Electromagnetic interference resisting electric gearbox

An anti-electromagnetic interference and gearbox technology, which is applied to transmission parts, components with teeth, transmission control, etc., can solve the problems of large transmission size, magnetization of active parts, and potential safety hazards, etc., to achieve small wear and tear. Low power consumption, good anti-electromagnetic interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

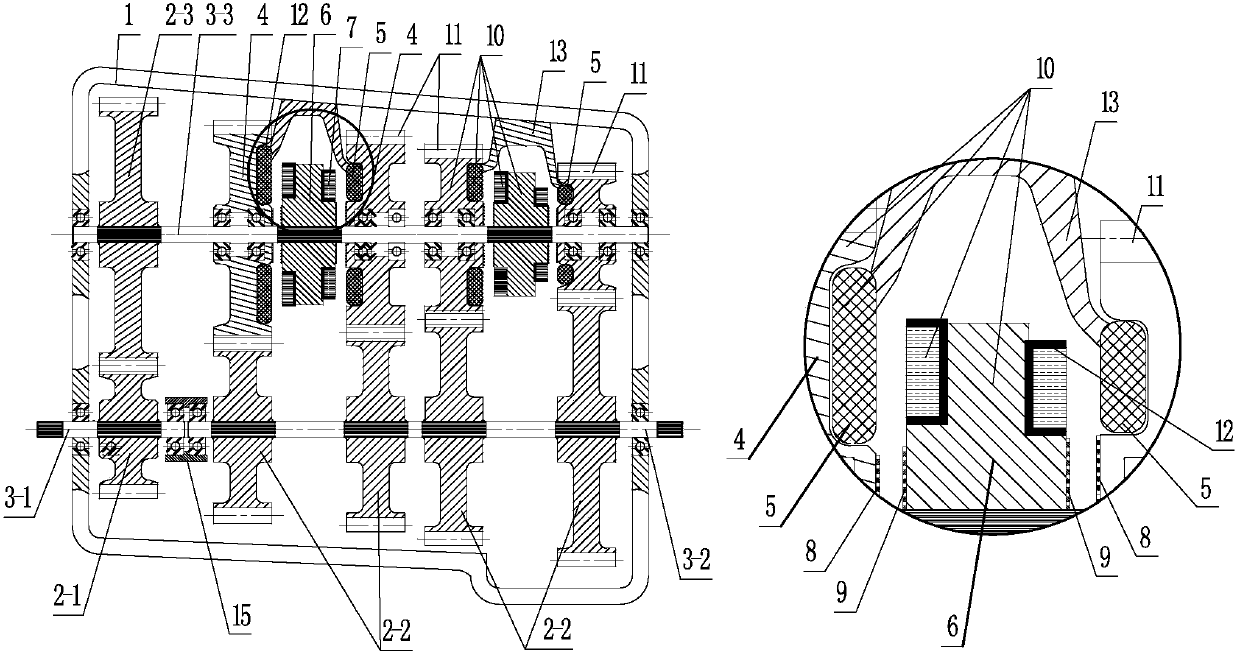

[0062] Such as figure 1 and figure 2 As shown, an anti-electromagnetic interference electric transmission according to the present invention includes a housing 1 , a gear 2 , a shaft 3 and an electric transmission assembly 10 . Shaft 3 includes input shaft 3-1, output shaft 3-2 and intermediate shaft 3-3, input shaft 3-1 and output shaft 3-2 are connected by needle bearing 15, input shaft 3-1, output shaft 3-2 The input shaft gear 2-1, the output shaft gear 2-2 and the intermediate shaft gear 2-3 are fixedly provided with the input shaft gear 2-1 rotating with the shaft 3 by keys respectively on the intermediate shaft 3-3.

[0063] Two sets of electric transmission assemblies 10 are also arranged on the intermediate shaft 3-3. One set of electric transmission assemblies 10 includes a key slider 6 and two shaft gears 4, and the key slider 6 is located between the two shaft gears 4, so that the present An anti-electromagnetic interference electric transmission of the embodime...

