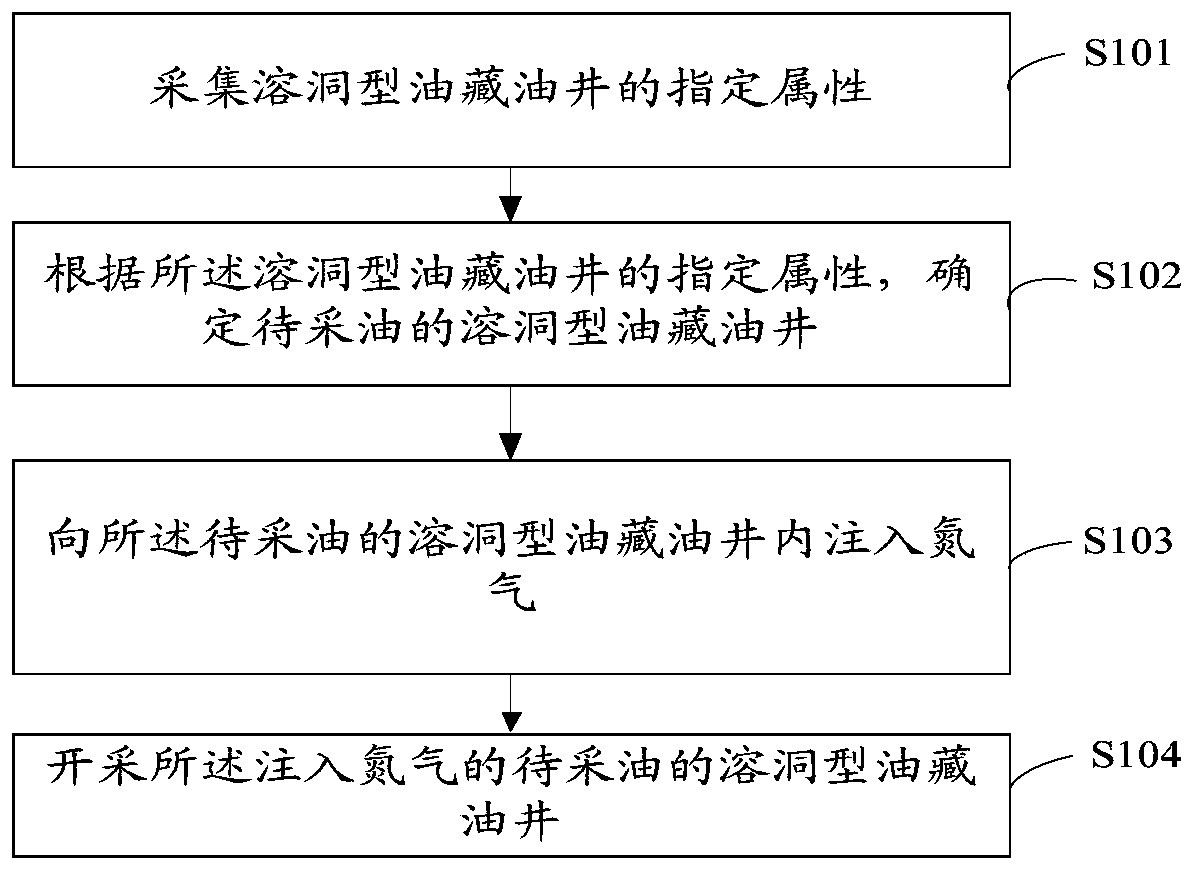

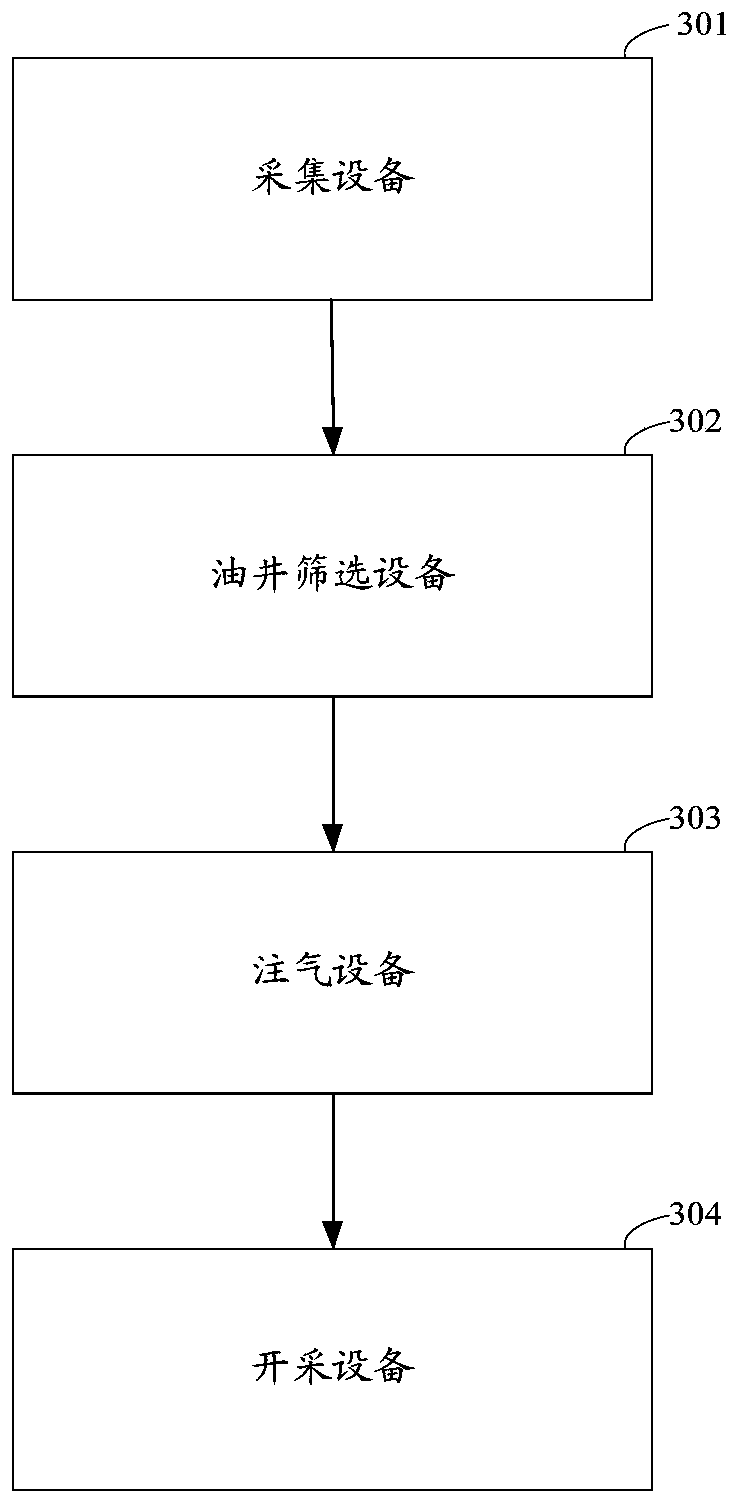

Karst cave type oil reservoir oil well nitrogen injection oil extraction method and system

A technology of karst cave type and oil well, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of complex oil-water relationship, complex connection relationship of storage space, and no unified oil-water interface, etc., to improve the replacement efficiency , Improve the effect of single well productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] In addition, the determination of the cave-type oil wells to be produced needs to be determined according to the type of specified attributes. That is to say, if the types of specified attributes collected are different, the determined wells to be produced in cave-type oil reservoirs will be different. In this embodiment of the present application, in combination with the types of the above-mentioned three specified attributes, the following three implementations are given to determine the karst-cavern reservoir oil well to be produced according to the specified attribute of the karst-vug reservoir oil well, specifically as follows:

[0029] The first implementation mode: when the specified attributes include: seismic body anomalies within the first preset range from the oil well and drilling vent bottom loss, there will be seismic volume anomalies within the first preset range from the oil well and drilling vent bottom loss The oil well is determined to be the oil well ...

