Micro electro mechanical system (MEMS) chip structure

A technology of chip structure and ring structure, which is applied in the field of MEMS chips, can solve the problems of performance degradation and complicated control of micromirrors, and achieve the effect of reducing the influence of thermal crosstalk, small size and more volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

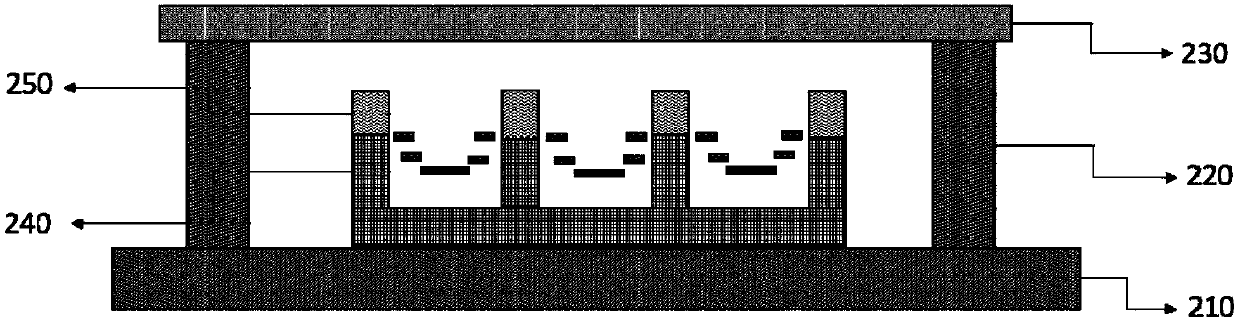

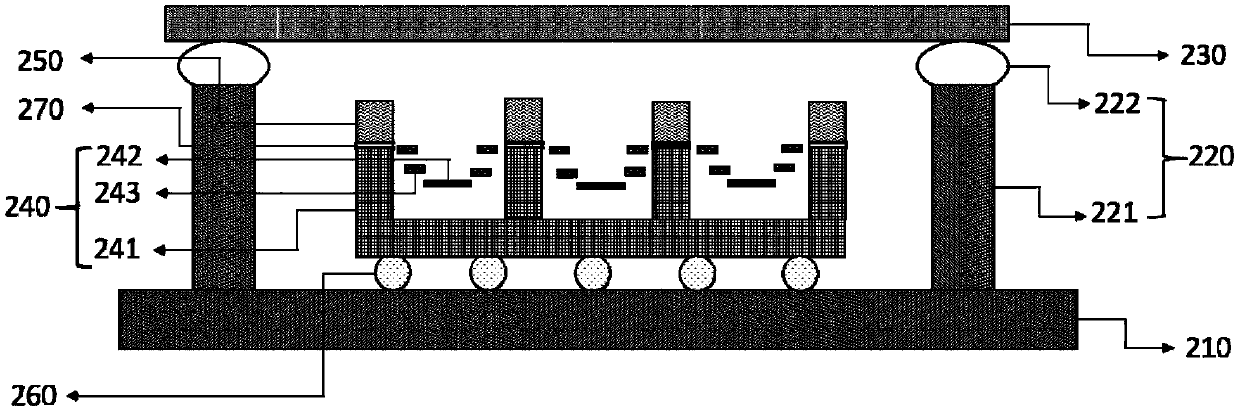

[0037] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

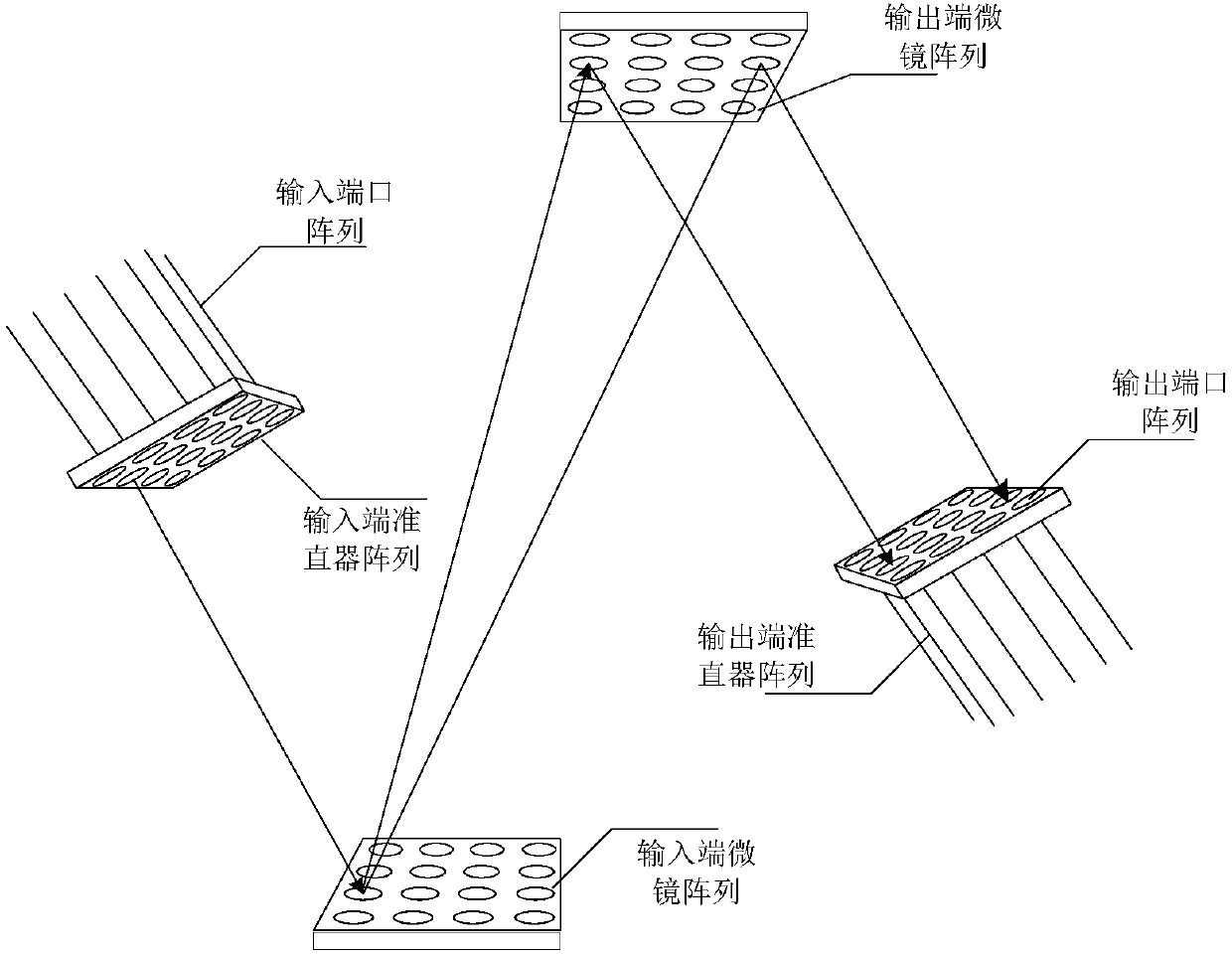

[0038] The application relates to a MEMS chip structure, which is a core device constituting an optical switch in the field of optical switching. figure 1A schematic block diagram of a MEMS optical switch is shown, including an input port array, an input micromirror array, an output micromirror array, and an output port array, wherein the input port array is used to receive optical signals; the input The micromirror array at the end reflects the received optical signal to the micromirror array at the output end; the micromirror array at the output end reflects the optical signal reflected by the micromirror array at the input end to the output port array, thereby sending it out; wherein, the micromirror array at the input end or The micromirrors included in the micromirror array at the output end ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com