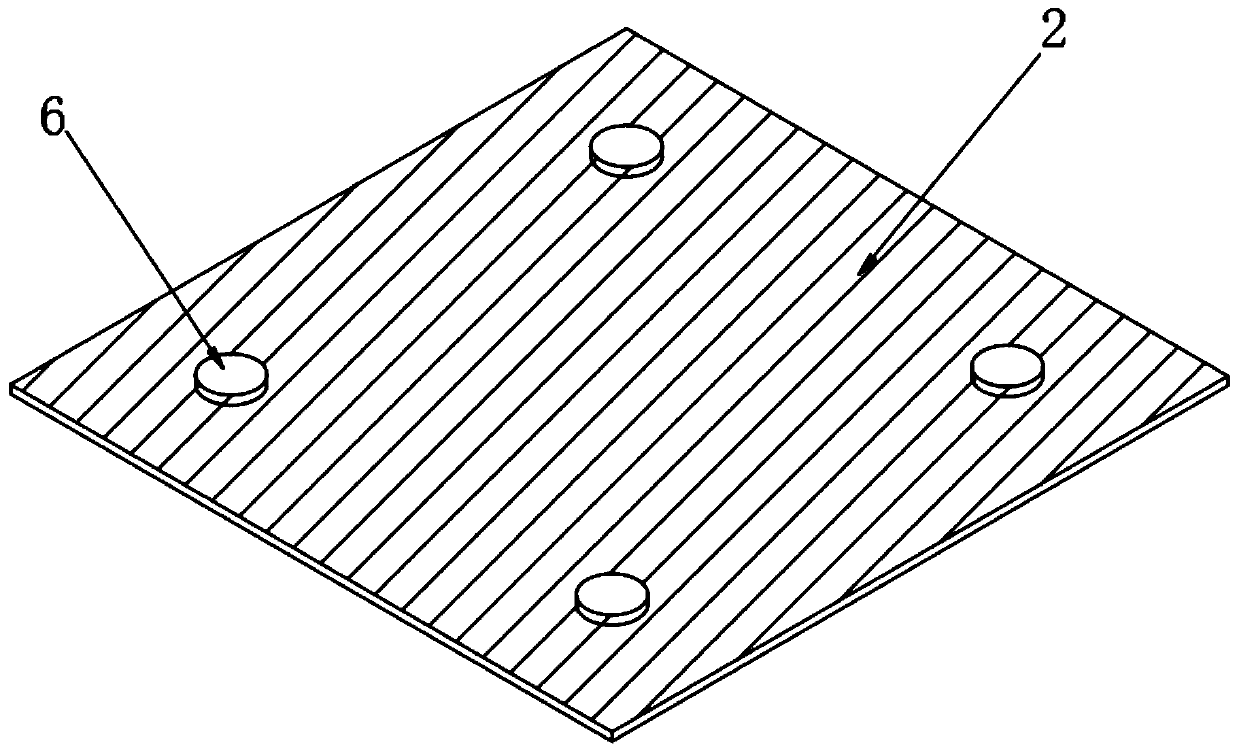

[0047] As a second embodiment of the present invention, such as figure 2 with image 3 As shown, the top surface of the block body 1 is provided with a number of evenly spaced and rectangularly arranged decorative plate fixing grooves 5, and the bottom surface of the decorative panel 2 is equipped with a number of uniformly equidistantly rectangularly arranged decorative plate connecting columns 6, and the decorative plate The position of the connecting column 6 is corresponding to the fixing groove 5 of the decorative plate, and the size is matched, and the connecting column 6 of the decorative plate is plugged and matched with the fixing groove 5 of the decorative plate, so as to facilitate fixing the decorative panel 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com