Embodiment 1

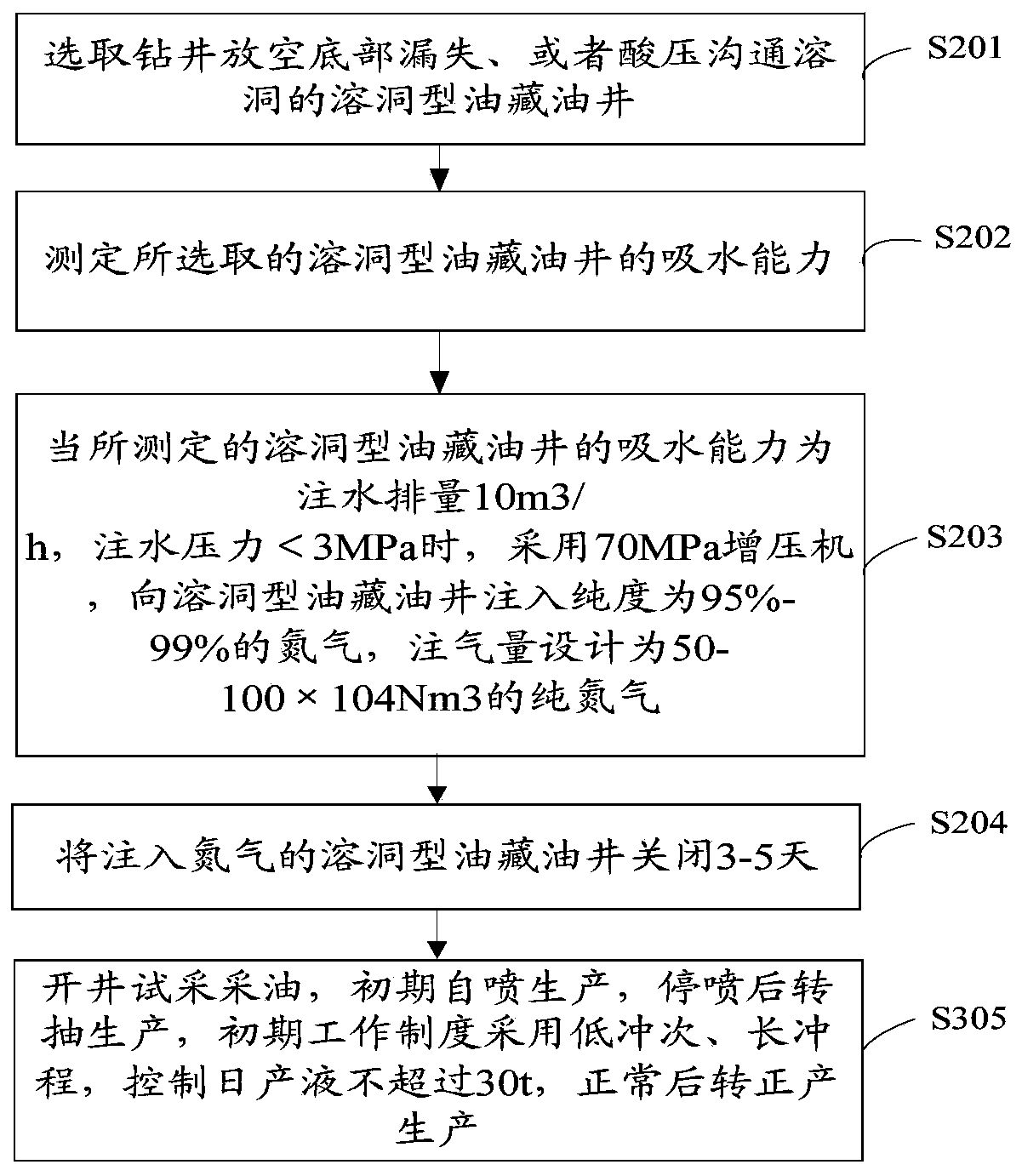

[0060] Well 1# in Tahe Oilfield is located in a structural remnant hill, with local structural highs around the well, and large-scale reservoirs developed, with crude oil geological reserves reaching 62×104m3. The acid fracturing cave was put into production in May 1999, and the initial daily crude oil production was 500t. However, with the development, the oil-water interface moved up, which made it difficult to recover the remaining oil in the high part above the overflow outlet around the well. In May 2011, the oil well flooded violently, with a high water cut of 99.9%. From April 11th to 22nd, 2012, 55×104Nm3 nitrogen gas was injected. On April 24th, the 3mm choke nozzle was opened for evaluation. From production to January 2013, the water cut was again high, and the cumulative oil increase was 1658t.

Embodiment 2

[0062] Well 2# in Tahe Oilfield is located in a structural remnant hill, 20m away from the top layer of the Ordovician system, and was drilled and vented. Large-scale reservoirs were developed, and the crude oil geological reserves reached 58×104m3. The conventional well was completed and put into production in June 2006, and the initial daily crude oil production was 120t. However, with the development, the oil-water interface moved up, making it difficult to recover the remaining oil in the high part above the overflow outlet around the well. In May 2013, the oil well was flooded violently, with a high water cut of 98%. From June 10th to 20th, 2013, 80×104Nm3 nitrogen gas was injected. On June 22nd, the 6mm choke nozzle was opened for evaluation. From production to August 2013, the water cut was again high, and the cumulative oil increase was 1870t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com