Embodiment 2

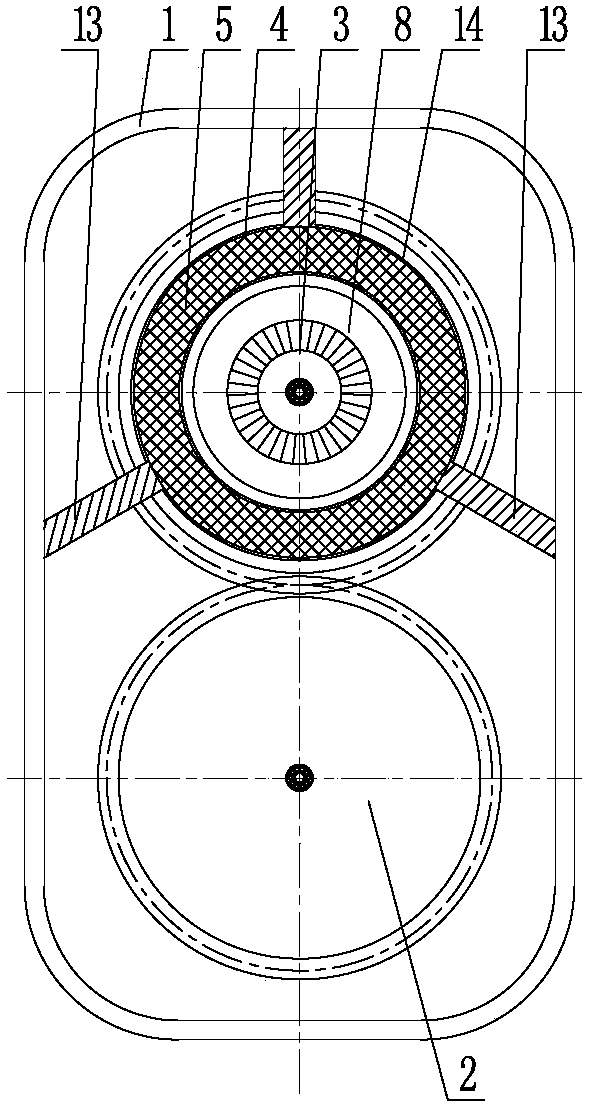

[0068] Figure 8 It is the schematic diagram of embodiment two. The difference between the second embodiment and the first embodiment mainly lies in that the intermediate shaft 3-3 of the second embodiment is only provided with a set of electric transmission components 10, and one set of electric transmission components 10 includes a key slider 6 and two shaft gears 4, The key slider 6 is located between the two shaft gears 4, so that the anti-electromagnetic interference electric transmission of this embodiment has two gears.

Embodiment 3

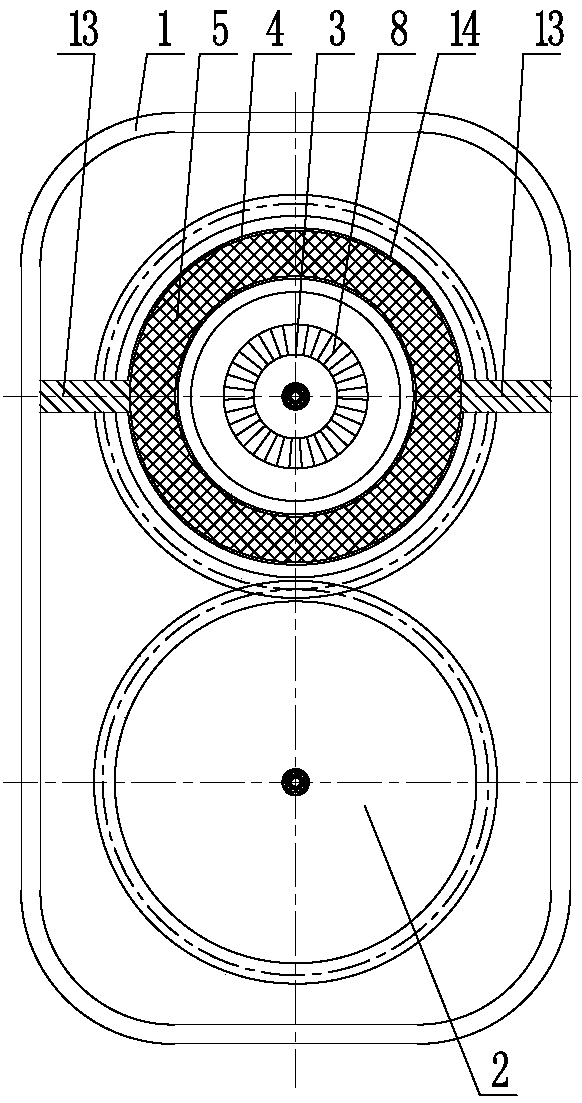

[0070] Figure 9 It is the schematic diagram of embodiment three. The difference between the third embodiment and the first embodiment mainly lies in that the intermediate shaft 3-3 of the third embodiment is only provided with a group of electric transmission components 10, and two different intermediate shaft gears 2-3 are added, and the input shaft 3-2 A set of electric transmission assembly 10 is added, and the two rotating shaft gears 4 of the additional electric transmission assembly 10 mesh with the two additional countershaft gears 2-3 on the intermediate shaft 3-3 respectively. In this way, the anti-electromagnetic interference electric transmission of this embodiment has four gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com