Direct-connected multi-piece friction power take-off

A technology for power take-offs and friction plates, which is applied in the field of direct-connected multi-plate friction power take-offs, can solve the problems of increasing the lateral space occupied by the power take-off, high rotational friction of the input shaft, and many materials used in the production of the power take-off. The effect of simple structure, increased transmission efficiency, and ease of manufacture and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

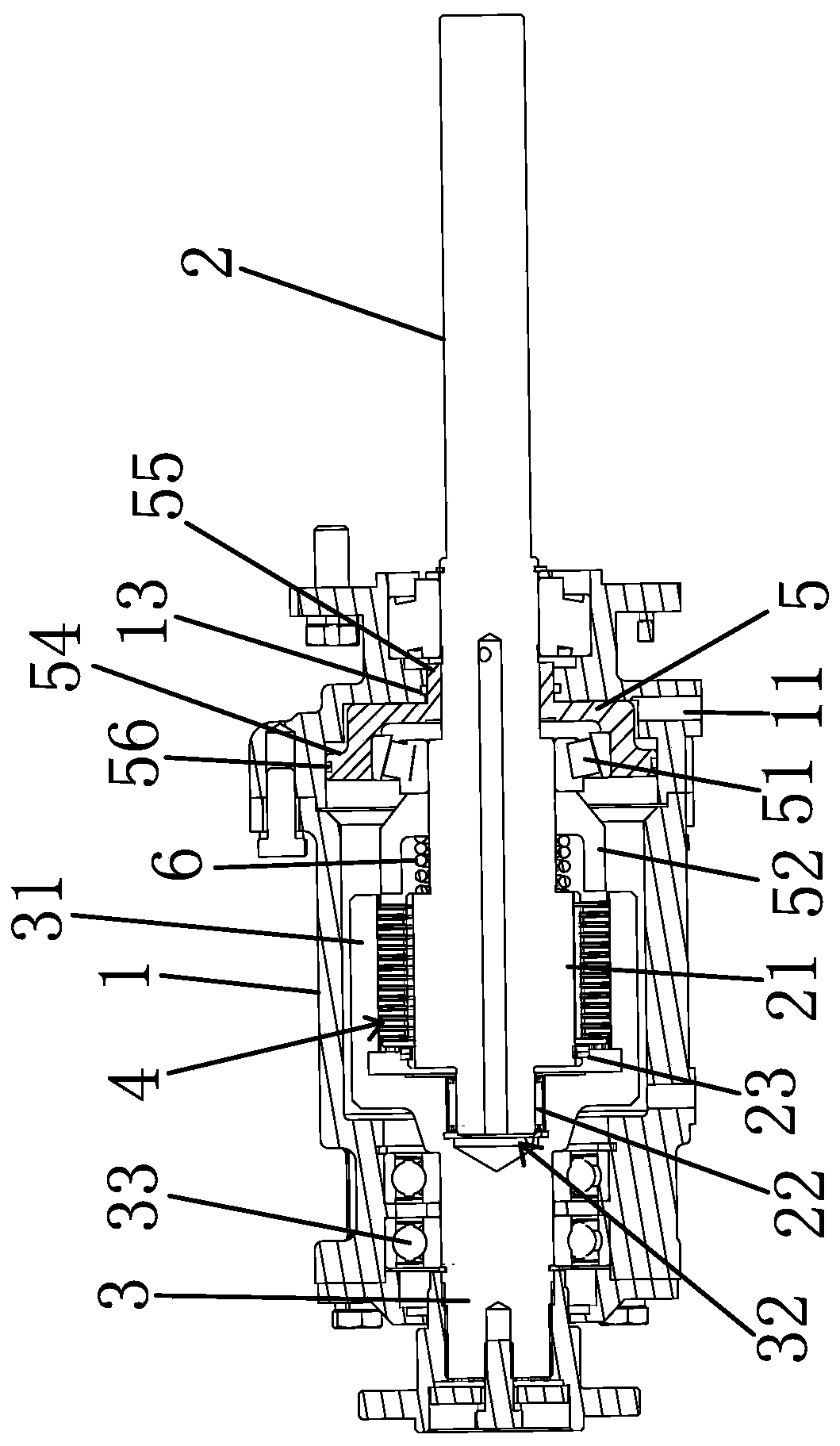

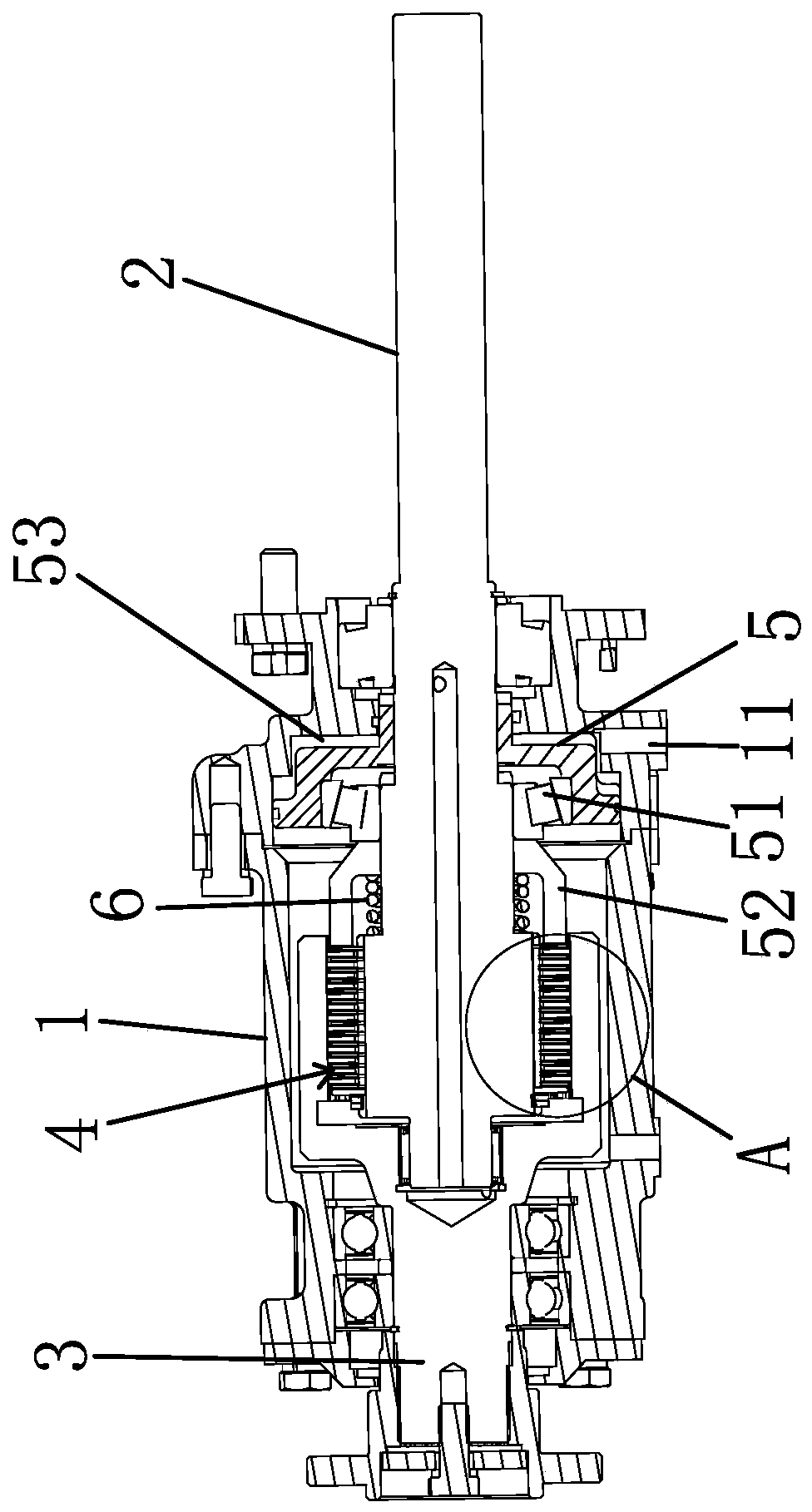

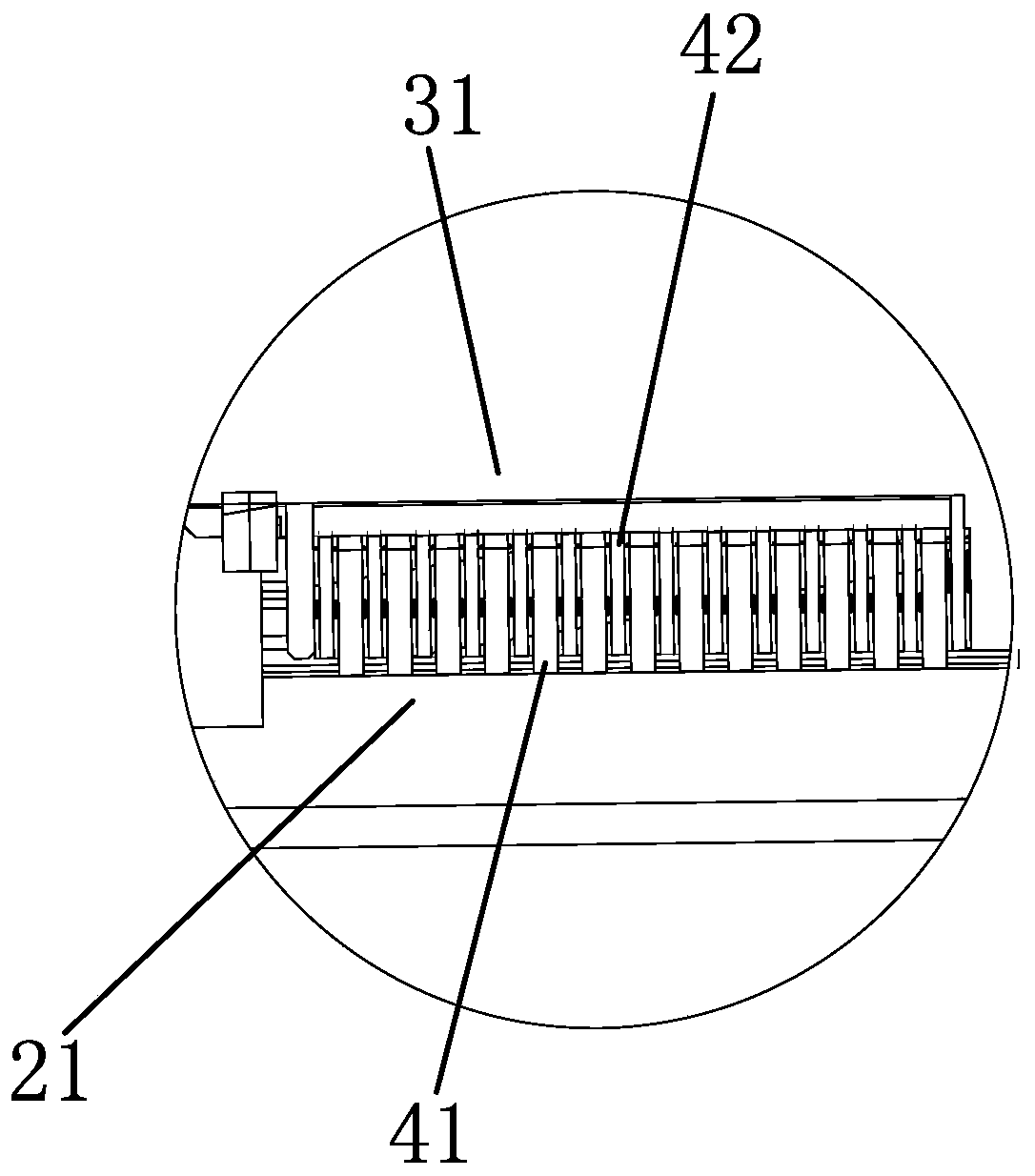

[0033] Such as Figure 1-2 As shown, the direct-connected multi-disc friction power take-off includes a cylindrical shell 1 and two ends of the shell 1 are respectively provided with an input port and an output port, and an input shaft 2 is penetrated in the shell 1 and input One end of the shaft 2 protrudes from the input port, an output shaft 3 is pierced in the housing 1 and one end of the output shaft 3 protrudes from the output port, and one end of the output shaft 3 is coaxially sleeved on the input shaft 2 end The inner spline connection part on the inner spline connection part, the outer spline connection part 21 corresponding to the inner spline connection part is provided on the outer side of the input shaft 2, and the inner spline connection part is provided with the input shaft 2 ends The positioning hole for snapping in, the input bearing one 22 is arranged in the positioning hole and is located on the circumferential outer side of the end of the input shaft 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com